An intelligent pipe bending machine for building plastic pipes

A technology for pipe benders and pipes, applied in non-electric variable control, instruments, control/regulation systems, etc., can solve problems such as difficulty in controlling the bending angle, plastic pipe bending, and labor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

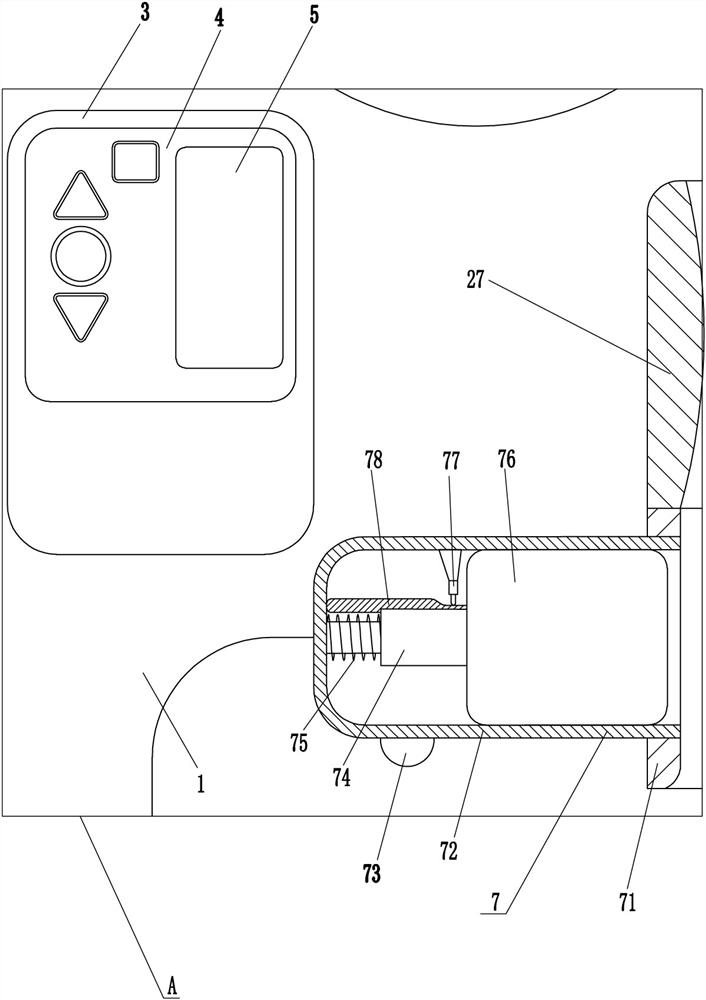

[0024] An intelligent pipe bending machine for building plastic pipes, such as figure 1 As shown, it includes a bottom plate 1, a pipe bending device 2 and an angle limiting mechanism 6. A pipe bending device 2 is provided on the rear side of the top of the bottom plate 1. The pipe bending device 2 is used to bend plastic pipes. The angle limiting mechanism 6 is connected to the pipe bending device 2, and the angle limiting mechanism 6 is used to control the bending angle of the plastic pipe.

