Adjustable automatic machining device with continuous sample feeding function

A processing device and adjustable technology, applied in the direction of metal processing equipment, metal processing machinery parts, manufacturing tools, etc., can solve the problem of inability to adjust the height of the processing mechanism, and achieve the effect of solving the inconvenience of position adjustment, realizing cleaning, and avoiding contamination of workpieces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

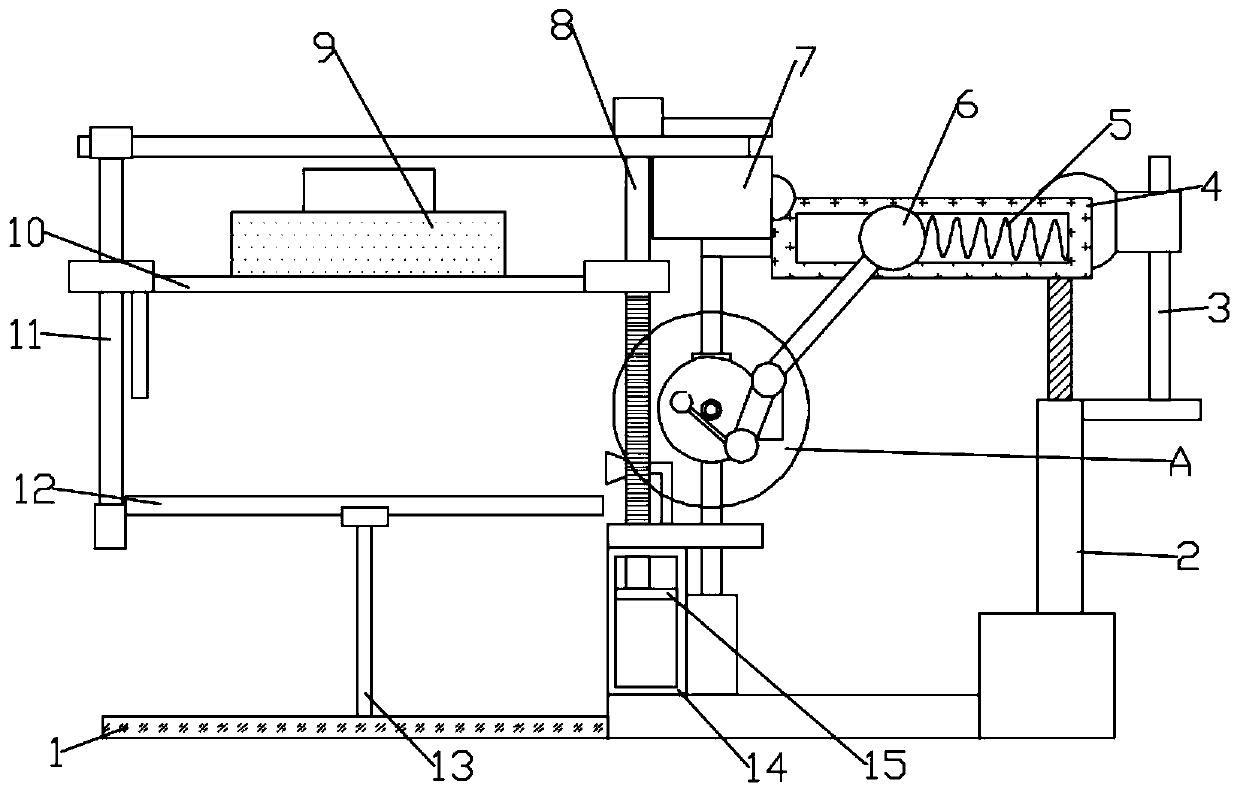

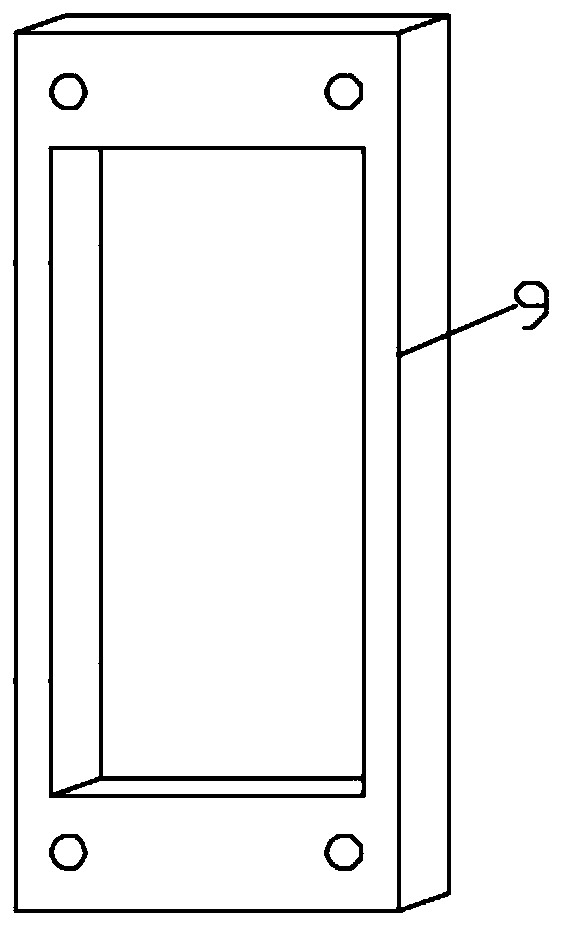

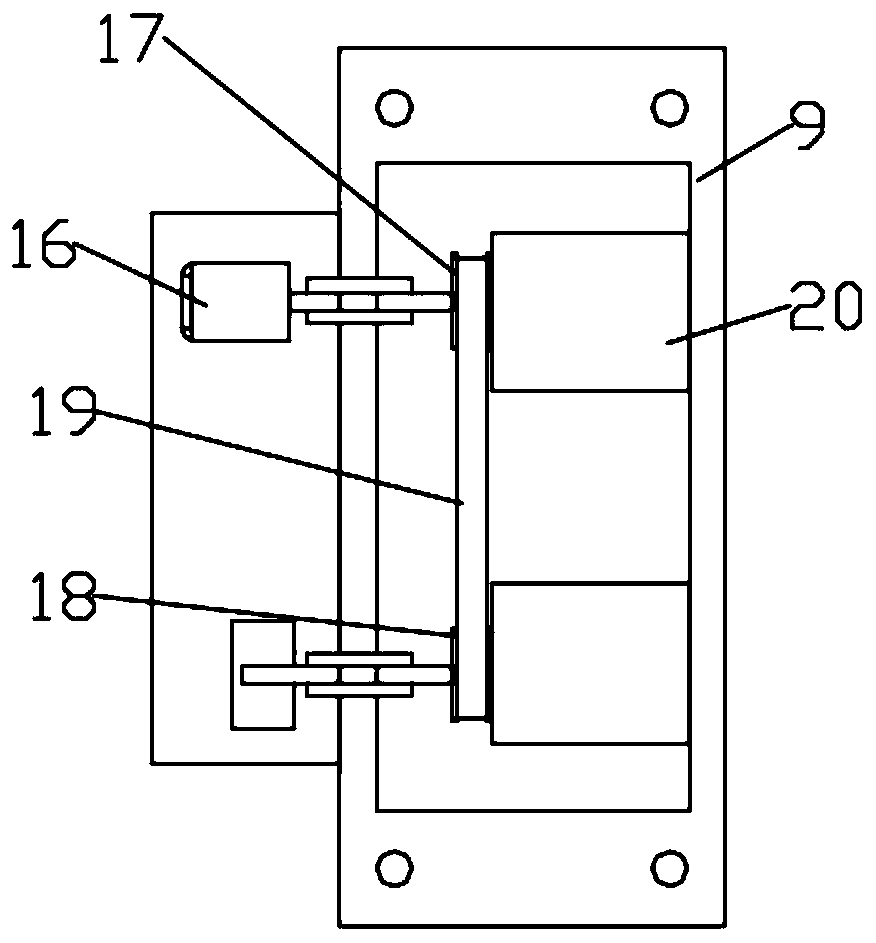

[0022] Such as figure 1 As shown, in the embodiment of the present invention, an adjustable automatic processing device for continuous sampling includes a base 1, a workbench 9 and a workpiece placement plate 12, and the top of the base 1 is provided with a workpiece placement plate 12 for placing workpieces. The placing plate 12 and the base 1 are fixedly connected by a column 13, a workbench base 10 is arranged above the workpiece placing plate 12, a workbench 9 is fixedly installed on the workbench base 10, and a processing assembly is arranged inside the workbench 9. The upper right of the base 1 is provided with a height adjustment mechanism for adjusting the height of the workbench 9;

[0023] Such as Figure 4 As shown, the height adjustment mechanism includes a driving cylinder 2, a buffer spring 5 and a gear 24, the bottom of the driving cylinder 2 is fixed on the base 1, the telescopic end of the driving cylinder 2 is hinged with a movable groove 4, and the movable ...

Embodiment 2

[0029] Such as figure 1 As shown, in the embodiment of the present invention, an adjustable automatic processing device for continuous sampling includes a base 1, a workbench 9 and a workpiece placement plate 12, and the top of the base 1 is provided with a workpiece placement plate 12 for placing workpieces. The placing plate 12 and the base 1 are fixedly connected by a column 13, a workbench base 10 is arranged above the workpiece placing plate 12, a workbench 9 is fixedly installed on the workbench base 10, and a processing assembly is arranged inside the workbench 9. The upper right of the base 1 is provided with a height adjustment mechanism for adjusting the height of the workbench 9;

[0030] Such as Figure 4 As shown, the height adjustment mechanism includes a driving cylinder 2, a buffer spring 5 and a gear 24, the bottom of the driving cylinder 2 is fixed on the base 1, the telescopic end of the driving cylinder 2 is hinged with a movable groove 4, and the movable ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com