On-line production line for producing water absorption core bodies of sanitation supplies

A hygienic product and water-absorbing core technology, which is applied in the field of hygienic product production, can solve problems such as uneven distribution and waste of polymer water-absorbing materials, and achieve the effects of uniform distribution, good fusion effect, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Specific embodiments of the present invention will be described below with reference to the accompanying drawings.

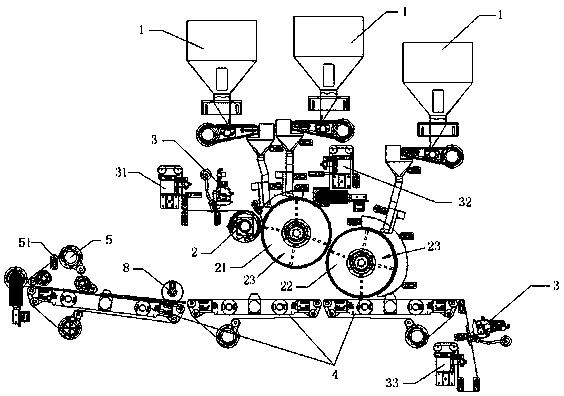

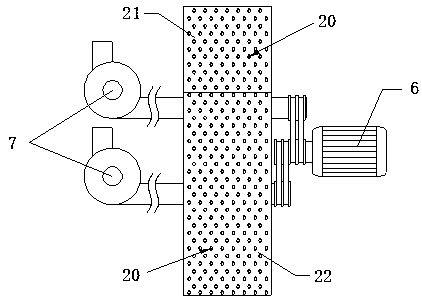

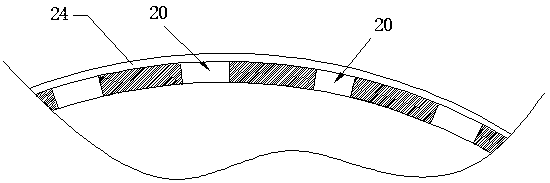

[0013] refer to Figure 1 to Figure 3 , an on-line production line of water-absorbing cores for sanitary products, comprising a water-absorbing material blanking mechanism 1, a glue spraying device 3, a coating layer conveying mechanism, a transfer wheel device and a transfer device 4, the transfer wheel device including a motor 6, a suction fan 7, Left transfer wheel 21 and right transfer wheel 22, the diameter of left transfer wheel 21 and right transfer wheel 22 is identical, and motor 6 transmission connects left transfer wheel 21 and right transfer wheel 22 synchronously and direction rotates oppositely, left transfer wheel 21 and right transfer wheel The rotating speeds of 22 are the same, preferably the left transfer wheel 21 rotates in the counterclockwise direction, and the right transfer wheel 22 rotates in the clockwise direction. The peripher...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com