Edge covering and pressing automation system for vehicle door water trimming of vehicle Body in White

An automation system and body-in-white technology, applied in vehicle parts, transportation and packaging, etc., can solve the problems of inconsistent thickness of water trimming, abnormal noise of car doors, flashing and other problems, and achieve short debugging cycle, fast production cycle and good hemming effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

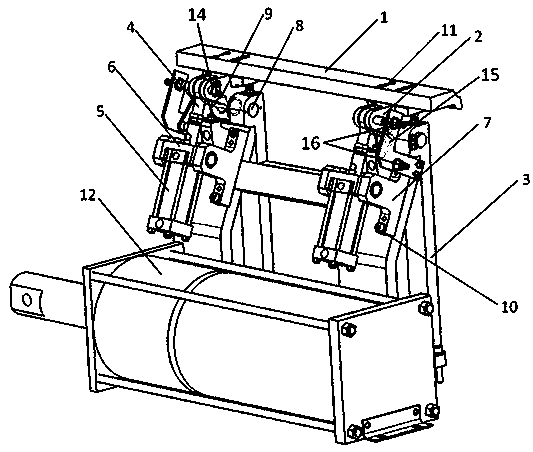

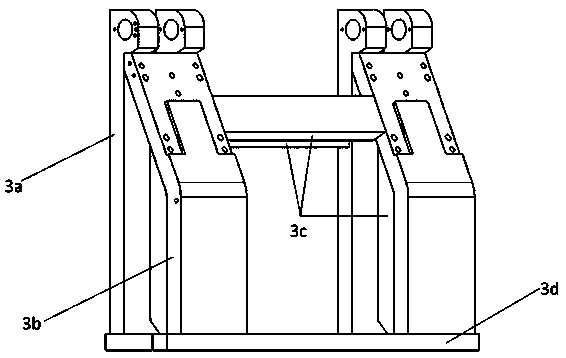

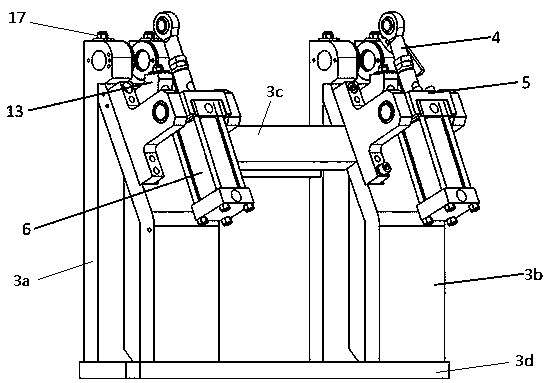

[0018] The invention provides an automatic system for water-cutting and edge-wrapping of automobile body-in-white doors, such as figure 1 Shown is the structure diagram of the present invention when the flap 1 in the present invention is in the pressing position, including a bracket 3, the bracket 3 includes a base plate 3d arranged in a horizontal direction, two type I support plates 3a, two type II supports Plate 3b and two ribs 3c, two type I support plates 3a are symmetrically arranged and vertically fixed on both ends of the upper surface of the base plate 3d, type II support plates 3b are arranged between the type I support plate 3a and the base plate 3d, type II support plates 3a One end of the support plate 3b is vertically fixed on the base plate 3d, and the other end is fixed on the corresponding Type I support plate 3a with an inclination angle. A reinforcing rib 3c is arranged between the two Type II support plates 3b, and the two Type I support plates 3a A reinfor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com