A kind of ecological lightweight filler and preparation method thereof

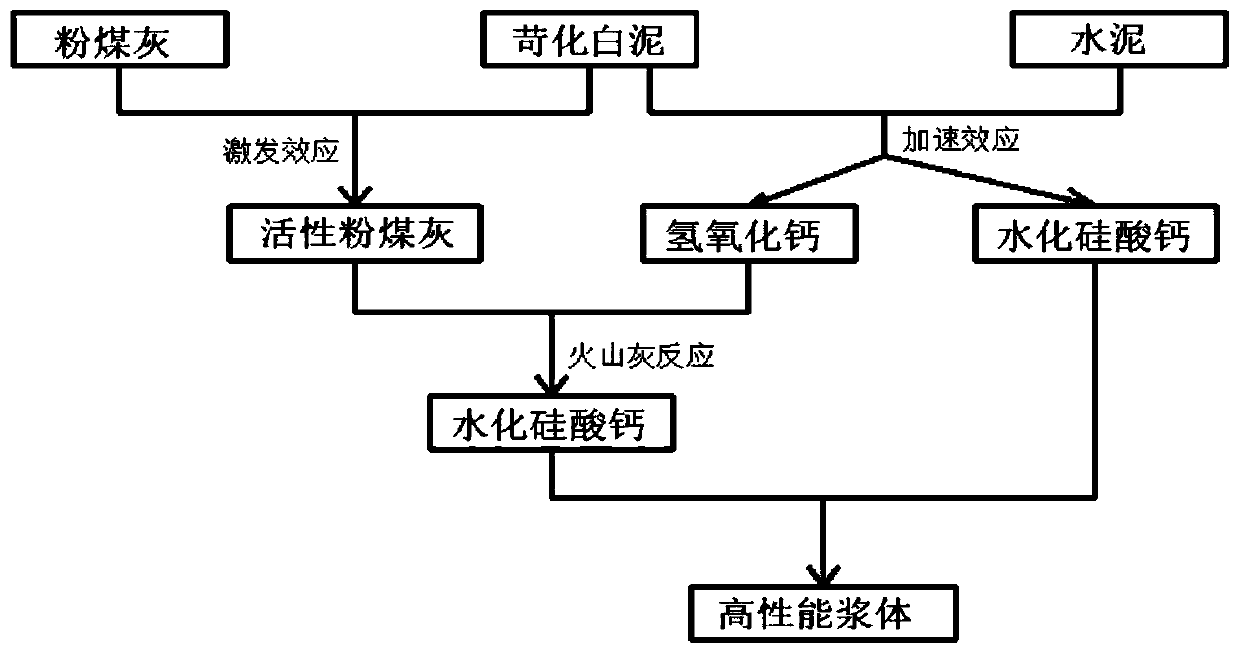

A lightweight filler and ecological technology, which is applied in the field of ecological lightweight filler and its preparation, can solve the problems of accelerated greenhouse effect, large amount of cement consumption, dust and soot, and achieve the effect of reducing dosage, saving engineering cost and improving workability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

