Construction method of integrated external wall building system

A technology that integrates exterior walls and construction methods, applied in the direction of walls, buildings, and building components, can solve the problems of low construction efficiency of masonry outside columns, easy production of convex beams, convex columns, and wall panels occupying the building area, etc., to improve The effects of production efficiency, reduction of production cost and increase of construction area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

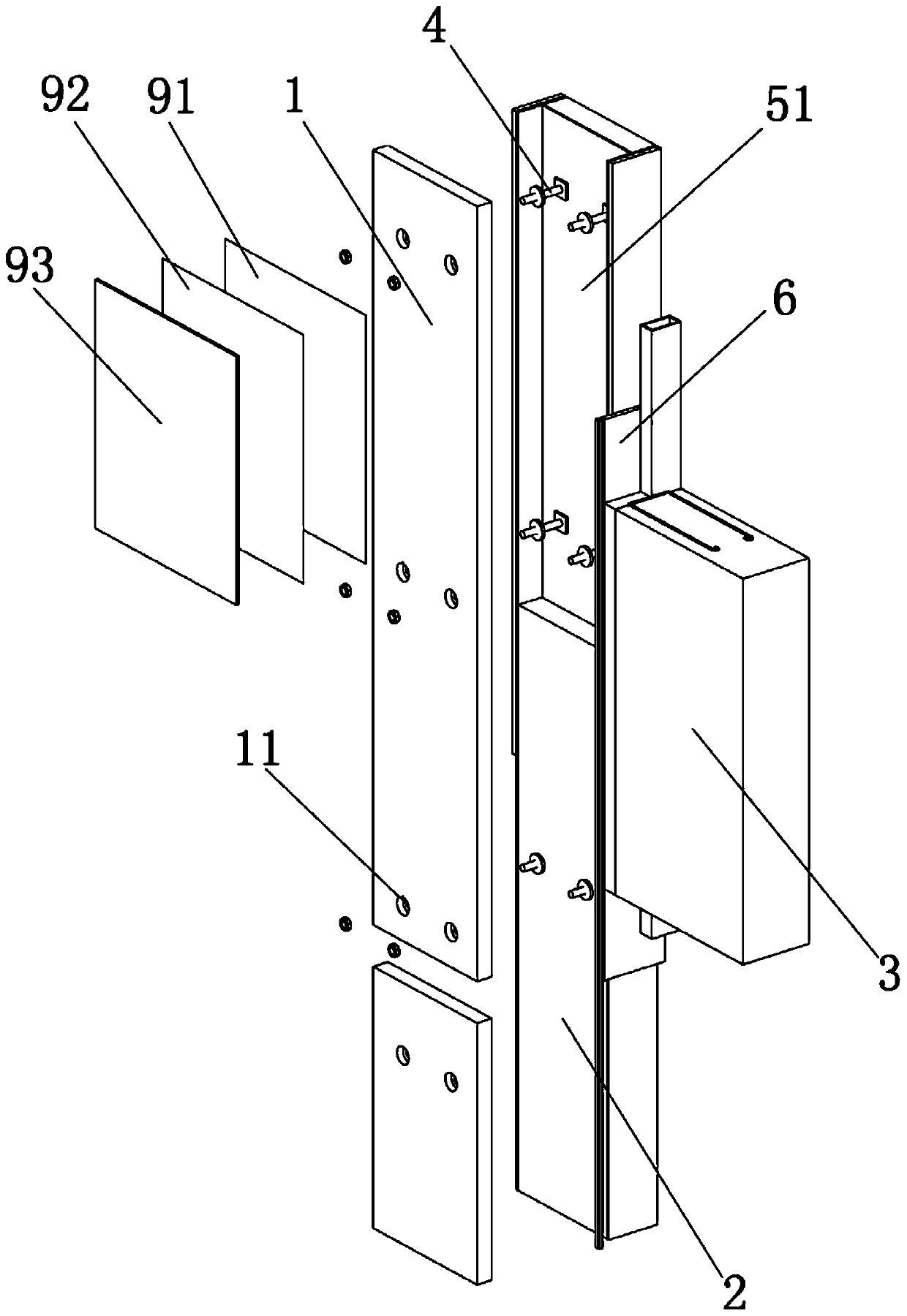

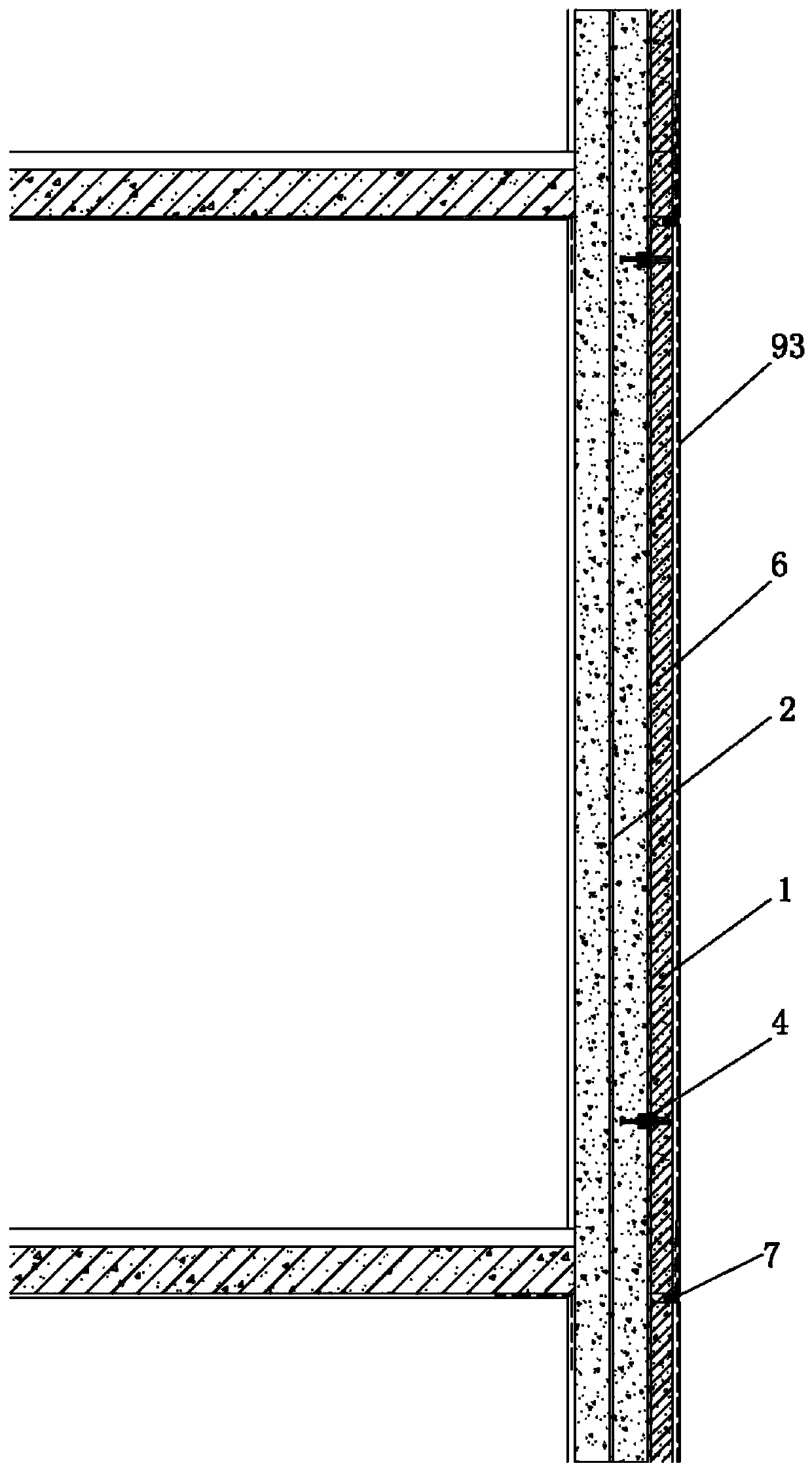

[0046] Please refer to the attached figure 1 to attach image 3 As shown, the present invention relates to an integrated exterior wall masonry system, which is composed of columns 2, prefabricated concrete slabs 1 and block exterior walls 3.

[0047] Wherein, the column 2 is fixed with a pre-embedded anchor bolt 4 . In this embodiment, the column 2 includes an H-shaped steel 5, and the H-shaped steel 5 is composed of a web 51 and a flange 52 welded to both ends of the web 51 and perpendicular to the web 51. The embedded anchor The bolt 4 is welded on the web 51 . Concrete 53 is filled between the flanges 52 in the H-shaped steel 5 to improve the structural strength of the column 2 and improve the fireproof effect of the column 2 . Of course, it is also possible not to fill the concrete as required.

[0048] The prefabricated concrete slab 1 is prefabricated in a factory, and a through hole 11 is opened on it. The embedded anchor bolt 4 passes through the through hole 11 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com