Alpha-amylase inhibitor and preparation technology and application thereof

An amylase inhibitor and the technology of its preparation process are applied in the field of α-amylase inhibitors to achieve the effects of lowering blood sugar, mild reaction conditions and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

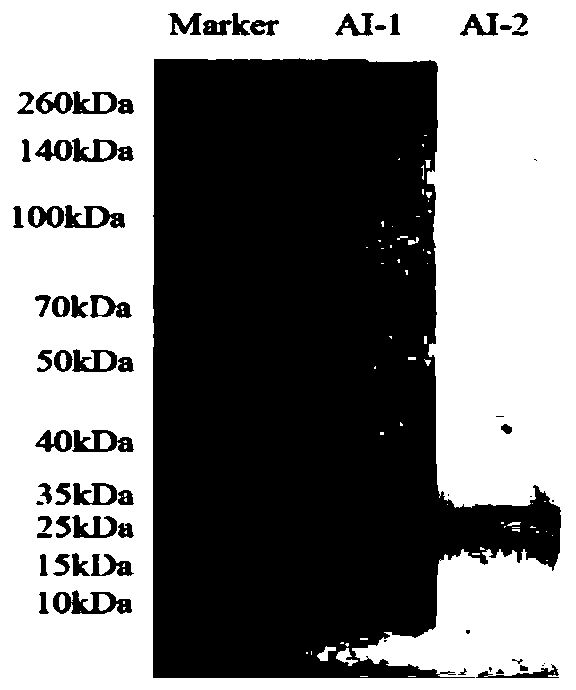

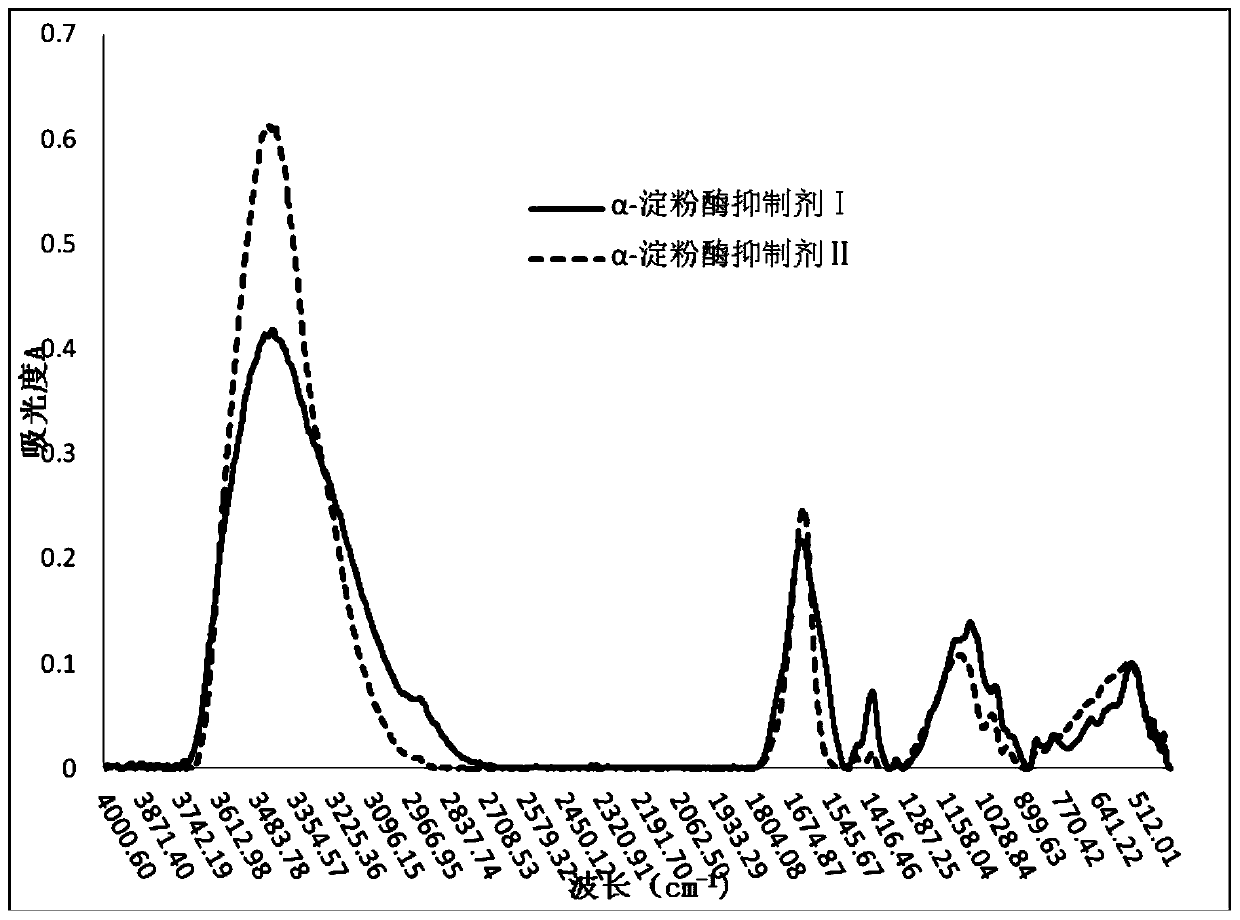

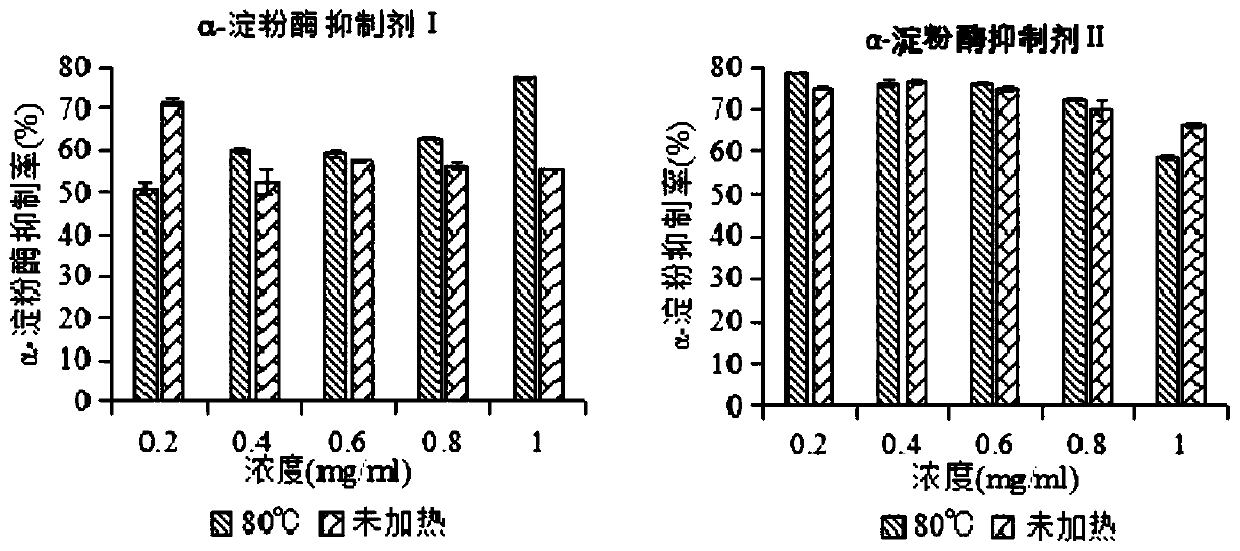

[0053] The α-amylase inhibitor provided in this example is a protein isolated from seabuckthorn seed meal, and the preparation process includes:

[0054] The seabuckthorn seed meal was pulverized into fine particles with a pulverizer and sieved to obtain seabuckthorn raw material powder with a particle size of 80 mesh, which was stored in a -20°C refrigerator for later use.

[0055]A 50% ethanol solution of 25 times its weight was added to 10 g of the raw material powder, and the mixture was stirred at 300 rpm / min for 2 hours at a temperature of 50° C. to obtain a mixed solution. The resulting mixed solution was filtered with gauze to obtain a filtrate and a first precipitate. The obtained filtrate was subjected to sedimentation centrifugation, and centrifuged at 6000 rpm / min for 15 min to obtain a second precipitate. The resulting first precipitate and the resulting second precipitate are combined. The resulting combined precipitate was repeated the above operation twice. ...

Embodiment 2

[0064] The α-amylase inhibitor provided in this embodiment is a protein isolated from sea buckthorn seed meal, and the preparation process includes,

[0065] The sea buckthorn seed meal was pulverized into fine particles with a pulverizer and sieved to obtain sea buckthorn raw material powder with a particle size of 60 meshes, which was stored in a -20°C refrigerator for later use.

