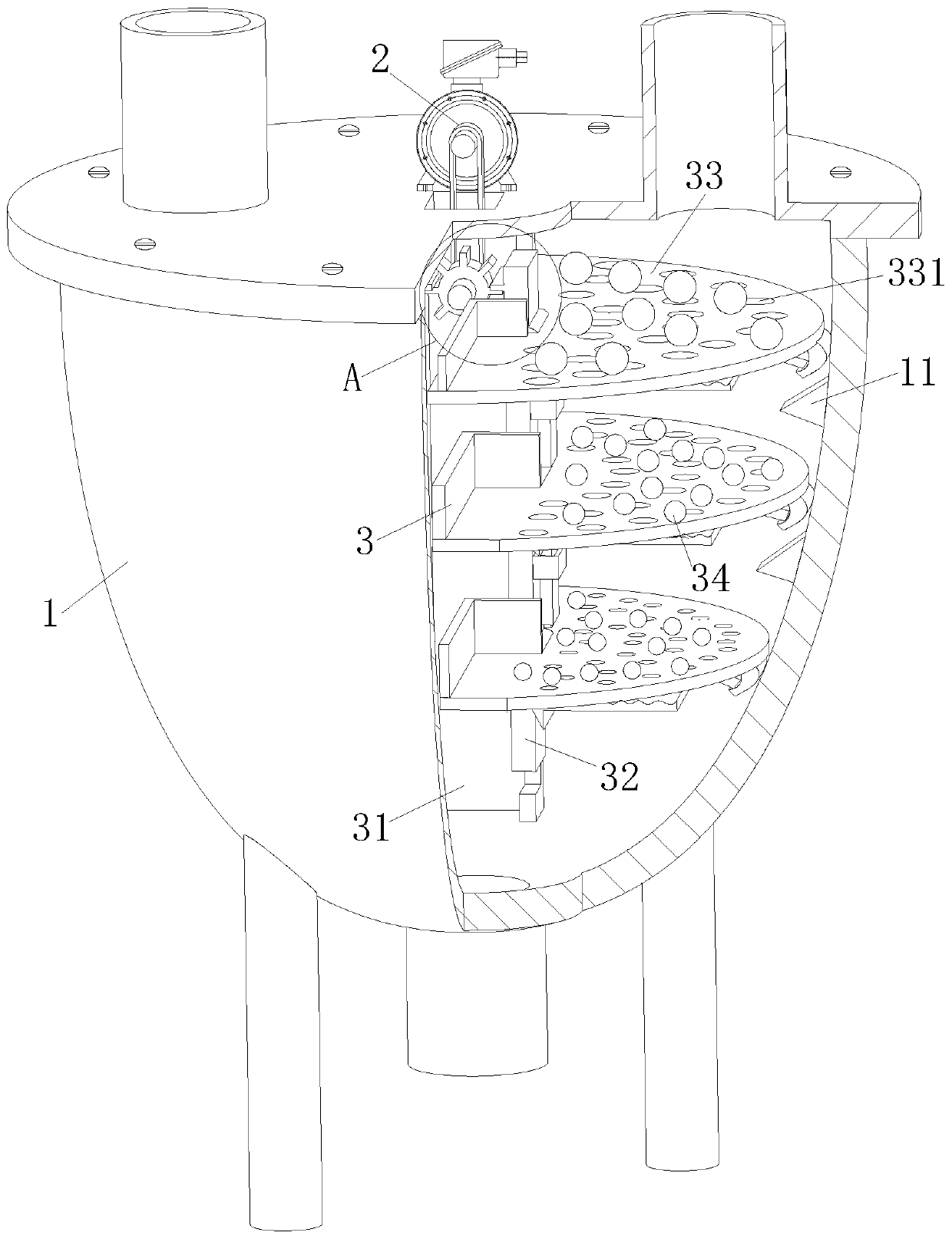

Distiller's grains treatment device for production of baijiu

A processing device and technology of distiller's grains, which is applied in the field of distiller's grains processing devices for liquor production, can solve problems such as increasing liquor processing costs, polluting the ecological environment, and wasting resources, so as to improve the crushing effect and efficiency, reduce time costs, and reduce disassembly The effect of cleaning frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

