Multi-cavity composite shear wall and H-shaped steel beam fabricated node and construction method thereof

A technology of combining shear walls and construction methods, applied in the direction of walls, building components, buildings, etc., can solve the problems of easy welding deformation, poor seismic performance, short service cycle, etc., to avoid stress concentration, good seismic performance, and service cycle. long effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

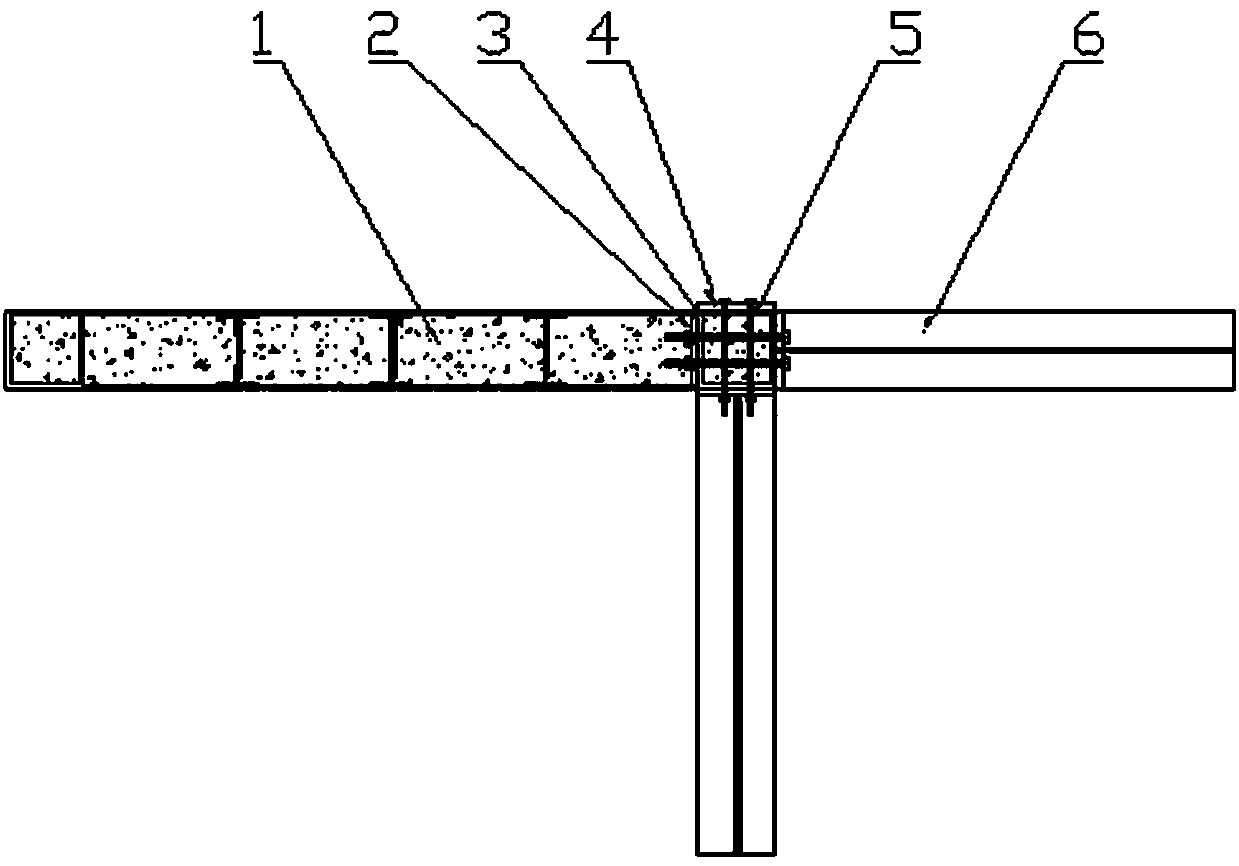

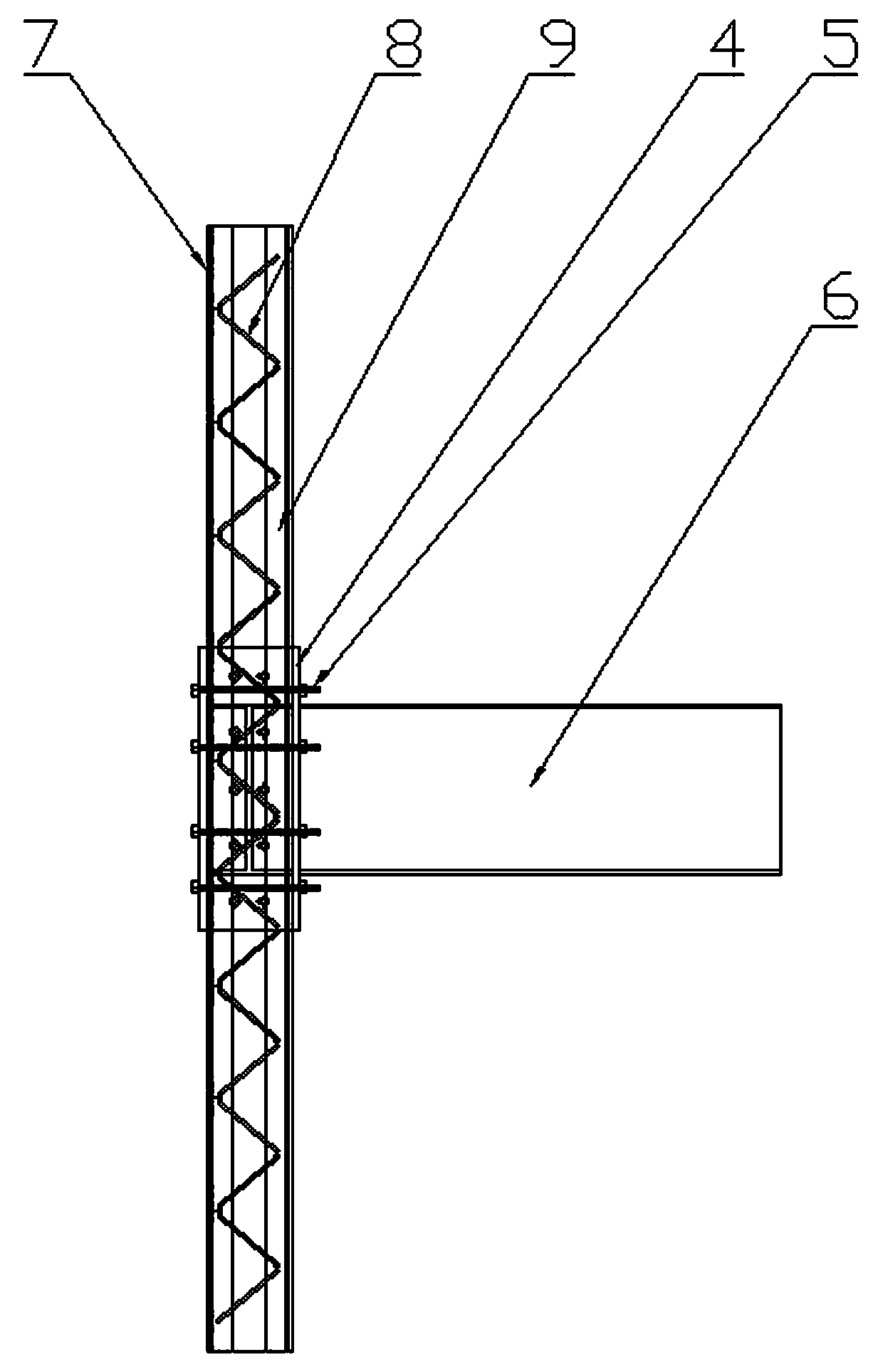

