A cold water cooling and nitrogen injection system for buried pipes in gobs

A goaf, cold water technology, applied in mining equipment, earthwork drilling, dust prevention, etc., can solve problems such as oxidation and heating of leftover coal in goaf.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

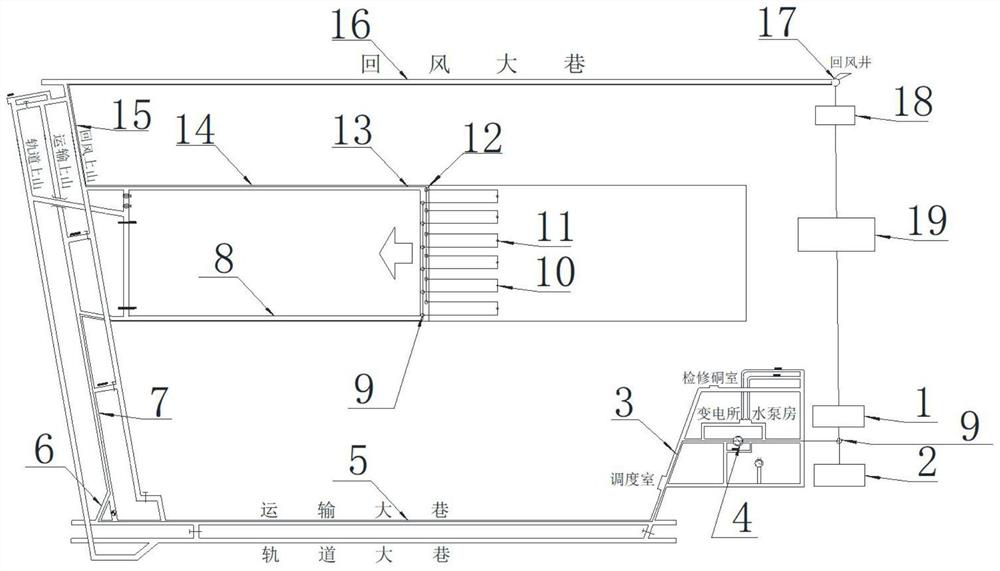

[0024] The hollow arrow on the left side of the number 11 in the figure shows the mining direction of the mining face.

[0025] refer to figure 1 , a gob buried pipe cold water cooling and nitrogen injection system, comprising an industrial chiller 1 and a water inlet pipeline 3, the water inlet pipeline 3 is connected to the industrial chiller 1 through a three-way valve-9, and the three-way The other end of the valve one 9 is connected to the ground nitrogen generator 2, and the water inlet pipeline 3 passes through the auxiliary shaft 4, the mine transportation alley 5, the pedestrian air intake inclined alley 6, the transportation uphill 7 and the section transportation alley 8, And the end of the water inlet pipe 3 is connected with a U-shaped pipeline group 10 through a three-way valve 2. The U-shaped pipeline group 10 is composed of a plurality of U-shaped single pipes connected in series, and a safety valve is arranged inside the U-shaped single pipe. 11, and the retu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com