Container modular organic fuel gas or smoke gas tail gas treatment device

A tail gas treatment, modular technology, applied in the direction of gas treatment, combined devices, combustion methods, etc., can solve the problems of large investment, large land occupation, large system wind resistance, etc., and achieve the effect of saving investment, occupying less land, and no need for workshops

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The principles and features of the present invention are described below, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

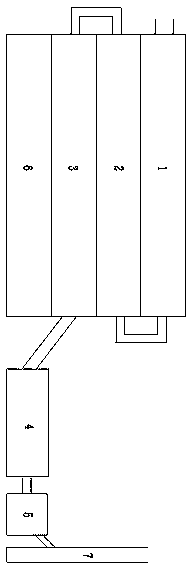

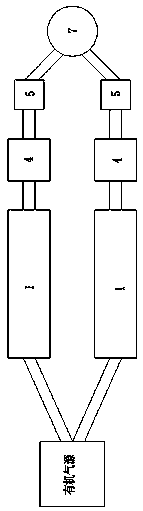

[0032] like Figure 1-Figure 6 As shown, the present invention provides a containerized modular organic gas or flue gas tail gas treatment device, including at least one tail gas treatment device, the outlet of the tail gas treatment device is communicated with the chimney 7; Quenching heat exchange box 1, dust removal, desulfurization and denitrification box 2, and wet electrostatic precipitator and mist removal box 3, the outlet of the wet electrostatic precipitator and mist removal box 3 communicates with a chimney 7.

[0033] Specifically, the dust removal, desulfurization and denitrification box 2 includes a first container and a spray pipe arranged inside the first container, or existing desulfurization and denitrification equipment is installed in the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com