A kind of deep-tube deep-drawing die and high-speed deep-drawing process

A technology for deep drawing dies and deep tube parts, which is applied in the direction of forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of quality defects of finished deep tube parts, reduce the possibility of quality defects, smooth metal flow, and Consistent tissue and wall thickness effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] In the field of deep drawing of cylindrical parts, cylindrical parts with a small ratio of diameter to height (not more than 1 / 2) are generally called deep cylindrical parts. In the production of cylindrical parts, the way to speed up the production efficiency of cylindrical parts is usually to increase the deep drawing speed during deep drawing. Compared with some existing methods such as pre-processing materials, the operation is simpler and more effective. However, when drawing thin-walled deep tube parts (with a wall thickness less than 1mm), due to the fast metal flow and severe deformation of the thin-walled part, the use of a high drawing speed can easily lead to wire drawing, Quality defects such as deformation and cracking will affect the use effect, so we need to take some corresponding measures for this problem.

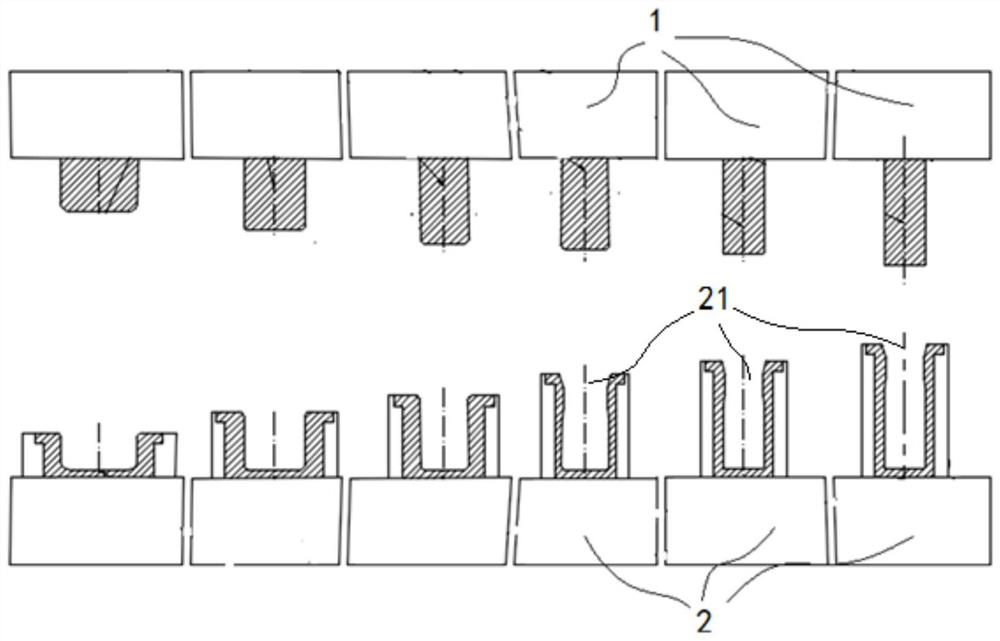

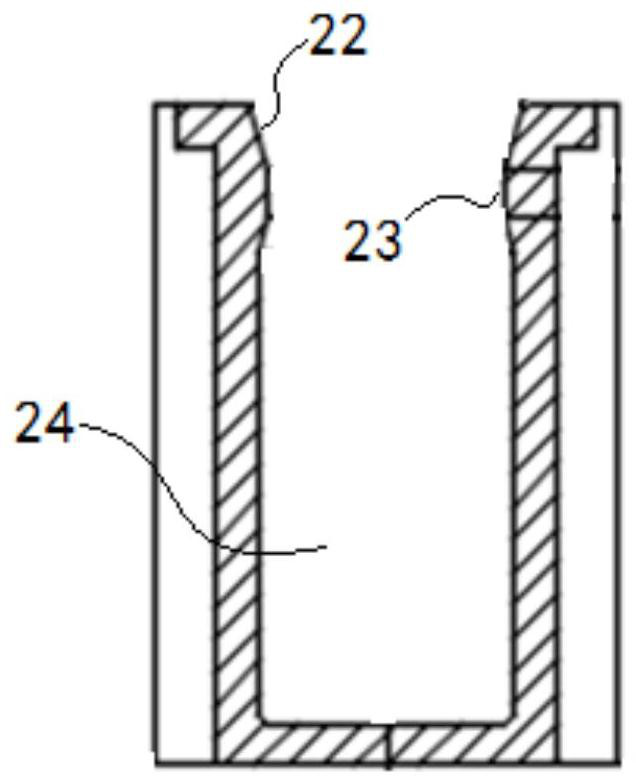

[0033] Such as figure 1 and figure 2 As shown, a deep cylindrical part drawing die is used to reduce the possibility of quality defects in the f...

Embodiment 2

[0035] A high-speed deep-drawing process for deep tube parts, using a deep tube part deep-drawing die in Example 1 for deep-drawing, and the specific size of the deep-tube part for each step needs to be based on the size of the blank and the set size of the finished deep tube part To allocate, it mainly includes the following steps:

[0036] 1. Preliminary forming: prepare the blank, the blank generally chooses a circular blank with a certain thickness, and draws the blank at a deep drawing speed of 220mm / s~300mm / s to form a hollow cylinder with an upper end opening. This stage can be divided into one or more steps according to the size of the blank and the set finished deep tube during actual drawing. Thickness and thinning are not obvious. In order to prevent the deformation of one-time deep drawing from being too severe, it is generally divided into 2 to 4 steps. At this stage, due to the smaller wall thickness reduction and lower drawing height, while adopting a higher dr...

Embodiment 3

[0069] The drawing process of this embodiment is divided into 6 steps. Before drawing, the drawing depth of each pass is allocated according to the size of the original blank and the size of the set finished cylindrical part and the die gap is adjusted, and then the relevant drawing is performed. Under the conditions of the parameters (blankholder force, friction coefficient, deep drawing speed), the circular blank with a diameter of 82mm and a thickness of 0.5mm is thinned to a deep cylinder with a thickness of 0.4mm. Wherein, step 1 uses a conventional deep drawing die for deep drawing.

[0070] 1. Preliminary formation

[0071]Deep drawing step 1: After placing the blank on the lower die, press the blank with the blank holder ring. The blank holder force can be 5000N-20000N, and this embodiment is 8000N. Next, add lubricating fluid at a temperature of 15°C to control the coefficient of friction between the blank and the mold, and finally control the upper die to press down...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com