Cam roller type walnut horizontal-squeezing shell-breaking system

A horizontal extrusion, roller type technology, applied in the field of cam roller type walnut horizontal extrusion shell breaking system, can solve the problems of high unit energy consumption, efficiency impact, poor economy, etc., to improve the shell breaking rate and improve transportation. rate, avoid the effect of leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] Attached below Figure 1-Figure 15 The walnut pre-shell breaking system disclosed in this embodiment is further described:

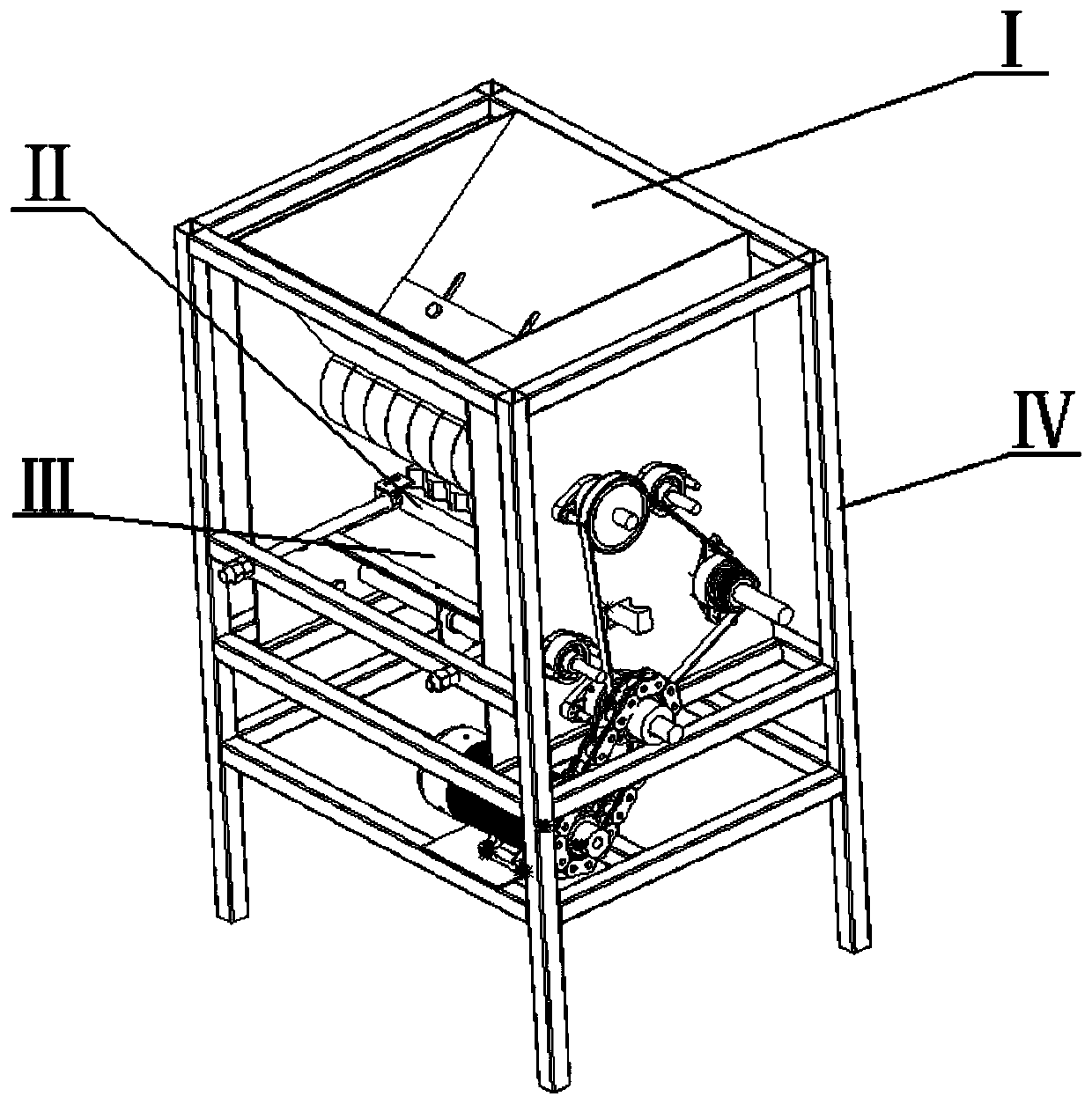

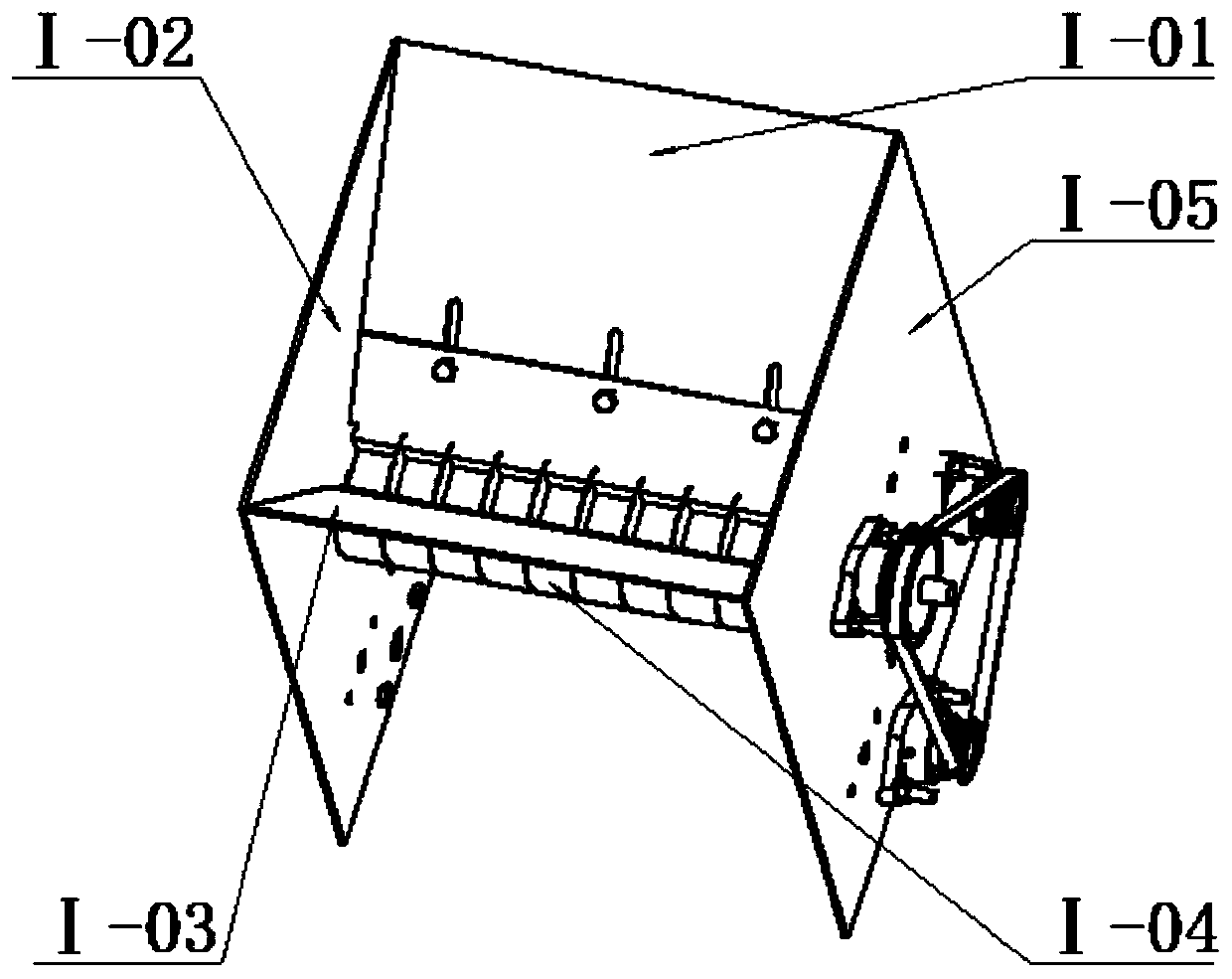

[0068] Refer to attached figure 1 As shown, the cam roller walnut horizontal extrusion system consists of four parts: feeding device I, shell breaking device II, blanking device III and frame IV. The feeding device I is set above the shell breaking device II, and the shell breaking device Below the II, a blanking device III is arranged. The feeding device I includes a feeding box, and the feeding box includes the left panel I-02 of the chassis, the right panel I-05 of the chassis, the adjustable feeding scraper mechanism I-01 in the feeding device I, and the feeding baffle I -03 is connected with the left side panel I-02 and the right side panel I-05 of the chassis by welding, and the feeding baffle I-03 and the adjustable feeding scraper mechanism I-01 are distributed at a set angle.

[0069] The intermittent feeding roller Ⅰ-04 passes through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com