Chicken and duck feed

A technology for feed, chickens and ducks, applied in the field of breeding, can solve the problems of poor health, insufficient nutrition of chickens and ducks, and high breeding costs, and achieve the effects of increasing oxidation stability, reducing feed efficiency and being easy to degrade.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

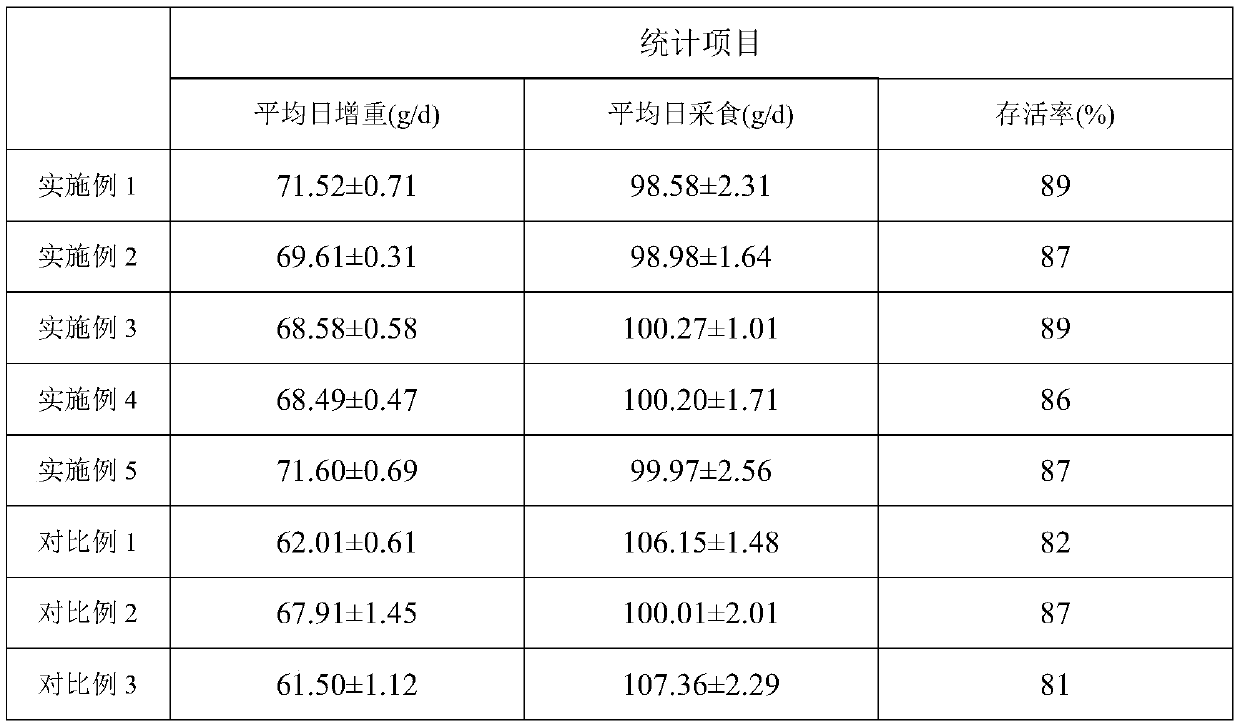

Examples

Embodiment 1

[0019] Preparation of chicken and duck feed: 40 parts of crushed corn kernels, 2 parts of soybean meal, and 27 parts of corn silage are mixed and ground to pass through a 300-mesh sieve, and inoculated with Bacillus for fermentation. The fermentation process is that Bacillus is activated with brown sugar water, and the water temperature is 30°C , the activated bacillus activation solution is evenly sprayed on the mixture, sealed, and fermented for 3 days to obtain the fermented material; 8 parts of spirulina, 1 part of Paraguayan holly extract, 2 parts of mineral supplement, sodium bicarbonate 0.6 parts, 0.04 parts of monensin, 0.7 parts of food grade kaolin, and 0.6 parts of additives are mixed evenly with the fermentation material, homogenized at 65°C for 15 minutes, then dehydrated, processed and granulated at 85°C. The chicken and duck feed finished product with a particle size of 2 mm is obtained.

Embodiment 2

[0021] Preparation of chicken and duck feed: Mix and grind 45 parts of crushed corn kernels, 2 parts of soybean meal, and 25 parts of corn silage to pass through a 300-mesh sieve, inoculate Bacillus for fermentation. The fermentation process is that Bacillus is activated with brown sugar water, and the water temperature is 30°C , the activated bacillus activation solution is evenly sprayed on the mixture, sealed, and fermented for 3 days to obtain the fermented material; 8 parts of spirulina, 0.5 part of Paraguayan holly extract, 3 parts of mineral supplement, sodium bicarbonate Mix 1 part, 0.04 part of monensin, 1 part of food grade kaolin, and 1 part of additives with the fermentation material, homogenize at 65°C for 15 minutes, then dehydrate, process and granulate at 85°C. The chicken and duck feed finished product with a particle size of 2 mm is obtained.

Embodiment 3

[0023] Preparation of chicken and duck feed: 50 parts of crushed corn kernels, 3 parts of soybean meal, and 30 parts of corn silage are mixed and ground to pass through a 300-mesh sieve, and inoculated with Bacillus for fermentation. The fermentation process is that Bacillus is activated with brown sugar water, and the water temperature is 30°C , the activated bacillus activation solution is evenly sprayed on the mixture, sealed, and fermented for 3 days to obtain the fermented material; 6 parts of spirulina, 0.5 part of Paraguayan holly extract, 1 part of mineral supplement, sodium bicarbonate 0.9 parts, 0.05 parts of monensin, 0.5 parts of food grade kaolin, and 0.8 parts of additives are mixed evenly with the fermentation material, homogenized at 65°C for 15 minutes, then dehydrated, processed and granulated at 85°C. The chicken and duck feed finished product with a particle size of 2 mm is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com