Bind pipe for municipal greening and manufacturing method thereof

A manufacturing method and blind pipe technology, which can be used in applications, soil drainage, construction, etc., can solve the problems of high cost, single structure, and complicated manufacturing, and achieve the effects of fast drainage, simple manufacturing and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

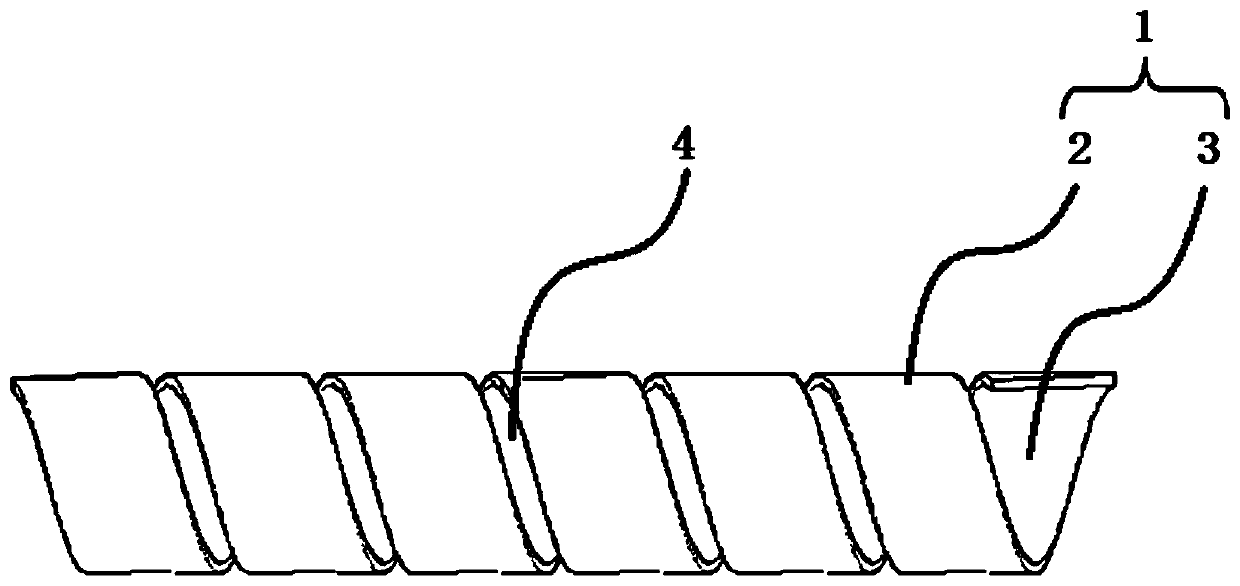

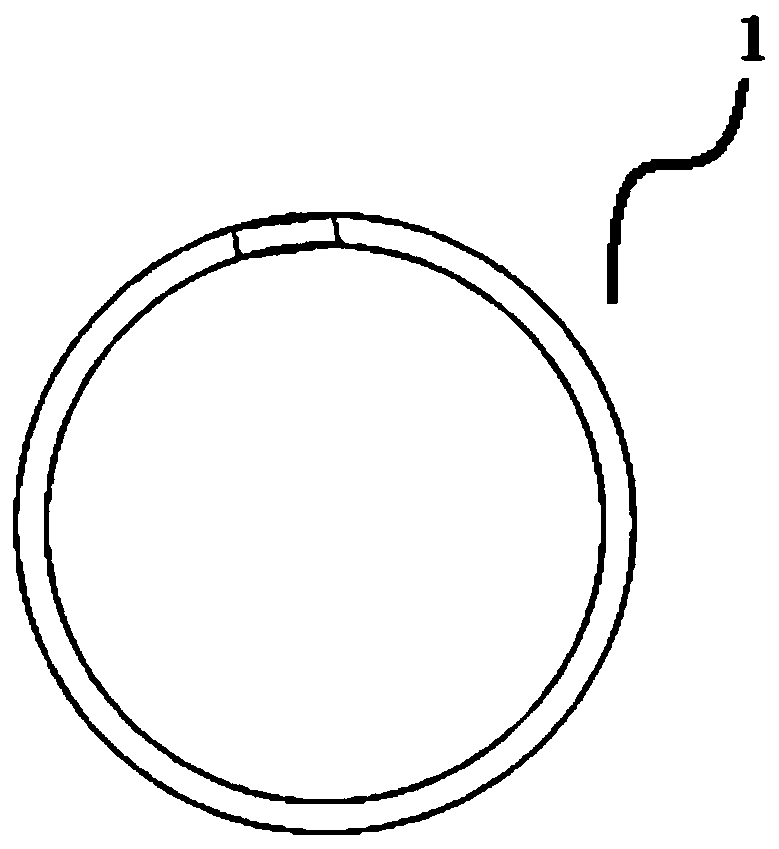

[0029] Such as Figure 1-2 As shown, a blind pipe for municipal greening includes a pipe body 1, the pipe body 1 includes an annular pipe wall 2, and an inner chamber 3 surrounded by the pipe wall 2, the pipe body 1 is provided with a water seepage port 4, and the water seepage port 4 communicates with the inner cavity 3, and the water seepage port 4 extends continuously and spirally along the length direction of the pipe body 1.