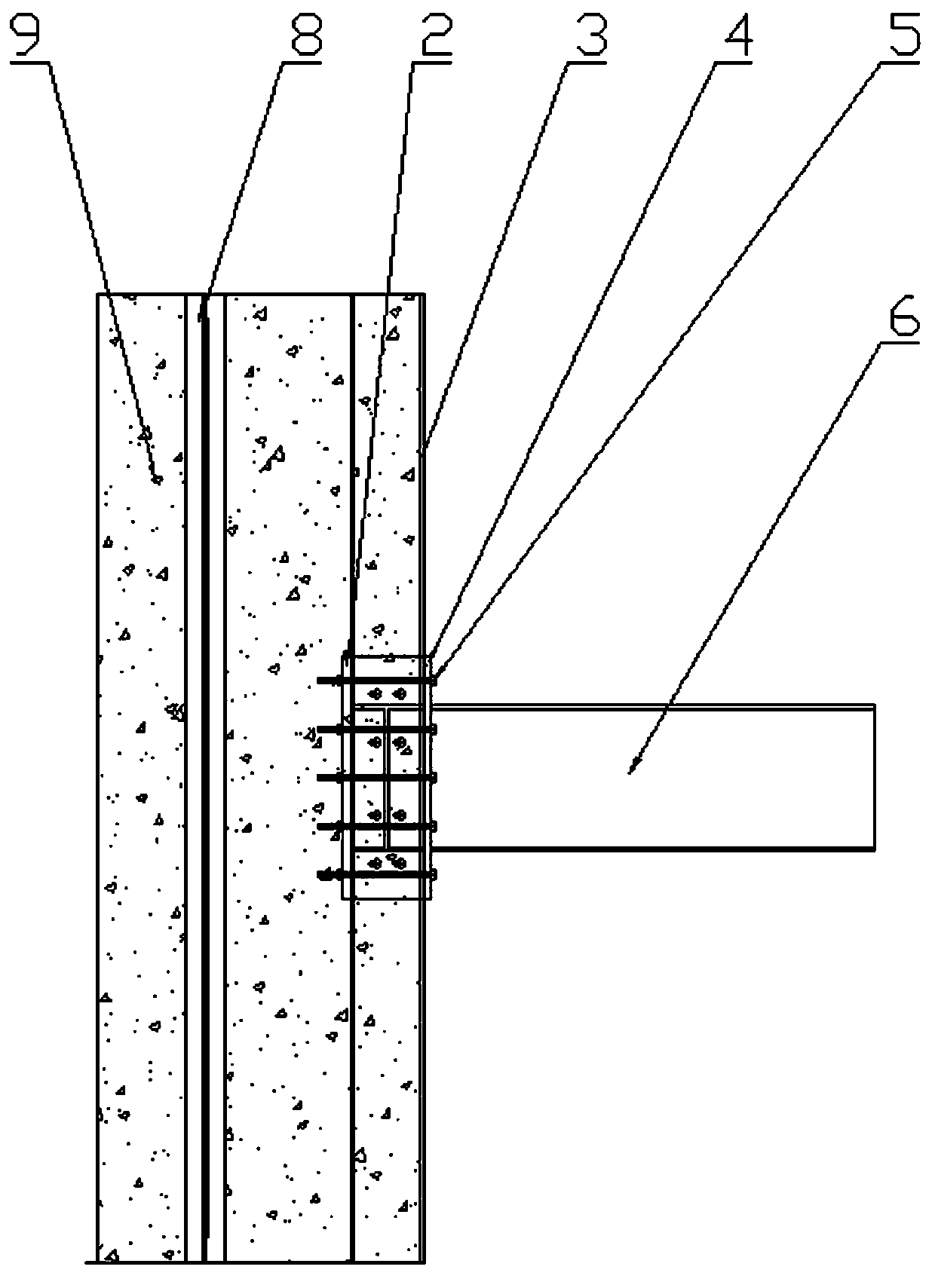

[0029] Example: such as Figure 1-5 As shown, a multi-cavity combined shear wall and H-shaped steel beam assembly type node includes a pair of end columns 3, and the two ends of the end columns 3 are connected with the wall to form a whole. A multi-cavity steel plate composite shear wall 1 is provided between the 3 columns at both ends. The multi-cavity steel plate composite shear wall 1 includes three steel bar trusses 8 distributed at equal intervals. The steel bar trusses 8 include a pair of symmetrically mirrored T-shaped steel 11, between two T-shaped steels 11 is provided with Z-shaped continuous bending steel bar 12 which is welded and fixedly connected with T-shaped steel 11. The upper and lower ends of the steel bar truss 8 are provided with outsourcing steel plates 7 , and concrete 9 is provided between the two outsourcing steel plates 7 . An inner end plate 2 is provided between the end column 3 on one side and the multi-cavity steel plate composite shear wall 1, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com