Precast pipe ring filled with light filler concrete and precasting method

A technology of concrete pipes and fillers, which is applied in the field of civil engineering, can solve problems such as large amount of reinforcement and difficulty in pouring pipe rings, and achieve the effects of green construction, saving raw materials, and improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0028] The invention provides a prefabricated concrete segment with built-in lightweight filler and a prefabrication method. The prefabricated concrete segment with built-in lightweight filler can be applied to underground projects constructed by prefabricated assembly methods, including but not limited to pipe jacking tunnels, underground pipe Corridor etc.

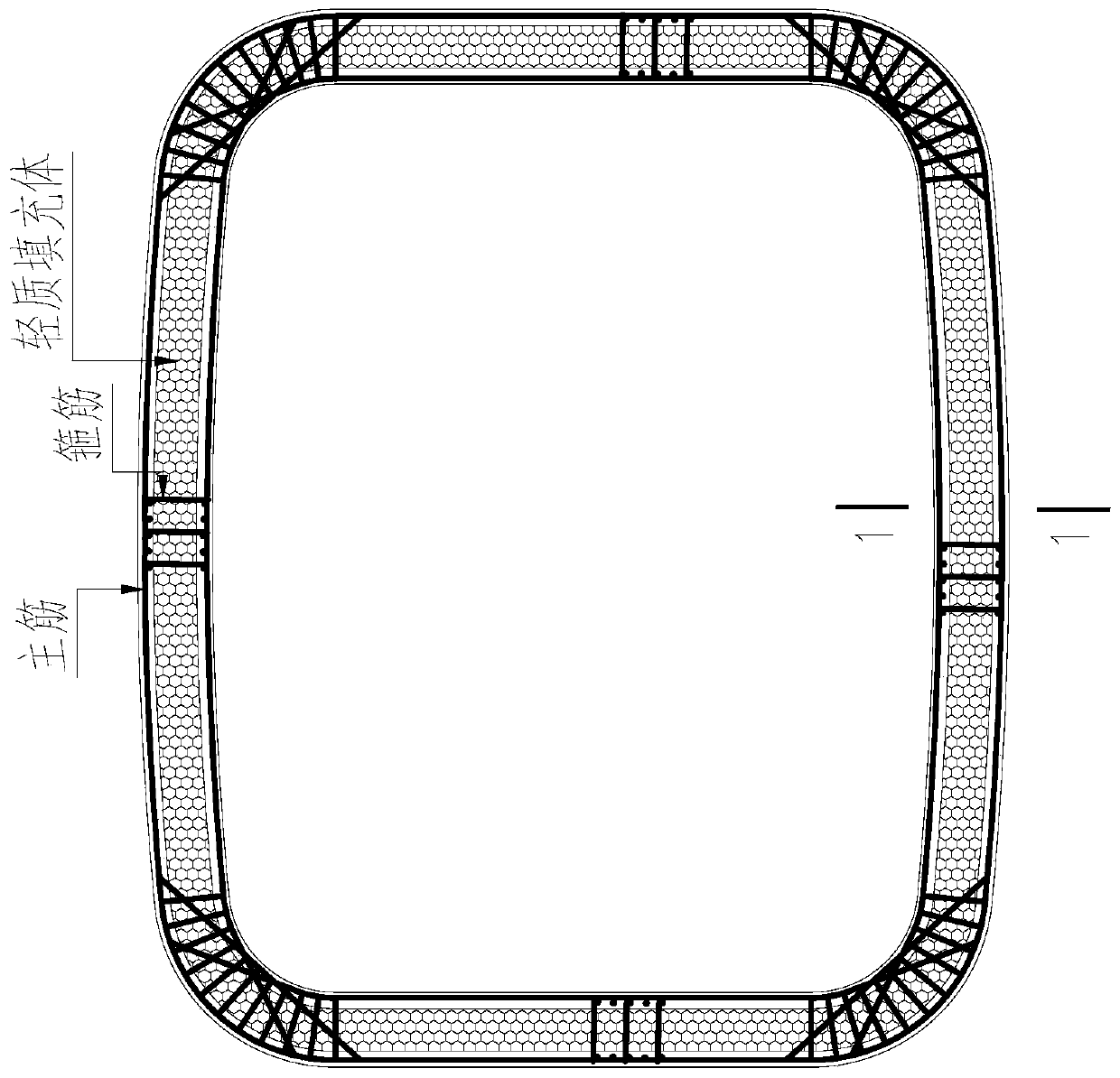

[0029] The structure of the prefabricated built-in lightweight concrete pipe ring is as follows: Figure 1-4 As shown, it includes the pipe ring skeleton, the lightweight filling body arranged in the pipe ring skeleton, and the pipe ring body formed by layered casting. The stirrups are composed of lightweight fillers, which are arranged in the cavity surrounded by the main body of the skeleton and the stirrups, and fixed on the main ribs by hooks.

[0030] The material of the prefabricated concrete pipe ring with built-in lightweight filler can be steel (fiber) reinforced concrete, fiber steel (fiber) reinforced concret...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com