Food processor with good denoising effect

A food processing machine and noise reduction technology, which is applied in home appliances, applications, kitchen utensils, etc., can solve the problems of limited opening size of the feeding channel of the cup lid, complex structure of the feeding lid assembly, and inconvenient cleaning and use, so as to increase the contact probability , Improve the rate of good products, improve the effect of crushing rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

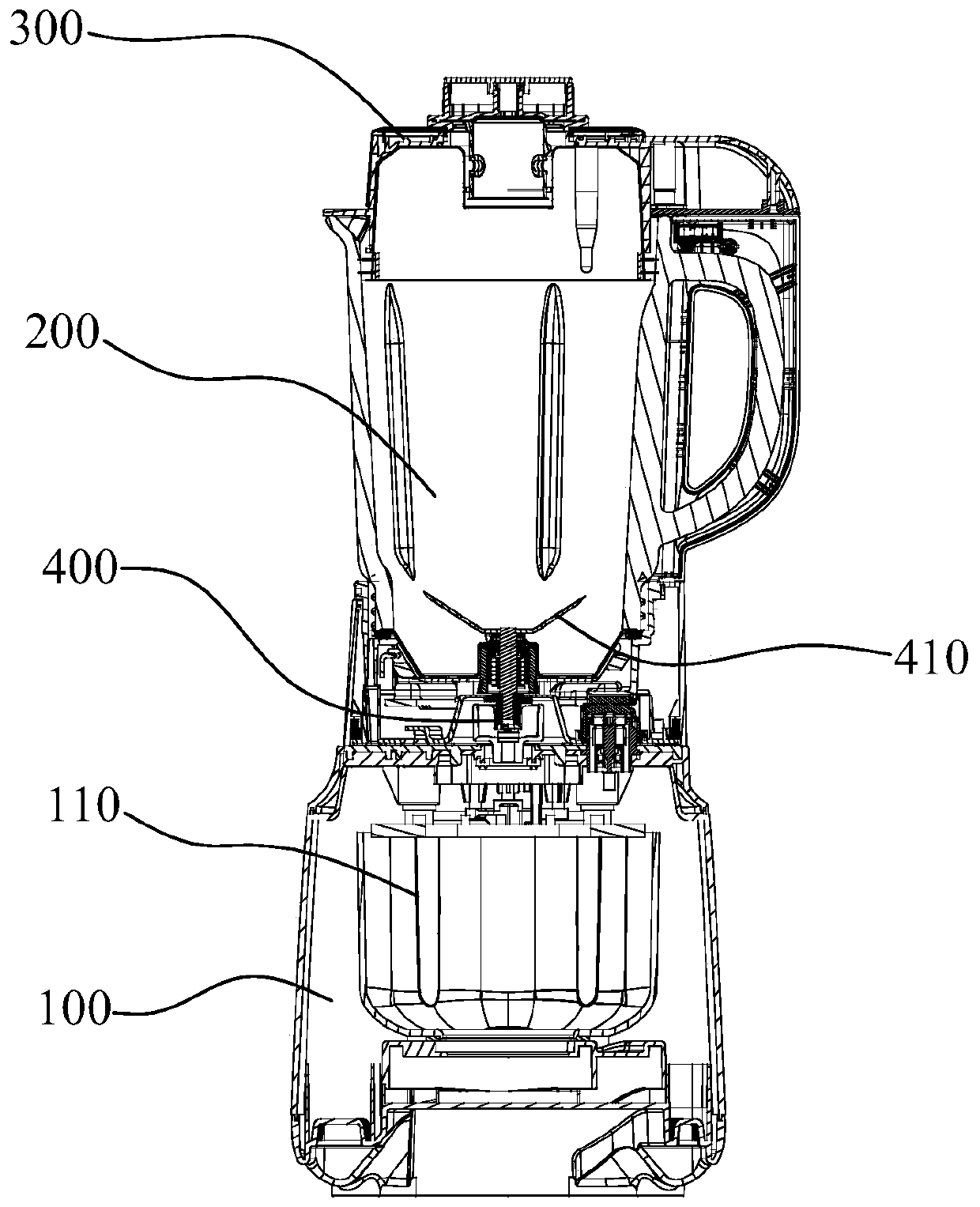

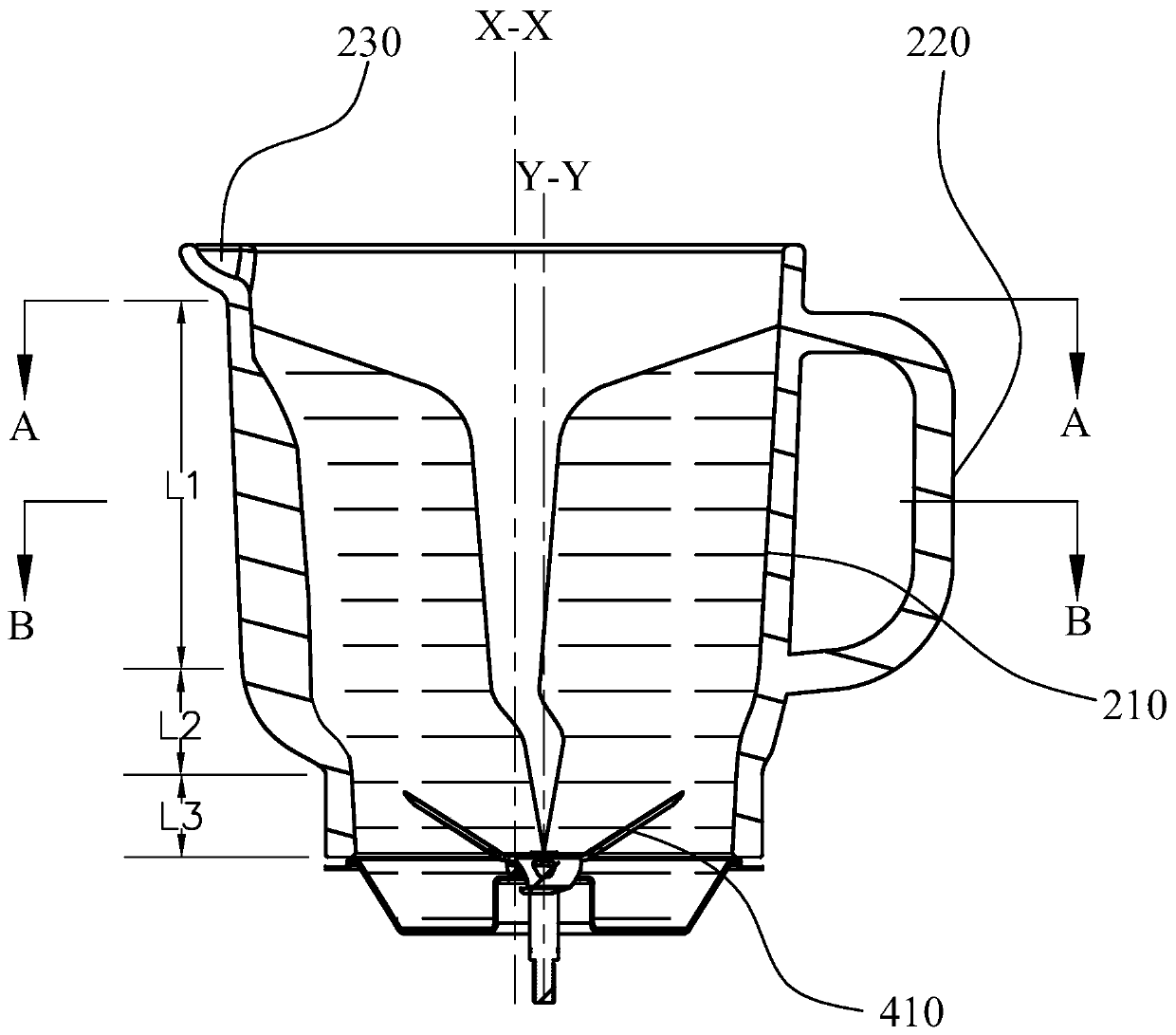

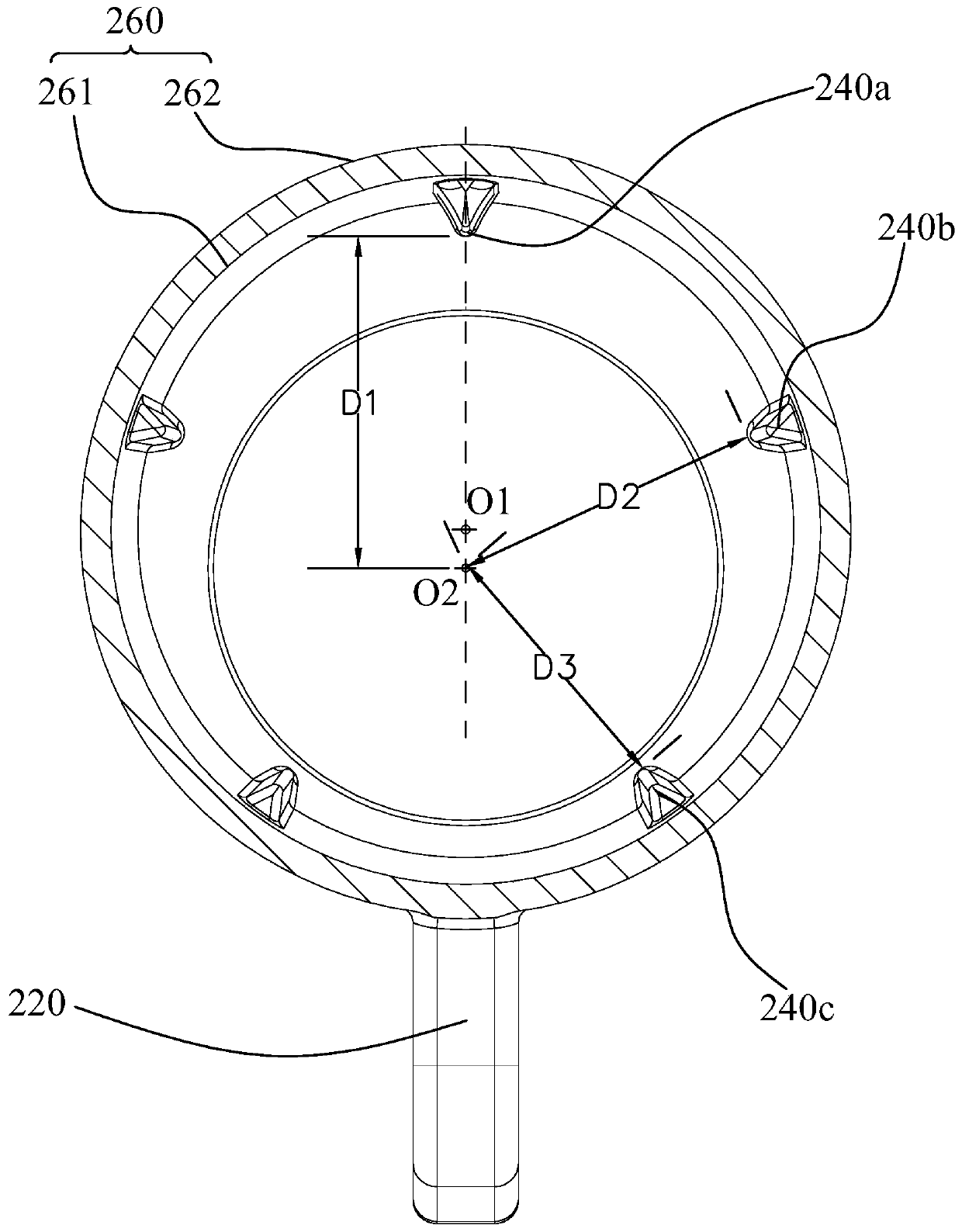

[0042] This embodiment provides a food processor with good noise reduction effect, such as Figure 1-5As shown, it includes a base 100, a cup body 200 and a cup cover 300. The base 100 is provided with a motor 110, the cup body 200 is arranged on the base 100, and the cup cover 300 is closed on the mouth of the cup body 200. The bottom of the cup body 200 is provided with a cutter head assembly 400, and the cutter head assembly 400 includes a crushing knife 410 located at the inner bottom of the cup body 200, and the crushing knife 410 rotates under the drive of the motor 110 to crush