Screw delivery rack for electric drill

An electric drill and screw technology, applied in the field of screw conveying device, can solve the problems of small scope of application, easy loss and crooked screws, high cost of electric drive, and achieve the effects of changing the heavy and heavy carrying, broad market prospect and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solutions of the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the embodiments of the present invention.

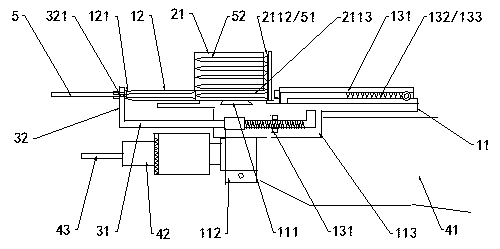

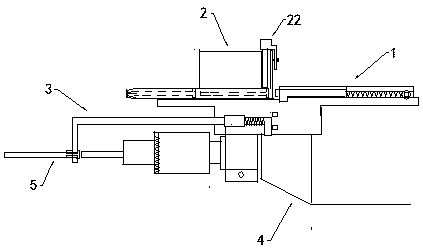

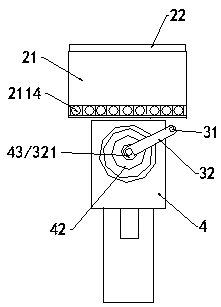

[0028] As shown in the figure, the electric drill screw delivery rack includes a nail pushing mechanism 1 , a nail removing mechanism 2 , and a nail turning mechanism 3 .

[0029] 1. Push nail mechanism.

[0030] Such as Figure 1 to Figure 6 As shown, the push nail mechanism includes a frame plate 11, a through pipe 12, and a push bolt 13. The frame plate 11 is placed flat on the hand-held electric drill 4, and the clip 112 on the bottom surface is enclosed and fixed with the front end of the electric drill body 41. The front end of the frame plate is installed through a Pipe 12 is used to transmit the screw 5, and the middle is a deck 111, which is used for positioning and placing the nail box 21 that can move to both sides. The rear end is equipped with a push bolt 13, which is us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com