A kind of α-amylase inhibitor and its preparation process and application

An amylase inhibitor and preparation technology, applied in the field of α-amylase inhibitors, to achieve the effects of high purity, mild reaction conditions, and good heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

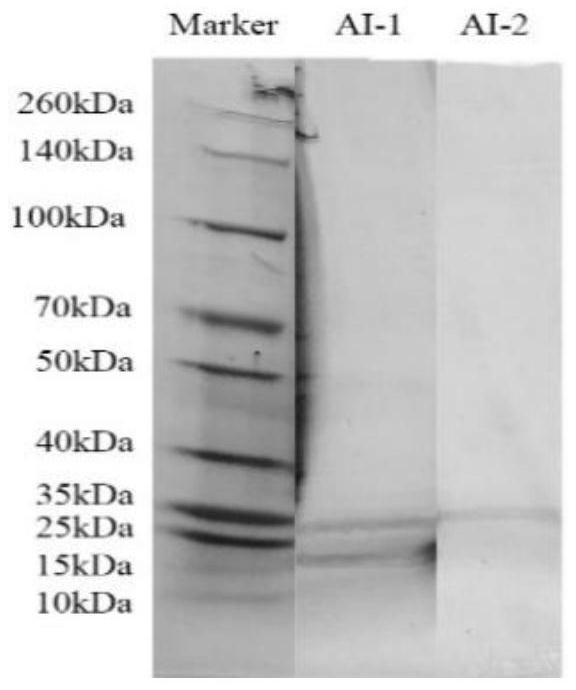

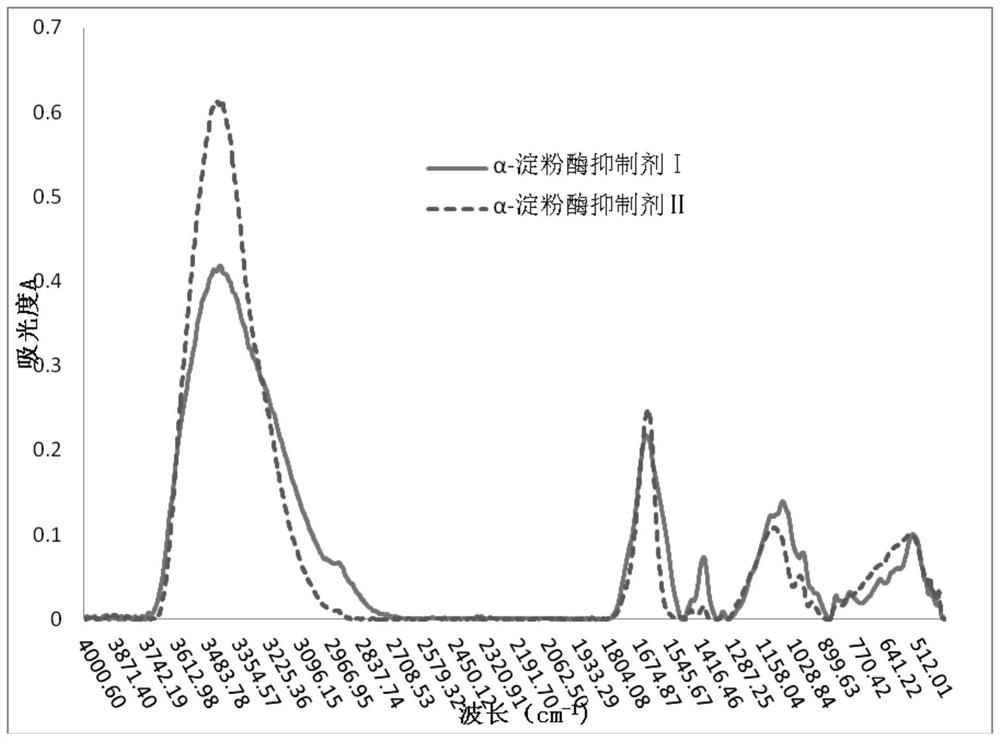

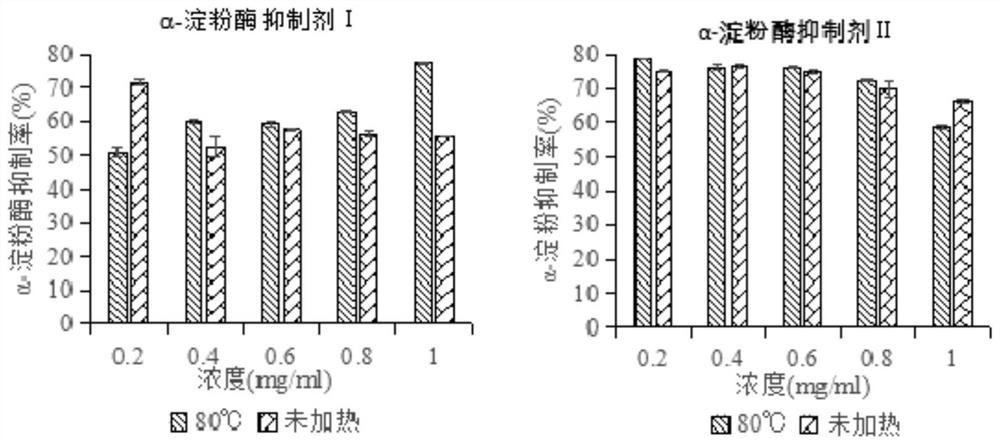

[0053] The α-amylase inhibitor provided in this example is a protein isolated from seabuckthorn seed meal, and the preparation process includes:

[0054] The seabuckthorn seed meal was pulverized into fine particles with a pulverizer and sieved to obtain seabuckthorn raw material powder with a particle size of 80 mesh, which was stored in a -20°C refrigerator for later use.

[0055]Add 25 times its weight of 50% ethanol solution to 10 g of raw material powder, and stir at 300 rpm / min for 2 hours at 50° C. to obtain a mixed solution. The resulting mixed solution was filtered with gauze to obtain a filtrate and a first precipitate. The obtained filtrate was subjected to sedimentation and centrifugation, and was centrifuged at 6000 rpm / min for 15 minutes to obtain the second precipitate. The first precipitate obtained and the second precipitate obtained were combined. The resulting combined precipitate was repeated twice. The finally obtained precipitates were combined and dri...

Embodiment 2

[0064] The α-amylase inhibitor provided in this example is a protein isolated from seabuckthorn seed meal, and the preparation process includes,

[0065] The seabuckthorn seed meal was pulverized into fine particles with a pulverizer and sieved to obtain seabuckthorn raw material powder with a particle size of 60 mesh, which was stored in a -20°C refrigerator for later use.

