Moving base plate for machine tool

A base plate and machine tool technology, which is applied to metal processing machinery parts, large fixed members, metal processing equipment, etc., can solve the problems of inability to install machine tools, lack of portability and versatility, and achieve saving manpower and material resources, convenient operation, and use convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

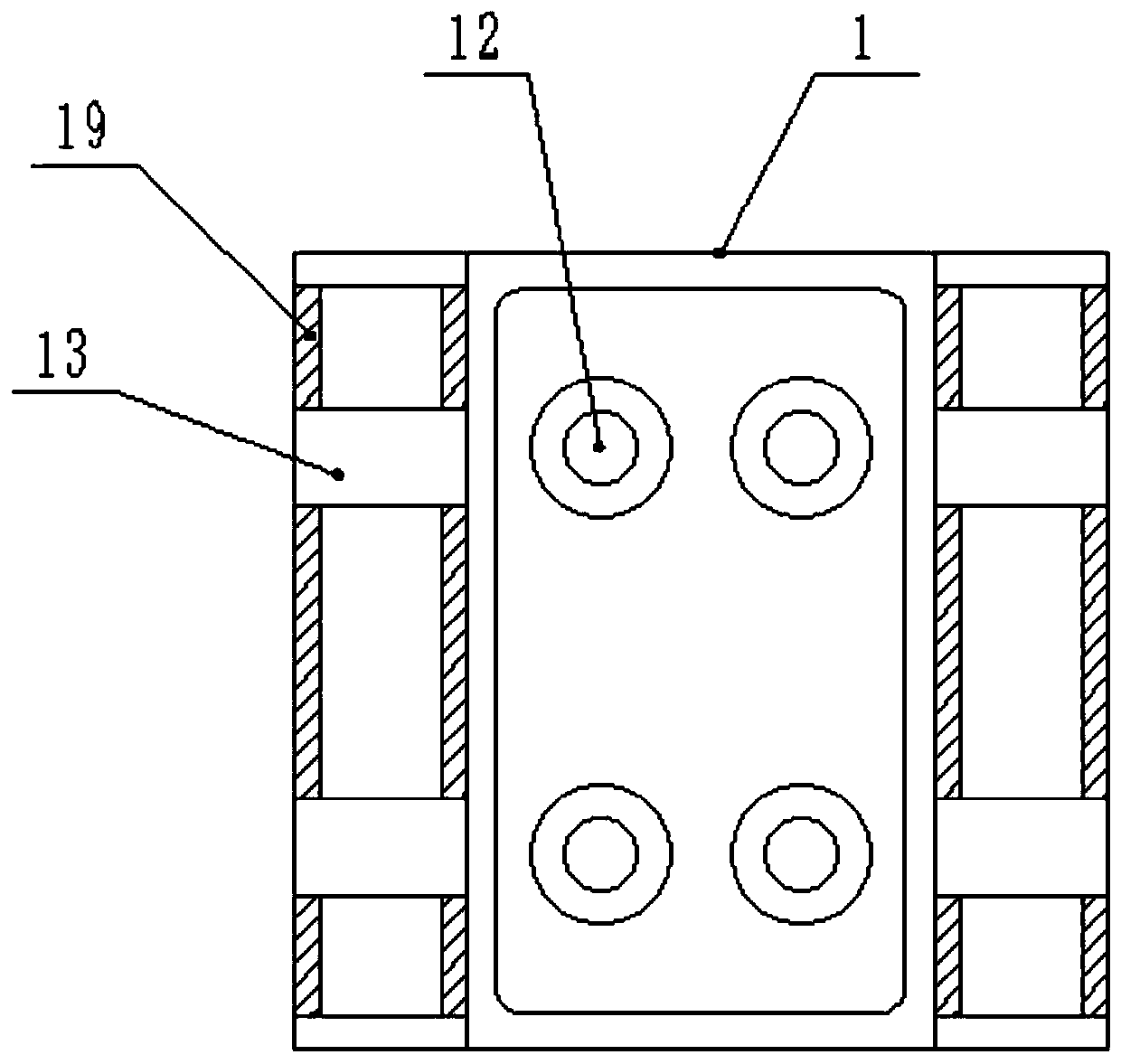

[0016] Such as Figure 1-3 As shown, a mobile base plate of a machine tool includes a support plate 1, a mechanical jack 2, a fine threaded rod 7, a moving wheel 12, a lead screw 15 and an adjustment sleeve 15, and two mechanical jacks 2 are connected by bolts under the support plate 1. Two bottom plates 3 are fixed at the bottom of the two mechanical jacks 2, and the two mechanical jacks 2 have the function of supporting the CNC machine tool. Manually adjusting the length of the mechanical jack 2 can change the height of the CNC machine tool and facilitate adjustment to a suitable position. Above the support plate 1 The fuselage 4 with the CNC machine tool is placed, two telescopic fixed columns 5 are fixed on both sides of the fuselage 4, and the two telescopic fixed columns 5 are respectively welded on the two fixed frames 6, and the two tele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com