Elevator maintenance work support system

A technology that supports systems and operations, and is applied in lifts, transportation, and packaging, and can solve problems such as forgetting to switch back, bad situations, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

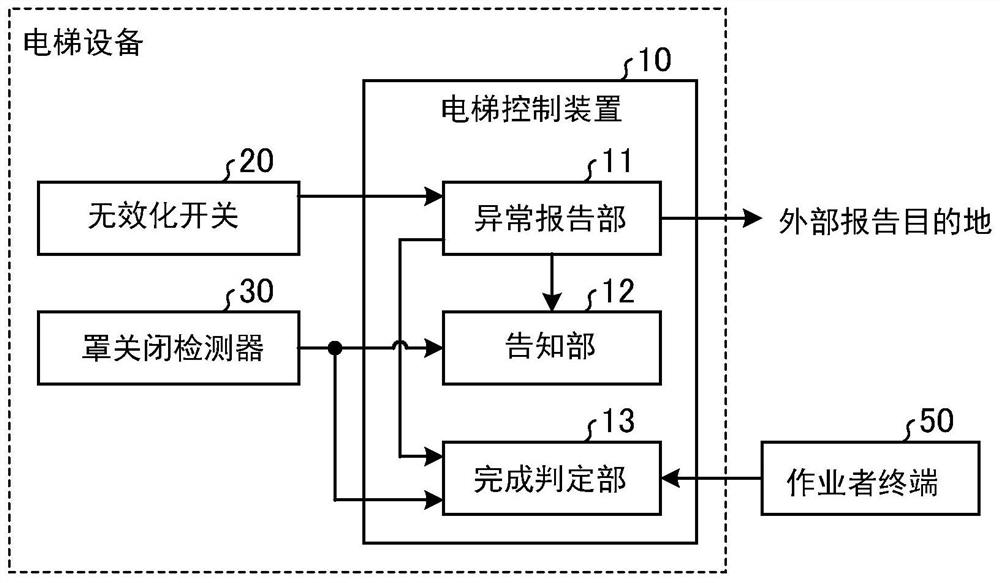

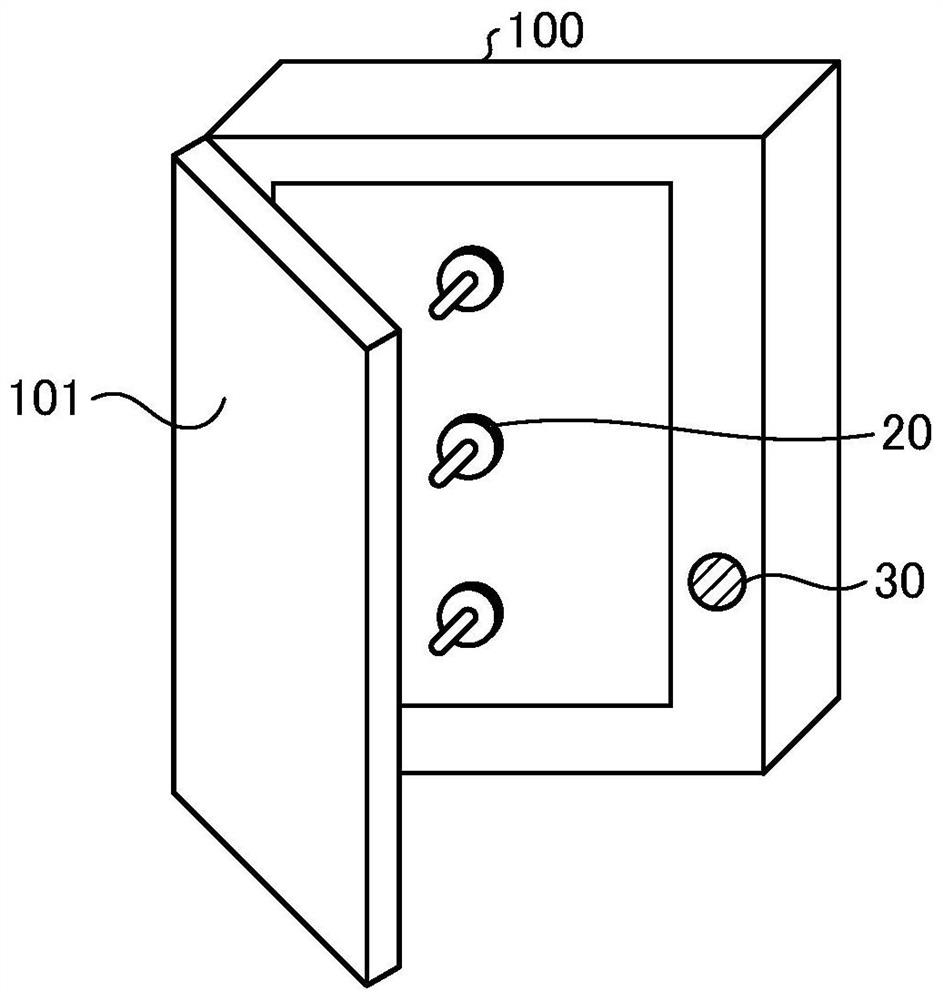

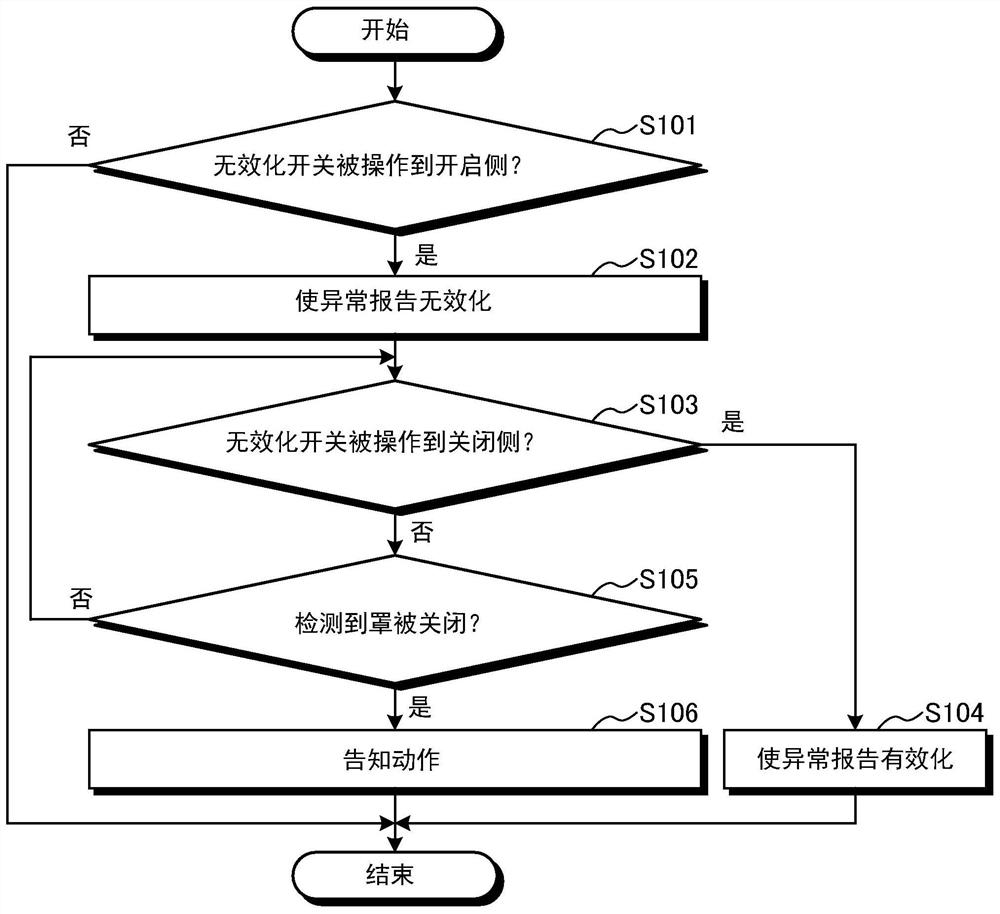

[0022] First, refer to figure 1 as well as figure 2 The configuration of the elevator maintenance work support system according to the first embodiment will be described. figure 1 It is a block diagram showing a configuration example of an elevator maintenance support system according to the first embodiment, figure 2 It is a perspective view of a housing provided with an invalidation switch.

[0023] Such as figure 1 As shown, the elevator maintenance work support system according to this embodiment includes an elevator control device 10 installed as elevator equipment, a nullification switch 20, a cover close detector 30, and an elevator maintenance work operator to operate. Operator terminal 50 .

[0024] The elevator control device 10 collects various information related to the operation of the elevator and controls the operation of the elevator. This elevator control device 10 includes an abnormality reporting unit 11 , a notification unit 12 , and a completion det...

no. 2 Embodiment approach

[0042] Next, a second embodiment will be described. An operator performing maintenance work may close the cover 101 of the housing 100 to start the maintenance work after turning the invalidation switch 20 to the ON side to disable the abnormality report of the abnormality reporting unit 11 . At this time, although the