Hollow manipulator

A manipulator, hollow technology, applied in the direction of manipulator, program control manipulator, chuck, etc., can solve the problems of no reserved space for installing expansion equipment, single structure, inconvenient manipulator optimization and expansion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

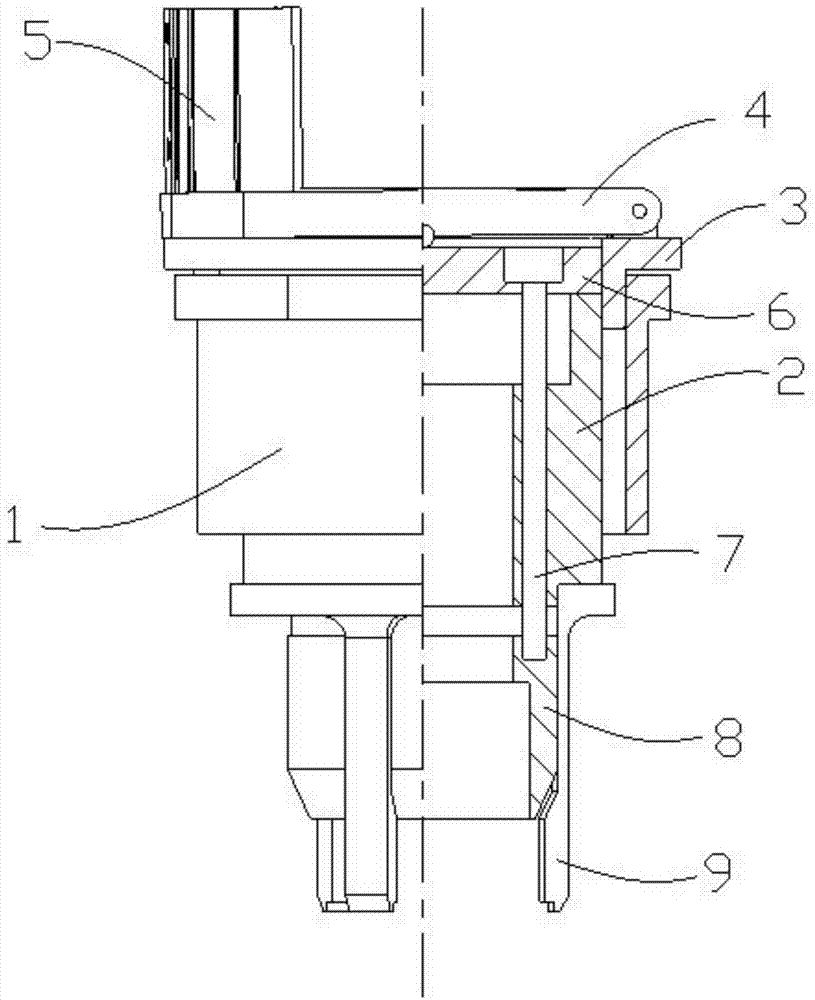

[0029] see figure 1 , is a schematic diagram of the half-section structure of the first embodiment of the hollow manipulator of the present invention. In the figure, the center line of the hollow manipulator is used as the dividing line, and the right side of the center line is sectioned to clearly observe the internal structure of the hollow manipulator. A hollow manipulator includes: an outer shell 1, an inner sleeve 2, a hinge frame 3, a top cover 4, a control cylinder 5, a top plate 6, connecting bolts 7, a hollow taper sleeve 8 and elastic gripper jaws 9.

[0030] The shell 1 protects the internal structure and connects with external devices.

[0031] The inner sleeve 2 is used to guide the connecting bolt 7 and is an important part inside the hollow manipulator; the inner sleeve 2 is installed inside the outer shell 1 .

[0032] The hinge frame 3 is used for installing the top cover 4 and the control cylinder 5; the hinge frame 3 is rigidly connected with the inner sle...

