Device for reducing lead leaching mud

A technology of leaching lead and acid, applied in the direction of lead-acid battery electrodes, etc., can solve the problem of not being able to reduce the plate coating, etc., and achieve the effect of simple structure, easy adjustment, and prevention of offset position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

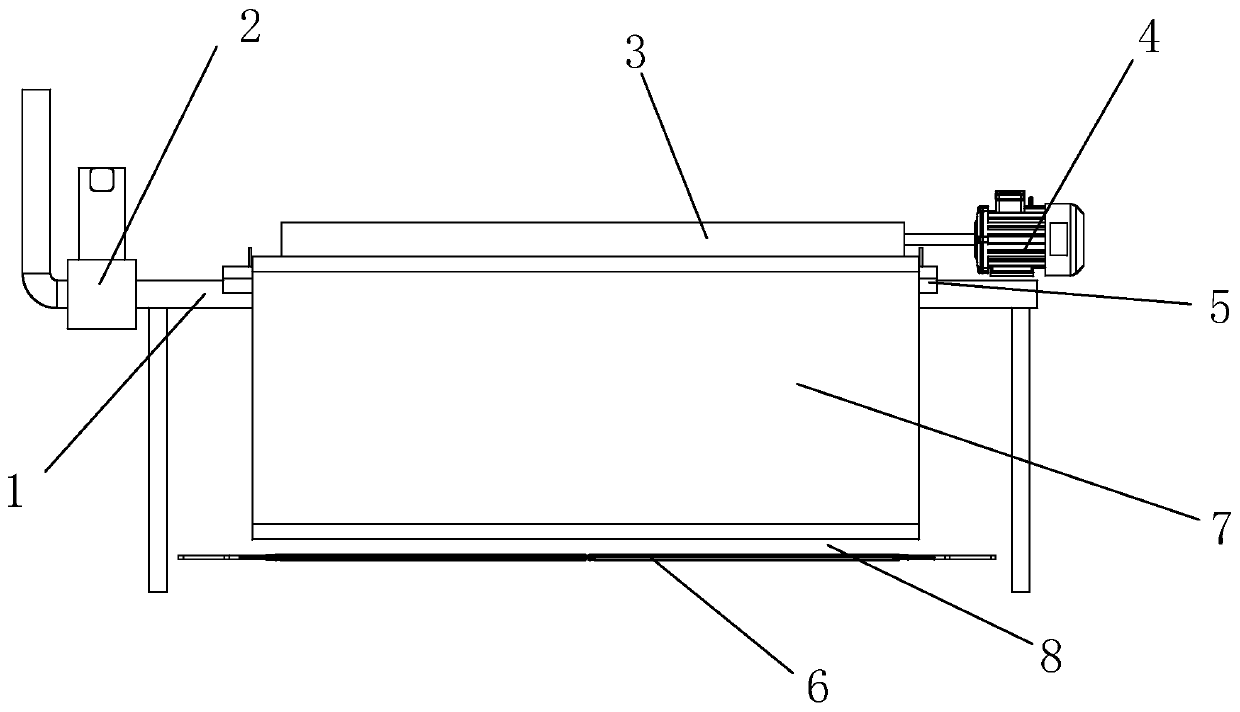

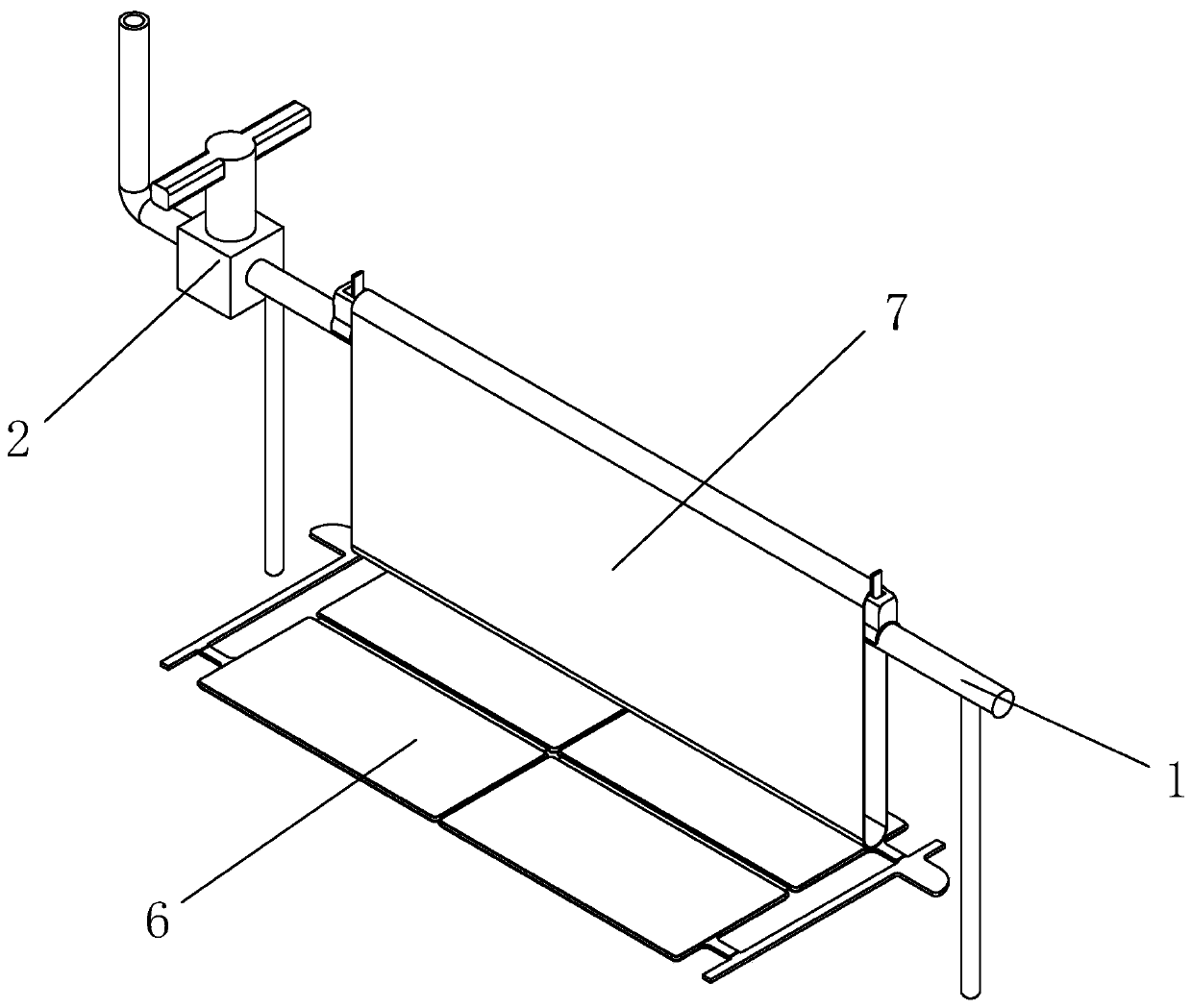

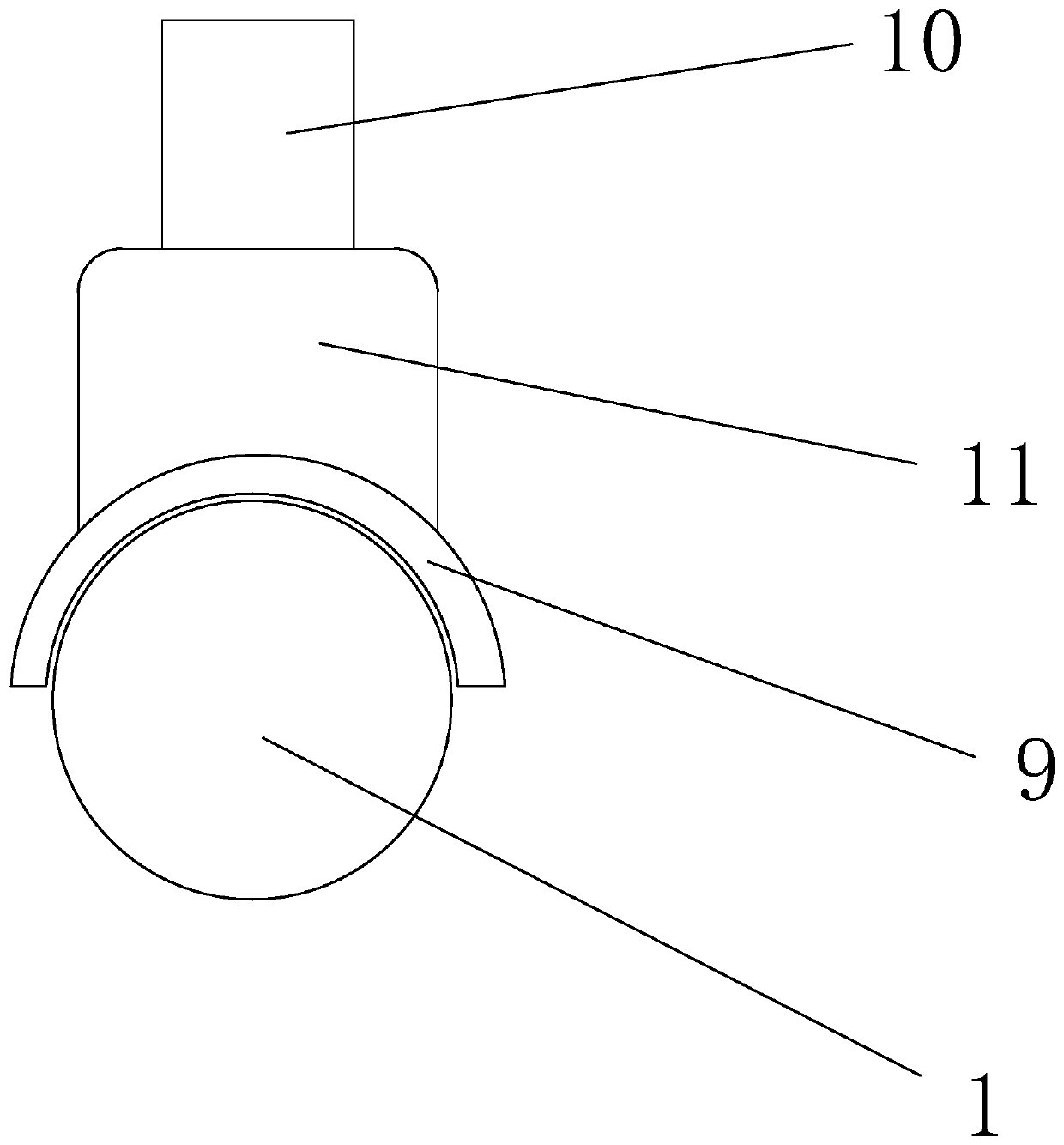

[0025] Such as figure 1 , 2Shown in , 4, a kind of device for reducing acid-leaching lead mud, comprises polar plate 6, end-to-end connection and the acid-leaching cloth 7 of opening at both ends and the acid-leaching pipe 1 that the interior is filled with sulfuric acid solution, and the acid-leaching cloth 7 is installed on the acid-leaching cloth On the pipe 1, the acid-drenched cloth 7 is made of acid-resistant polyester staple fiber, the acid-drenched cloth 7 is a multi-layer fine-grained non-woven fabric, and the surface of the cloth is a mesh structure, and the mesh structure on the surface of the acid-washed cloth 7 can be reversed. The acid drenched with acid is filtered again, and the length of the acid drenched cloth 7 is slightly greater than the length of the pole plate 6 joint plates, which can ensure that every position on the surface of the pole plate 6 can be drenched with acid, and the lower part of the acid drenched cloth 7 is parallel to and kept A certain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com