Flexible clamping device for single-point incremental forming of sheet metal and forming method

A single-point progressive, flexible clamping technology, applied in the direction of feeding device, positioning device, storage device, etc., can solve the problems of poor interchangeability of forming tooling, waste of resources, idle or discarded, etc., to improve processing accuracy, The effect of avoiding mutual interference and saving production time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments. This embodiment is carried out on the premise of the technical solution of the present invention, and detailed implementation and specific operation process are given, but the protection scope of the present invention is not limited to the following embodiments.

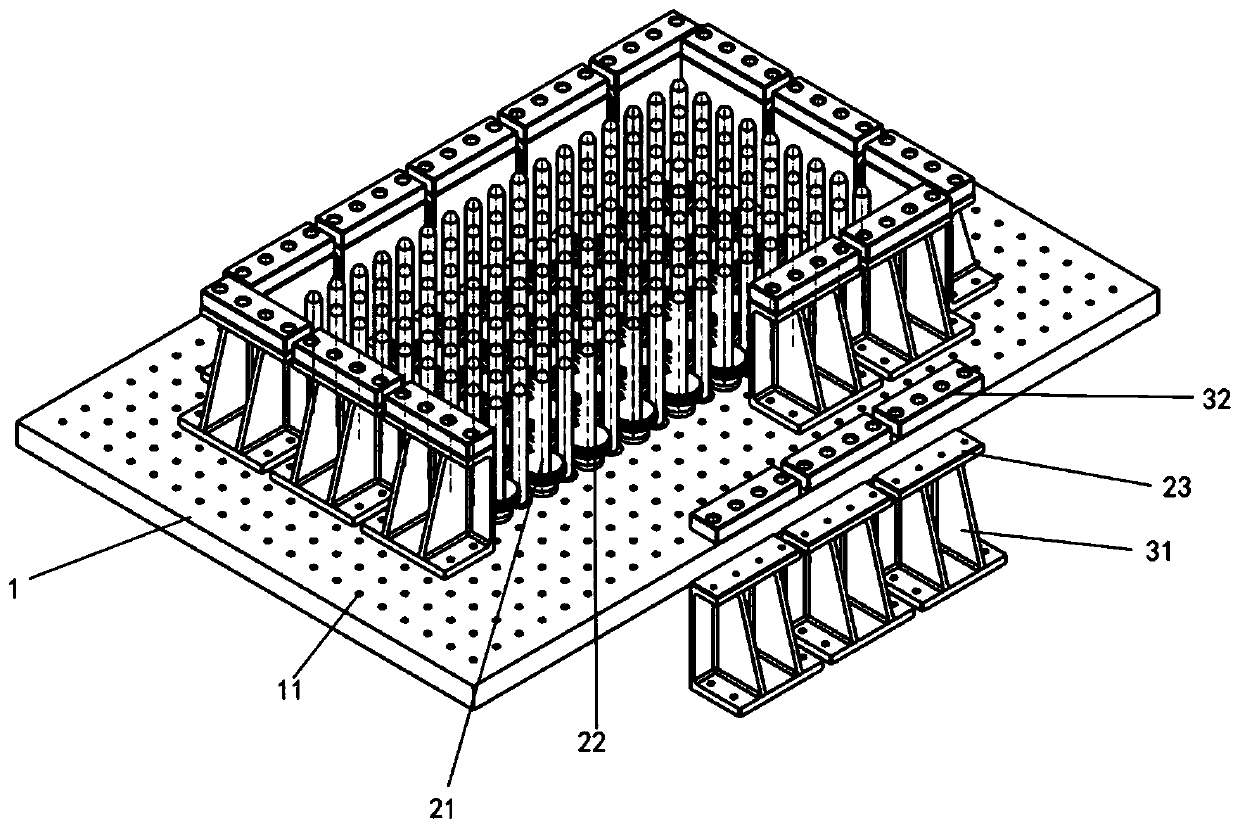

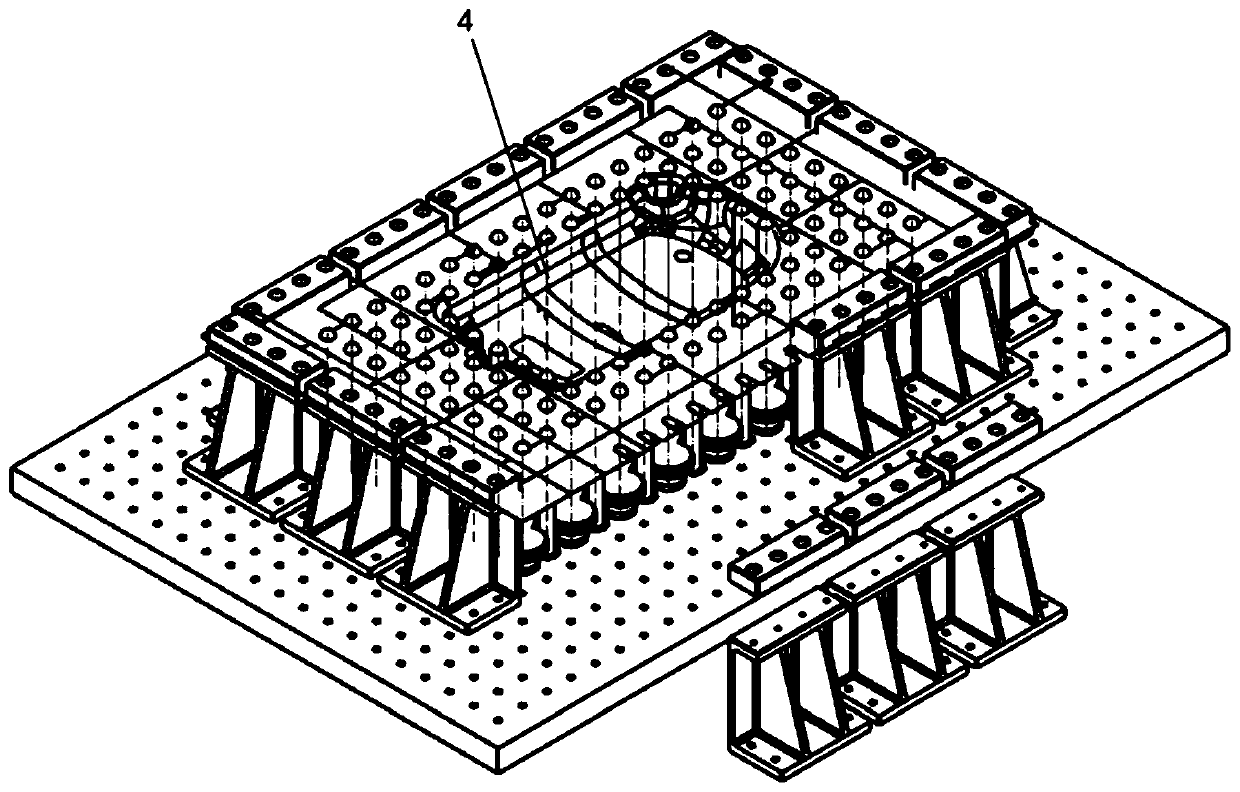

[0034] Such as figure 1 and figure 2 As shown, this embodiment provides a flexible clamping device for single-point incremental forming of sheet metal, including a base plate 1, a plurality of clamping modules and a plurality of adjustable support modules, the clamping modules and adjustable support modules are both It is detachably connected with the bottom plate 1. in:

[0035] The bottom plate 1 is provided with mounting holes 11 arranged in a matrix. The thickness of the bottom plate 1 is generally 40-50 mm. The pitch of the mounting holes 11 arranged in an array is a multip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com