[0066] A 65% ethanol solution of 30 times its weight was added to 10 g of seabuckthorn raw material powder, and the mixture was stirred for 0.5 h at 500 rpm / min at a temperature of 65° C. to obtain a mixed solution. The resulting mixed solution was filtered with gauze to obtain a filtrate and a first precipitate. The obtained filtrate was subjected to sedimentation centrifugation, and centrifuged at 5000 rpm / min for 20 min to obtain the second precipitate. The resulting combined precipitate was repeated the above operation twice. The final obtained precipitates were combined and dried at 45° C. ...

Embodiment 3

[0071] The α-amylase inhibitor provided in this embodiment is a protein isolated from sea buckthorn seed meal, and the preparation process includes,

[0072] The sea buckthorn seed meal was pulverized into fine particles with a pulverizer and sieved to obtain sea buckthorn raw material powder with a particle size of 100 meshes, which was stored in a -20°C refrigerator for later use.

[0073] 20 times its weight of 75% ethanol solution was added to 10 g of raw material particles (raw material powder), and stirred at 45° C. for 3 hours at 200 rpm / min to obtain a mixed solution. The resulting mixed solution was filtered with gauze to obtain a filtrate and a first precipitate. The obtained filtrate was subjected to sedimentation centrifugation, and centrifuged at 8000 rpm / min for 10 min to obtain the second precipitate. The resulting combined precipitate was repeated the above operation twice. The final obtained precipitates were combined and dried at a temperature of 60° C. for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com