Novel suspended counterweight reservoir sediment dry bulk density sampling system

A sampling system and sediment technology, which are applied in the field of new type suspended counterweight reservoir sediment dry bulk density sampling system, can solve the problems of low sample fidelity, uncontrollable sediment sampler, high sampling accuracy, and improve drilling. Efficiency, easy to take out, and the effect of reducing the difficulty of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

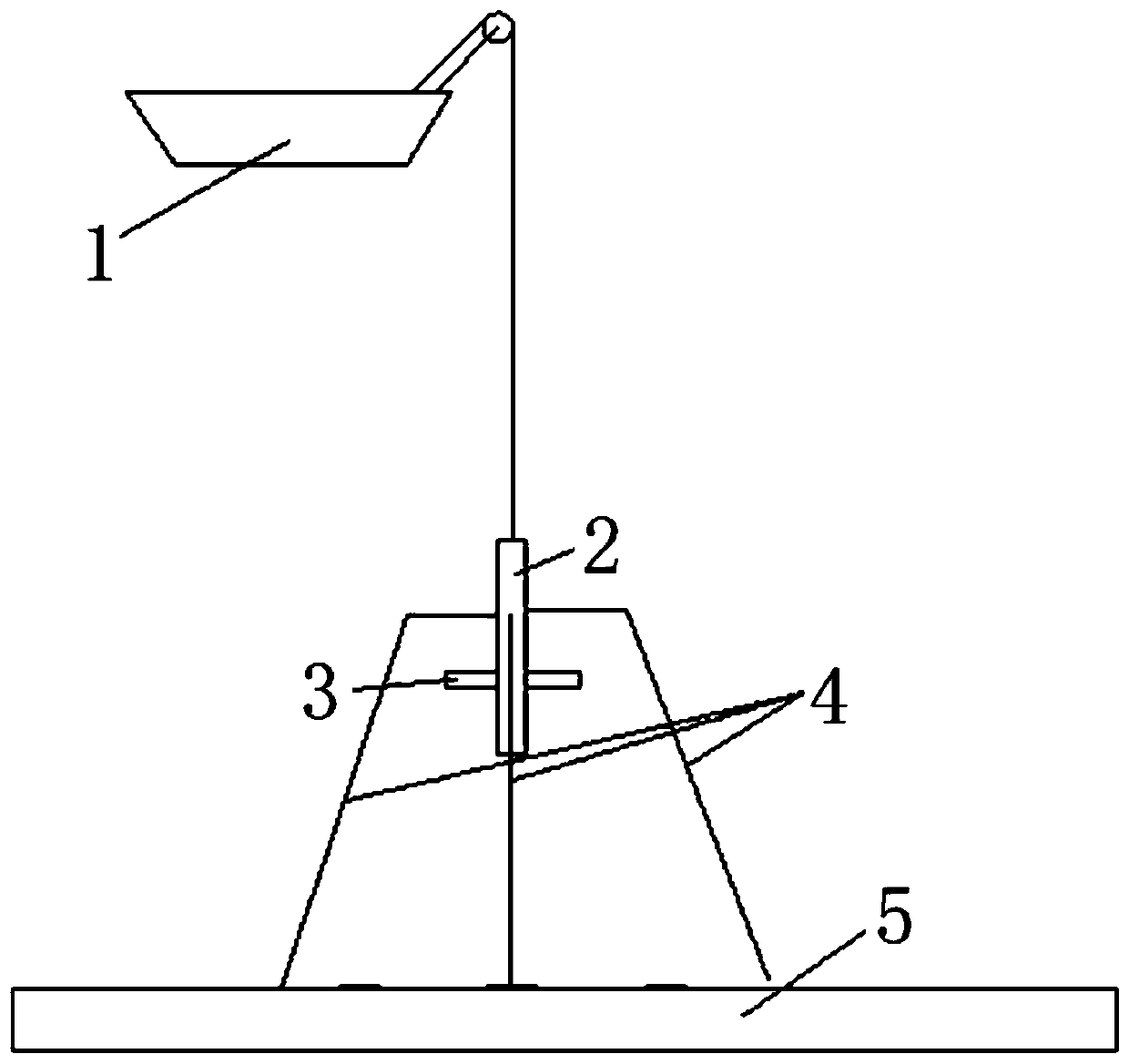

[0032] A novel steel cable suspended counterweight sediment sampling system of the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0033] The working principle of the device proposed by the present invention is as follows: figure 1 