Manufacturing method of weld defect testing plate for austenitic stainless steel having unfused defects

A technology for austenitic stainless steel and unfused defects, which is applied in the field of manufacturing defect test plates to achieve the effects of simple operation, easy shape and high reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

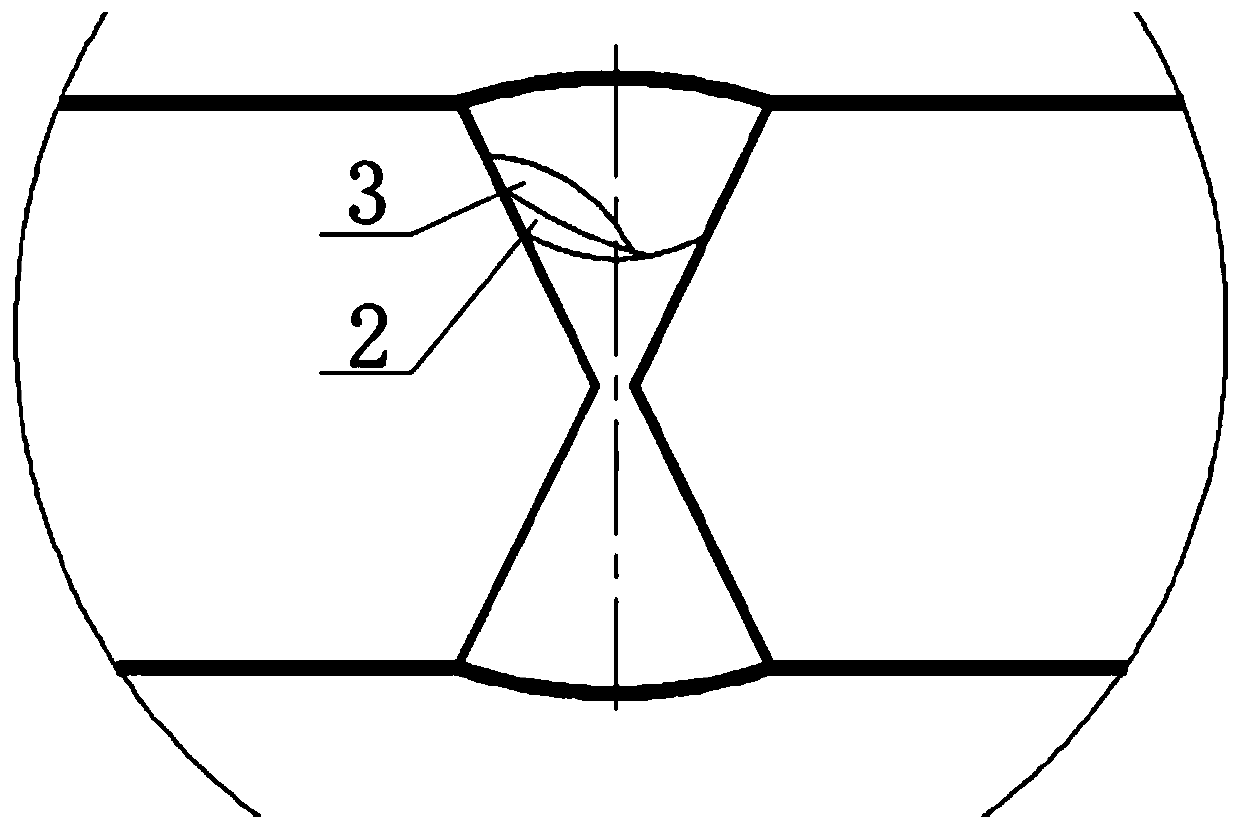

[0055] Manufacturing method of austenitic stainless steel weld defect test plate with unfused defects on the longitudinal groove side, such as Figure 1 to Figure 3 shown, including the following steps:

[0056] (1) Welding blanking: 304L material, thickness 40mm, cutting by CNC plasma, blanking size 500×150×40mm, two pieces of austenitic stainless steel weldment 1 adopt groove machining groove, in order to prevent welding For deformation, symmetrical X-shaped grooves are adopted, and the angle of paired grooves is 40°;

[0057] (2) Preparation before welding: Grinding both sides of the groove to remove oil and debris to ensure the cleanliness of the groove, and spot welding at both ends of the weldment by gas tungsten shielded welding;

[0058] (3) Backing welding: Gas tungsten arc welding is used for root backing welding, and the welding wire is ER317L (mod.) from Bo-Le, with a diameter of 2.4mm, which is a fully austenitic welding wire. The back side is protected by argon...

Embodiment 2

[0063] Method for manufacturing austenitic stainless steel weld defect test plate with transverse non-fusion defects, such as Figure 4 to Figure 6 shown, including the following steps:

[0064] (1) Welding blanking: 304L material, thickness 40mm, cutting by CNC plasma, blanking size 500×150×40mm, two pieces of austenitic stainless steel weldment 1 adopt groove machining groove, in order to prevent welding For deformation, symmetrical X-shaped grooves are adopted, and the paired groove angle is 40°;

[0065] (2) Preparation before welding: Grinding both sides of the groove to remove oil and debris to ensure the cleanliness of the groove, and spot welding at both ends of the weldment by gas tungsten shielded welding;

[0066] (3) Backing welding: Gas tungsten arc welding is used for root backing welding, and the welding wire is ER317L (mod.) from Bo-Le, with a diameter of 2.4mm, which is a fully austenitic welding wire. The back side is protected by argon gas, and the front a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com