[0066] Add 30 times its weight of 65% ethanol solution to 10 g of seabuckthorn raw material powder, and stir at 500 rpm / min for 0.5 h at 65° C. to obtain a mixed solution. The resulting mixed solution was filtered with gauze to obtain a filtrate and a first precipitate. The obtained filtrate was subjected to sedimentation and centrifugation treatment, and was centrifuged at 5000 rpm / min for 20 minutes to obtain the second precipitate. The resulting combined precipitate was repeated twice. The finally obtained precipitates were combined and dried at 45° C. for 2 hours to obtain seabuckthorn seed meal pro...

Embodiment 3

[0071] The α-amylase inhibitor provided in this example is a protein isolated from seabuckthorn seed meal, and the preparation process includes,

[0072] The seabuckthorn seed meal was crushed into fine particles with a pulverizer and sieved to obtain seabuckthorn raw material powder with a particle size of 100 mesh, which was stored in a -20°C refrigerator for later use.

[0073] Add 20 times its weight of 75% ethanol solution to 10 g of raw material granules (raw material powder), stir at 45° C. and 200 rpm / min for 3 h to obtain a mixed solution. The resulting mixed solution was filtered with gauze to obtain a filtrate and a first precipitate. The obtained filtrate was subjected to sedimentation and centrifugation treatment, and was centrifuged at 8000 rpm / min for 10 minutes to obtain the second precipitate. The resulting combined precipitate was repeated twice. The finally obtained precipitates were combined and dried at 60° C. for 0.5 h to obtain seabuckthorn seed meal p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com