As shown, the whole sampling system is suspended by releasing a steel cable from the hoist on the survey ship 1, and the support frame 4 and the additional counterweight 3 are clamped on the sampler 2, and when the frame 4 touches the sediment layer 5, it will contact with the sampler 2 Separated, the additional counterweight 3 follows the sampler 2 into the drill.

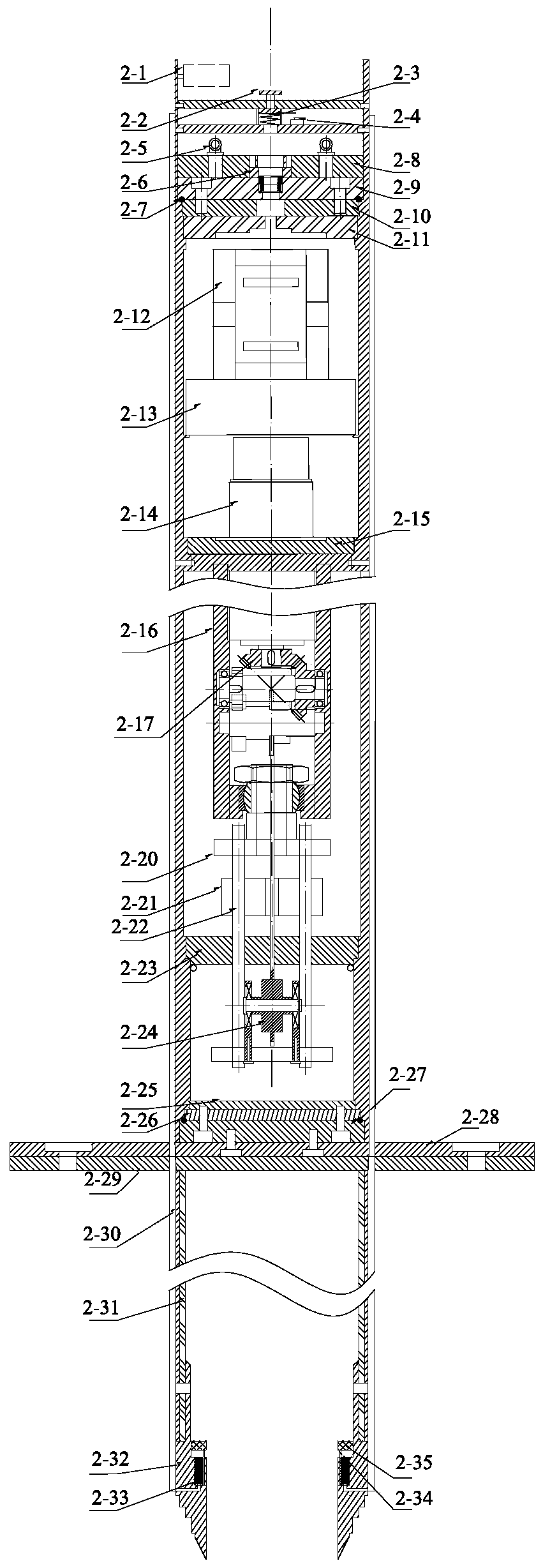

[0034] Please also refer to figure 2 One embodiment of the novel steel cable suspended counterweight sludge sampling system of the present invention includes a sampler 2, a support frame 4 and an additional counterweight 3, and the sampler 2 includes a drive cylinder, a sampling cylinder, and a drill bit.

[0035] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com