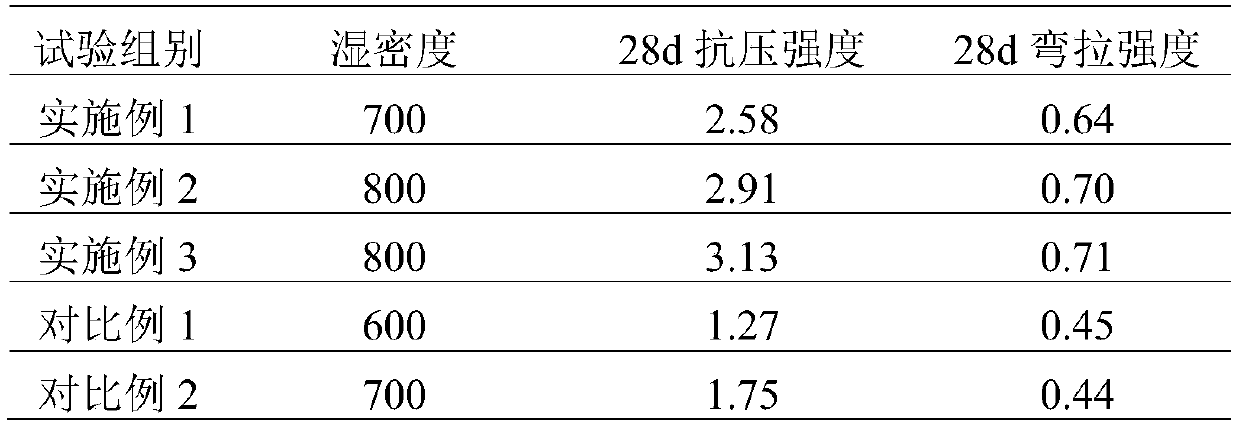

Embodiment 1

[0041] An ecological lightweight filler, prepared from the following raw materials in parts by mass: 13 parts of silty soil, 18 parts of cement, 30 parts of fly ash, 5 parts of caustic lime mud, water reducing agent (polycarboxylic acid series high-efficiency reducing Aqua) 0.02 parts, water 28 parts, foam 4 parts.

[0042] The preparation method of above-mentioned ecological lightweight filler, comprises the steps:

[0043] (1) 13 parts of silty soil and 4 parts of water are mixed and stirred evenly to prepare mud;

[0044] (2) 18 parts of cement, 30 parts of fly ash, 5 parts of causticized lime mud, 0.02 parts of water reducing agent and 24 parts of water were mixed and stirred evenly to prepare gelled slurry;

[0045] (3) mixing the obtained mud prepared in step (1) with the gelled slurry prepared in step (2) through a mixer;

[0046] (4) The composite cement blowing agent is diluted 40 times with water, and prepared into foam by a foaming machine; the expansion ratio is ...

Embodiment 2

[0050] An ecological lightweight filler, prepared from the following raw materials in parts by mass: 21 parts of silty soil, 12 parts of cement, 31 parts of fly ash, 5 parts of caustic lime mud, water reducing agent (polycarboxylic acid series high-efficiency reducing Aqua) 0.02 parts, water 26 parts, foam 3 parts.

[0051] The preparation method of above-mentioned ecological lightweight filler, comprises the steps:

[0052] (1) 21 parts of silty soil and 6 parts of water are mixed and stirred evenly to prepare mud;

[0053] (2) 12 parts of cement, 31 parts of fly ash, 5 parts of causticized lime mud, 0.02 parts of water reducer and 20 parts of water were mixed and stirred evenly to prepare a gelled slurry;

[0054] (3) mixing the obtained mud prepared in step (1) with the gelled slurry prepared in step (2) through a mixer;

[0055] (4) The composite cement blowing agent is diluted 40 times with water, and prepared into foam by a foaming machine; the expansion ratio is 900 t...

Embodiment 3

[0059] An ecological lightweight filler, prepared from the following raw materials in parts by mass: 14 parts of silty soil, 17 parts of cement, 32 parts of fly ash, 5 parts of caustic lime mud, water reducing agent (polycarboxylic acid series high-efficiency reducing Aqua) 0.02 parts, water 27 parts, foam 3 parts.

[0060] The preparation method of above-mentioned ecological lightweight filler, comprises the steps:

[0061] (1) 14 parts of silt and 5 parts of water are mixed and stirred evenly to prepare mud;

[0062] (2) 17 parts of cement, 32 parts of fly ash, 5 parts of causticized lime mud, 0.02 parts of water reducer and 22 parts of water were mixed and stirred evenly to prepare gelled slurry;

[0063] (3) mixing the obtained mud prepared in step (1) with the gelled slurry prepared in step (2) through a mixer;

[0064] (4) The composite cement blowing agent is diluted 40 times with water, and prepared into foam by a foaming machine; the expansion ratio is 900 times, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com