Water-cooled light-concentrating optical fiber probe used for stable section of hypersonic-speed low-density wind tunnel

An optical fiber probe and hypersonic technology, which is applied in the testing, measuring devices, instruments, etc. of machine/structural components, etc., can solve the problems of easy burning of the optical fiber probe, inability to meet the measurement requirements, and low light collection efficiency of the optical fiber probe. , to achieve the effect of improving light collection efficiency, simple structure and strong reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

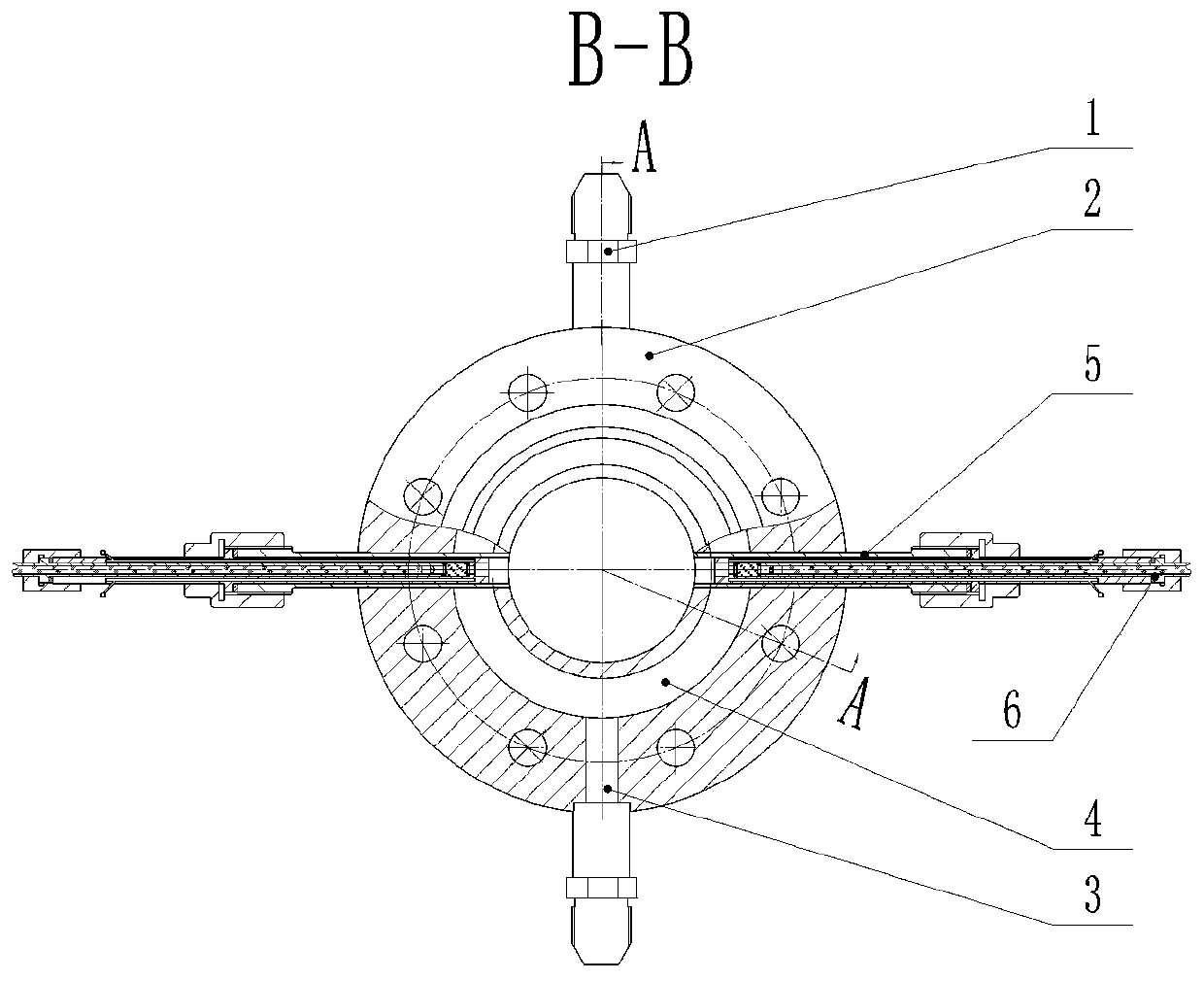

[0028] In this embodiment, the water-cooled concentrating optical fiber probe used in the stable section of a hypersonic low-density wind tunnel of the present invention is installed on a water-cooled test flange.

[0029] Such as image 3 As shown, the water-cooling test flange includes a water-cooling joint 1, a flange 2, a straight water channel 3, an annular water channel 4 and a test joint 5;

[0030] The flange 2 is a circular ring, and the cavity in the center of the circular ring is used to pass through the hypersonic low-density wind tunnel airflow. In the ring wall of the circular ring, an annular water channel 4 is arranged, and a uniform channel is opened on the annular water channel 4. Two straight waterways 3 perpendicular to the annular waterway 4 are arranged, and the straight waterway 3 is connected with a water-cooling joint 1, one water-cooling joint 1 is externally connected to the cooling water inlet pipe, and the other water-cooling joint 1 is externally ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com