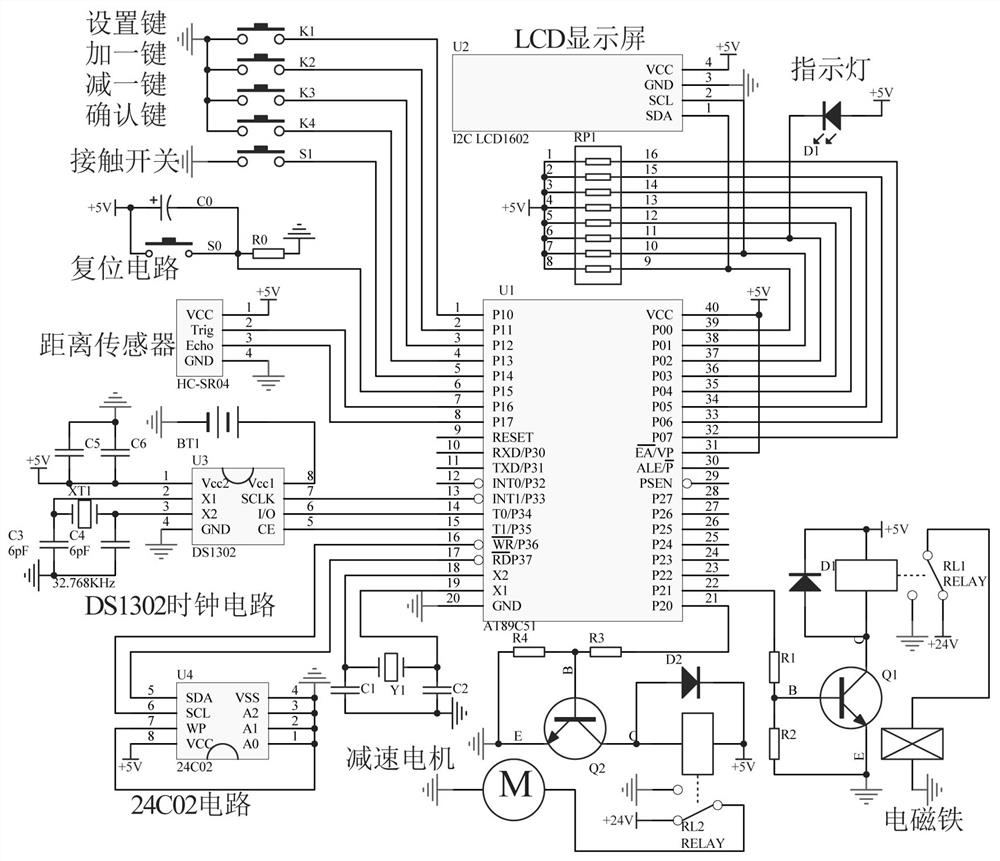

[0025] Such as figure 2 , Figure 6 and Figure 7 As shown, it also includes a control module, a setting key, a plus key, a minus key, a confirmation key and an LCD display 5, and the setting key, plus a key, minus a key, confirmation key and the LCD display 5 are all connected with the control module through electrical connection.

[0026] People press the main power switch to power on the device. When using it for the first time or need to adjust relevant parameters, people set t...

Embodiment 2

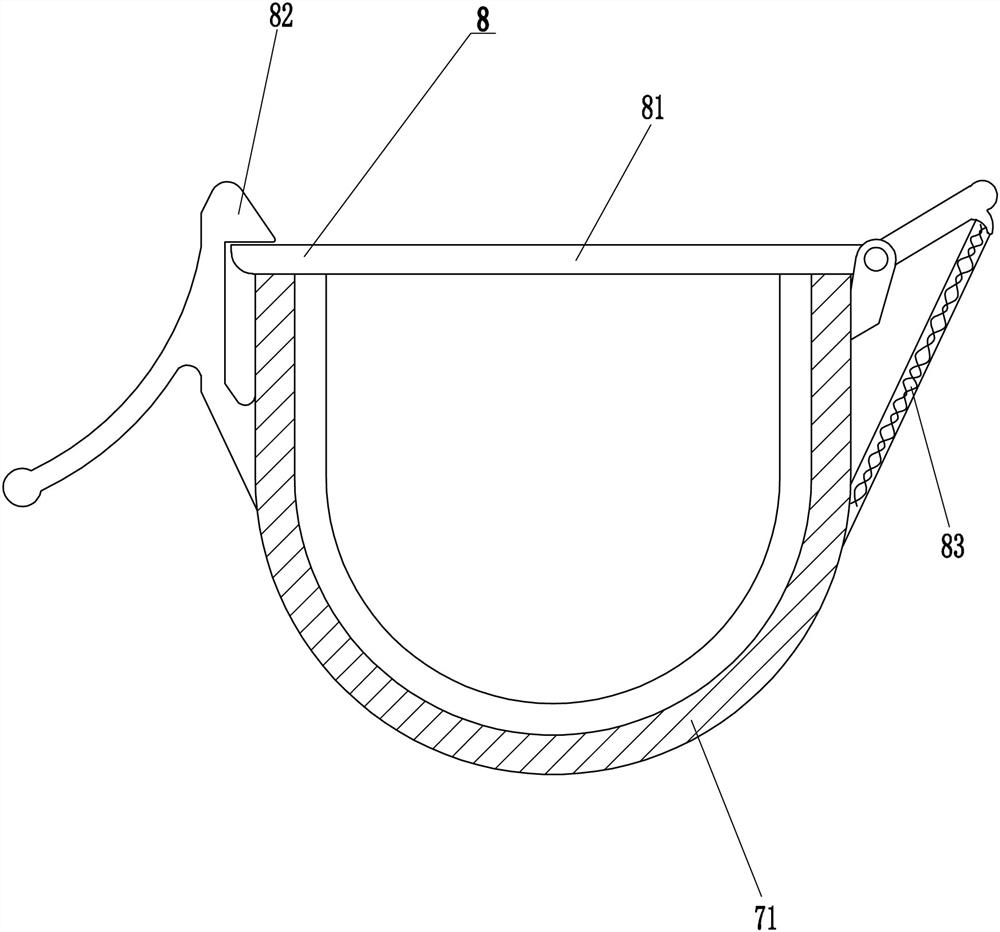

[0030] On the basis of Example 1, such as image 3As shown, the angle limiting mechanism 6 includes a reel 61, a stay cord 62, a guide sleeve 63, a mounting plate 64, a distance sensor 65, a guide rod 66, a first spring 67 and a baffle plate 68, and on the output shaft of the reduction motor 21 A reel 61 is installed, and the deceleration motor 21 is connected with the reel 61 by means of a key connection. The reel 61 is located below the rocker arm 22. A stay cord 62 is wound on the reel 61. The rear side of the top of the bottom plate 1 is connected with a Mounting plate 64, mounting plate 64 is positioned at geared motor 21 front sides, and guide bar 66 and distance sensor 65 are installed on the mounting plate 64, and mounting plate 64 is connected with guide bar 66 by the mode of bolt connection, and distance sensor 65 is positioned at the right side of guide bar 66 On the side, the guide rod 66 is covered with a guide sleeve 63, the stay rope 62 is connected with the gui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com