the particles in the cup body 200. Ingredients. The cup body 200 includes a cup wall 210, a handle 220, and a spout 230. The inside of the cup wall 210 is provided with at least two diversion ribs 240 integrally formed with the cup body 200. In this embodiment, the cup body The inner wall of the cup is provided with a structural scheme of five guide ribs 240 , the water spout 230 is provided at ...

Embodiment 2

[0053] to combine Figures 6 to 9 As shown, the difference between this embodiment and Embodiment 1 is that: the diversion rib 240 includes a deflector rib 241, a first diversion rib 242 and a second diversion rib 243, and the central axis of the upper part L1 of the cup is connected to the lower part The eccentric plane defined by the central axis of L3 runs through the deflector rib 241 , and the radial width S1 of the deflector rib 241 is greater than the radial width of other deflector ribs. Specifically, in this embodiment, S1>S2 and S1>S3. Preferably, there is one diversion rib, and the first and second diversion ribs 242 are two respectively. The eccentric plane defined by the central axis is symmetrical.

[0054] Such as Figure 9 As shown, by setting the deflector ribs, the rotating slurry can be strengthened to disturb the flow, destroying the original regular rotation of the slurry close to the inner wall, and the flow direction of the slurry is turned to form an...

Embodiment 3

[0063] Such as Figure 10 As shown, the difference between this embodiment and Embodiment 1 or 2 is that the handle 220 includes a first extension 221 extending laterally from the outer wall of the cup body, a second extension 223 and a handshake 222, and the handshake is connected to the The first extension part 221 and the second extension part 223, the first extension part 221 forms the upper end of the handle and is connected with the upper part L1 of the cup, the second extension part 223 forms the lower end of the handle, and the handshake part 222 is from The upward and downward direction is inclined to the side away from the cup body and forms an angle α, so that the center of gravity of the cup body moves downward as a whole, which is convenient for the user to pick and place. Preferably, the angle α ranges from 3 to 15 degrees.

[0064] Further, the lower end of the handle is at least partially connected to the eccentric transition portion L2. Optionally, the lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com