Container type generating unit

A generator set, containerized technology, applied in the direction of engine components, machines/engines, mechanical equipment, etc., can solve the problems of increased cost, excessive size, large length, etc., to improve the utilization rate of packing space and prevent the phenomenon of hot air backflow , the effect of reducing the difficulty of layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

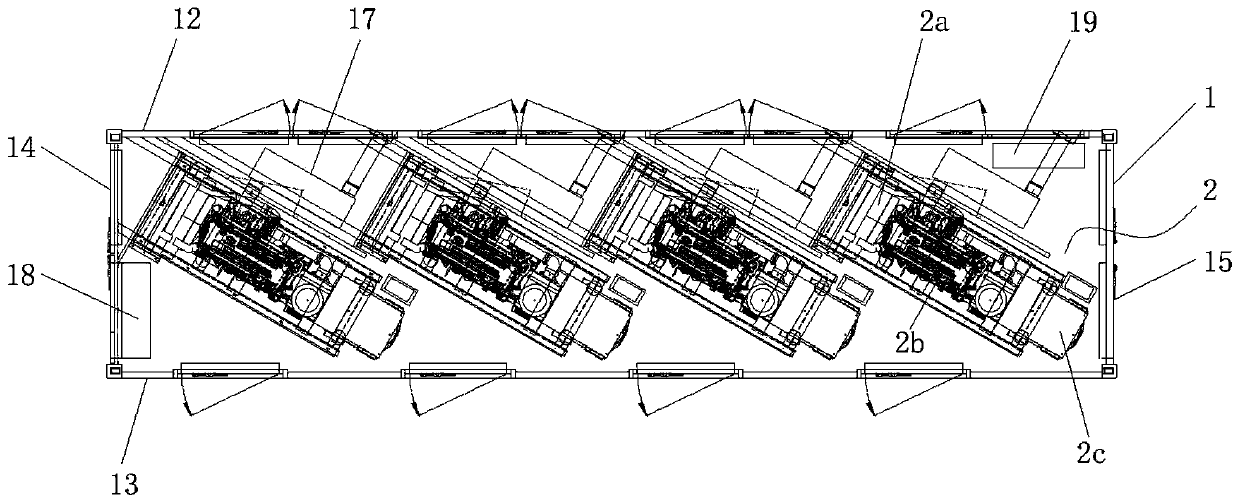

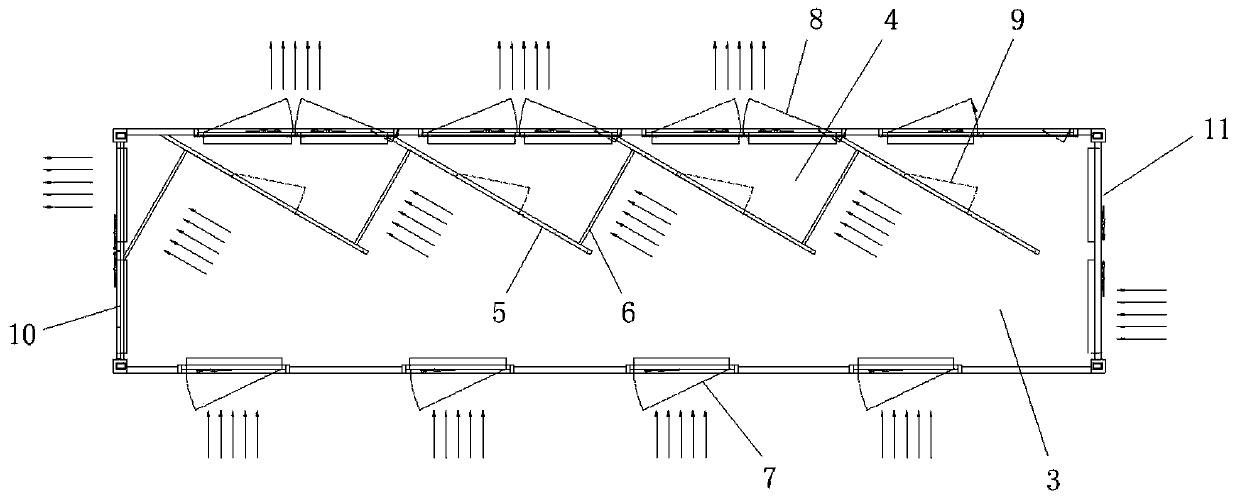

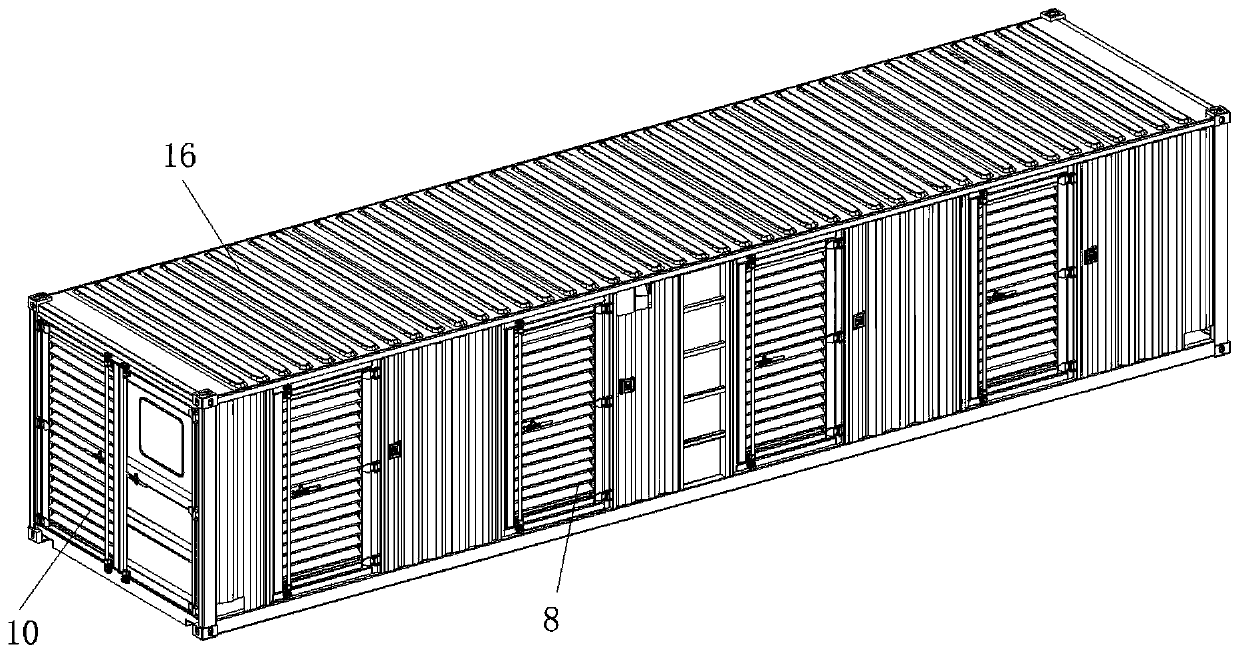

[0024] figure 1 It is a top view diagram of the internal structure of the present invention; figure 2 It is a top view diagram of the internal mechanism of the container of the present invention; image 3 Schematic for the three-dimensional structure of the present invention figure 1 ; Figure 4 Schematic for the three-dimensional structure of the present invention figure 2 .

[0025] As shown in the figure, the container-type generator set in this embodiment includes a container 1 and a plurality of generator sets 2 installed in the container, and the generator sets are installed obliquely and side by side in the container; The cuboid structure formed by the side wall 13, the left side wall 14, the right side wall 15, the top plate 16 and the bottom plate, in this embodiment, the front and rear directions are consistent with the container width, and the left and right directions are consistent with the container length direction, which will be described in detail below ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com