notification operation of the notification unit 12 is performed, it is assumed that the operator intends to return the invalidation switch 20 to the OFF side at the end of the maintenance work and ignore the notification operation. In this case, even if forgetting to return the disabling switch 20 occurs at the end of the maintenance work, it is impossible for the operator to notice the forgetting to return the disabling switch 20 .

[0043] Therefore, in the present embodiment, the elapsed time is measured from when the cover 101 of the housing 100 is closed when the abnormality report of the abnormality reporting unit 11 is disabled, and when the elapsed time ...

no. 3 Embodiment approach

[0052] Next, a third embodiment will be described. In this embodiment, when forgetting to return the invalidation switch 20, the abnormality report of the abnormality reporting part 11 can be validated by the command input from the elevator exterior. However, in order to prevent accidental activation of the abnormality report during maintenance work, the abnormality report is disabled and the cover 101 of the housing 100 is detected to be closed by the cover closing detector 30 as a condition. input the command. In addition, other functions and operations are the same as those of the above-mentioned first embodiment, so only the characteristic parts of this embodiment will be described below.

[0053] Figure 7 It is a block diagram showing a configuration example of an elevator maintenance work support system according to a third embodiment. In this embodiment, if Figure 7 As shown, a remote validating unit 15 is added as a functional component realized in the elevator c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com