[0030] The blind pipe manufacturing method: use a spiral plastic extruder, place a corresponding extrusion mold, the extrusion mold is provided with a spiral inner cavity, add pvc raw materials, preheat, start production, and extrude a pipe body with a spiral water seepage , intercept the predetermined length according to the need, and store it.

[0031] In this embodiment, the water seepage port 4 can further increase the deformability of the pipe body 1, and the pipe body 1 can be compressed or elongated to change the size of the water seepage po...

Embodiment 2

[0033] Such as Figure 3-4 As shown, a blind pipe for municipal greening includes a pipe body 1, the pipe body 1 includes an annular pipe wall 2, and an inner cavity 3 surrounded by the pipe wall 2, and the pipe body 1 is provided with a water seepage port 4, The water seepage port 4 communicates with the inner cavity 3 , and the water seepage port 4 extends continuously and linearly along the length direction of the pipe body 1 .

[0034] The manufacturing method of the blind pipe: use a spiral plastic extruder, place a corresponding extrusion mold, the extrusion mold is provided with a c-shaped opening, add pvc raw materials, preheat, start production, and the length direction of the extruded pipe body is straight Extend water seepage port 4, intercept predetermined length as required, store.

Embodiment 3

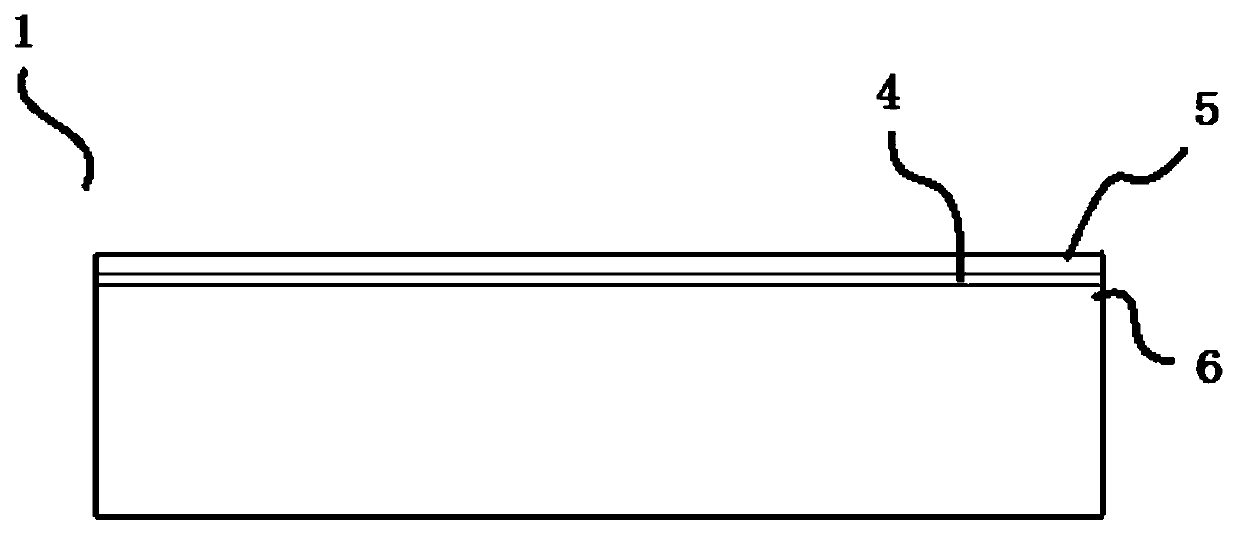

[0036] Such as Figure 5-6 As shown, a blind pipe for municipal greening includes a pipe body 1, the pipe body 1 includes an annular pipe wall 2, and an inner cavity 3 surrounded by the pipe wall 2, and the pipe wall 2 includes two sides located in its length direction , that is, the first side 5 and the second side 6, the first side 5 and the second side 6 are not connected, the gap between the two is the water seepage port 4, and the water seepage port 4 and the pipe wall 2 are located on the same plane, The water seepage port 4 extends continuously and linearly along the length direction of the pipe body 1 . The water seepage port 4 communicates with the inner cavity 3 .

[0037] The manufacturing method of the blind pipe adopts a spiral plastic extruder, and places a corresponding extrusion mold. The extrusion mold is provided with partially overlapping openings, and pvc raw materials are added, preheated, and the production is started. The first part of the extruded pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com