Embodiment 2

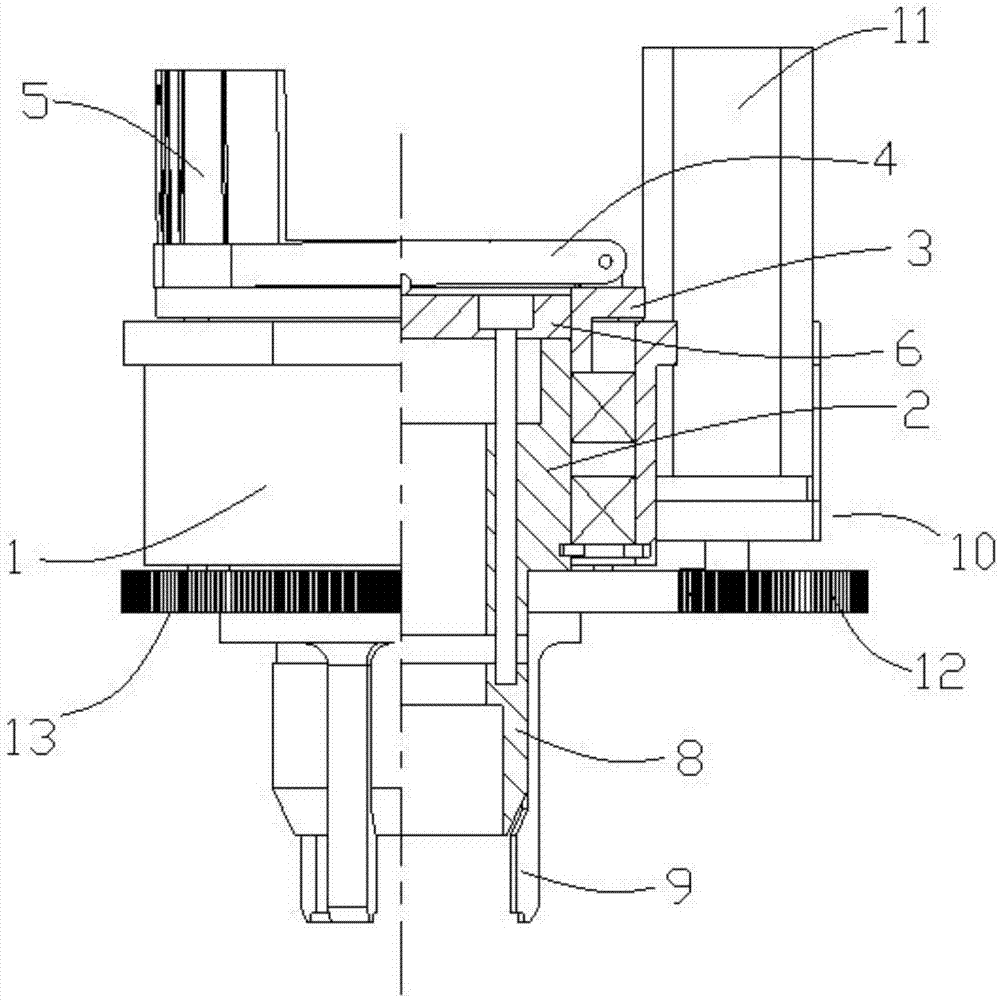

[0044] The difference from Embodiment 1 is that: on the original basis, a bearing and a rotating mechanism 10 are added, so that the hollow manipulator of the present invention has a rotating function.

[0045] see figure 2 , is a schematic diagram of the half-section structure of the second embodiment of the hollow manipulator of the present invention. In the figure, the center line of the hollow manipulator is used as the dividing line, and the right side of the center line is sectioned to clearly observe the internal structure of the hollow manipulator. In order to make the hollow manipulator of the present invention have the function of rotation, in this embodiment, the hollow manipulator of the present invention also includes a bearing (not shown) and a rotating mechanism 10; the bearing is installed between the inner sleeve 2 and the outer shell 1; the rotating mechanism 10 is installed on the outside of enclosure 1.

[0046] Rotating mechanism 10 comprises: rotating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com