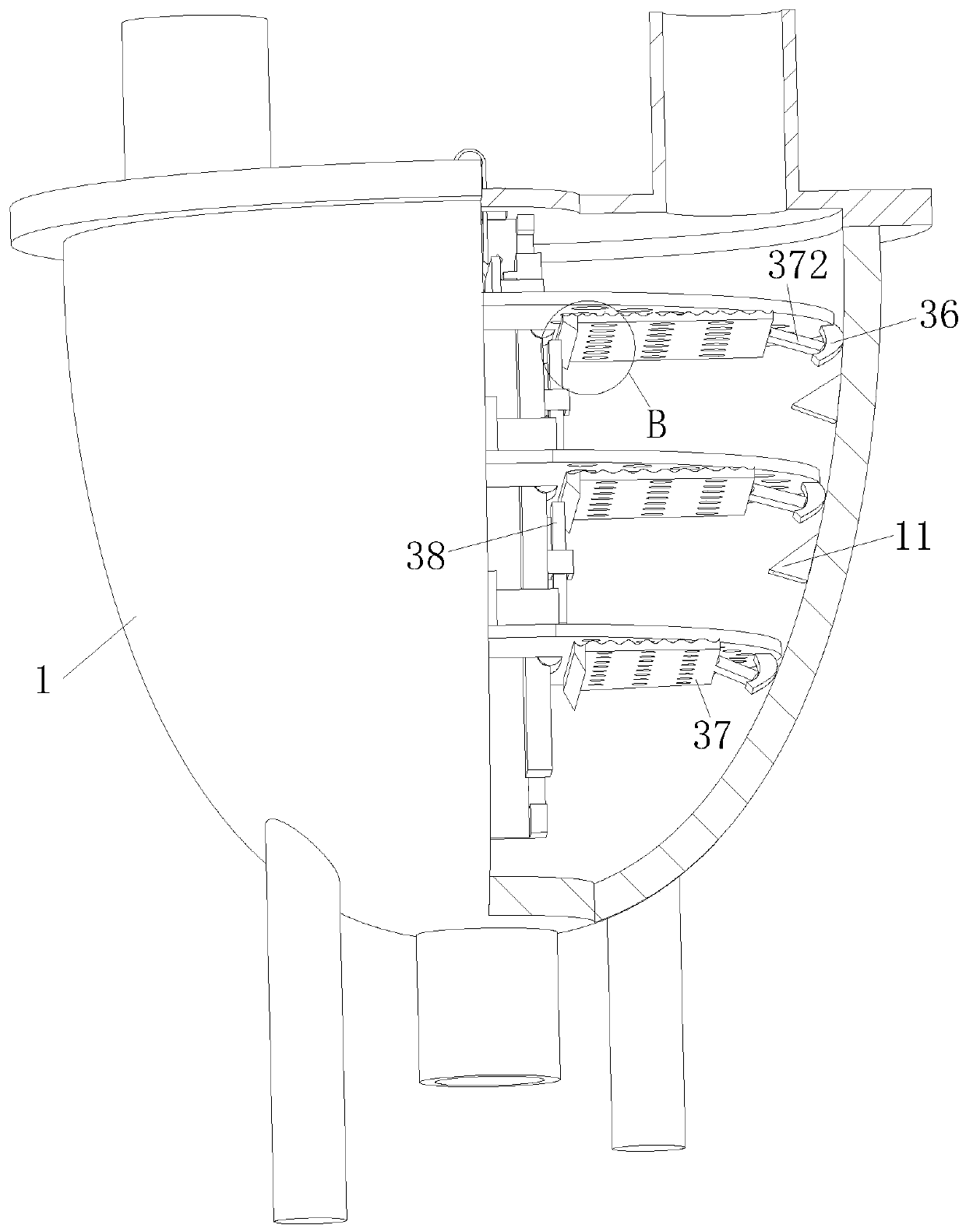

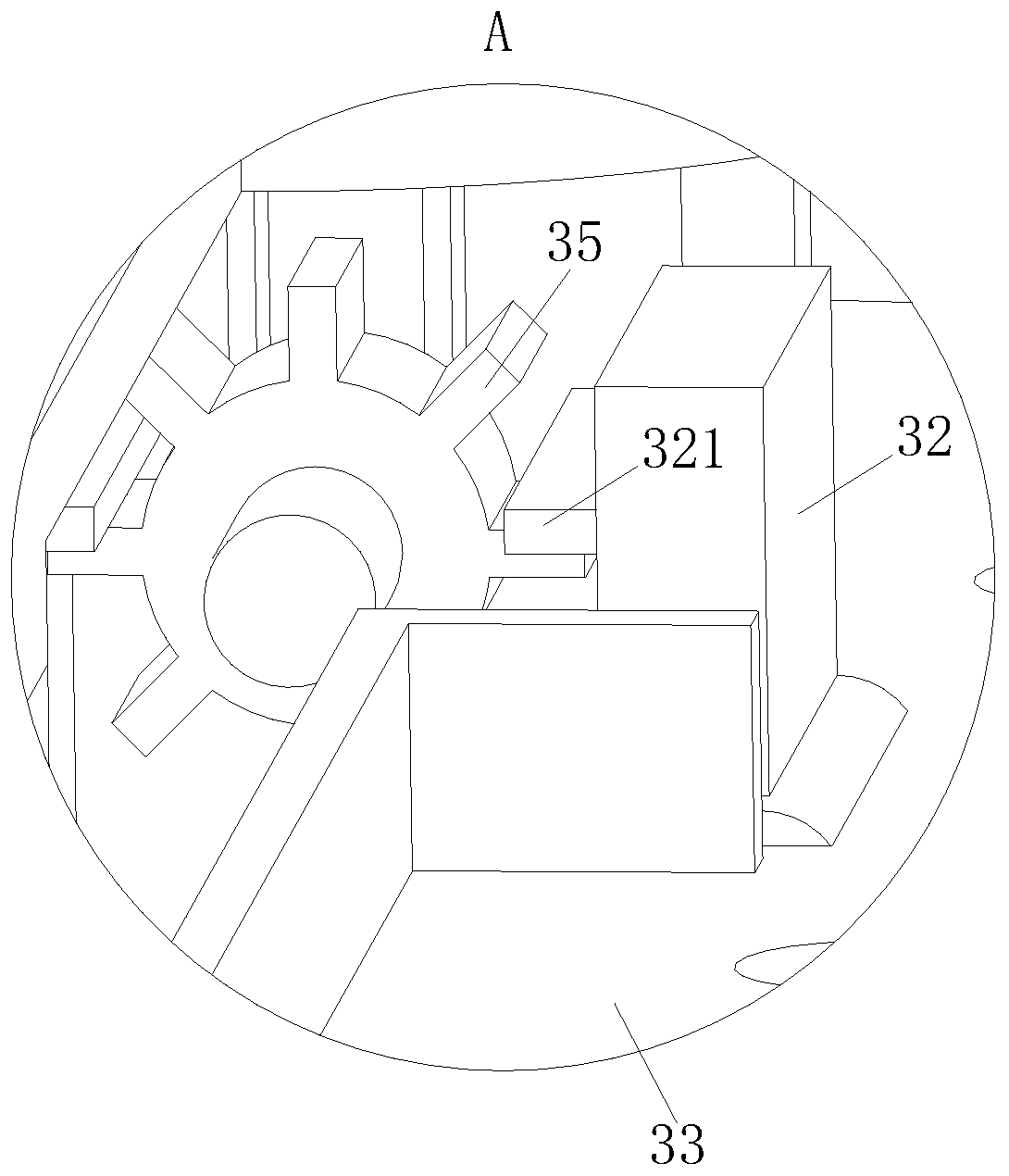

[0024] As an embodiment of the present invention, the No. 1 filter plate 33 is provided with an arc-shaped rod 36 on the side wall of the No. 1 filter plate 33 close to the casing 1, so that the No. 1 filter plate 33 is oscillated, and the casing 1 will face the arc-shaped rod. 36 is squeezed, and the bottom side of the No. 1 filter plate 33 is slidably connected with the No. 2 filter plate 37; the side wall of the No. 2 filter plate 37 is hinged with a push rod 372, and the end of the push rod 372 is in contact with the arc rod 36. The filter plate 37 is provided with a plurality of No. 2 filter holes 371; when the arc-shaped rod 36 is deformed under pressure, the No. 2 filter plate 37 is pushed by the push rod 372 to slide on the bottom side of the No. 1 filter plate 33, so as to realize the bottom of the filter plate 37. The wine tank on the side is further rolled and cleaned; when in use, during the swinging process of the No. 1 filter plate 33, the arc rod 36 will be drive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com