A kind of bioceramic slurry and preparation method thereof for high-performance dlp printing

A bioceramic, high-performance technology, applied in the field of high-performance DLP printing bioceramic slurry and its preparation, to achieve the effect of reducing degreasing cracking, high precision, and high solid phase content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

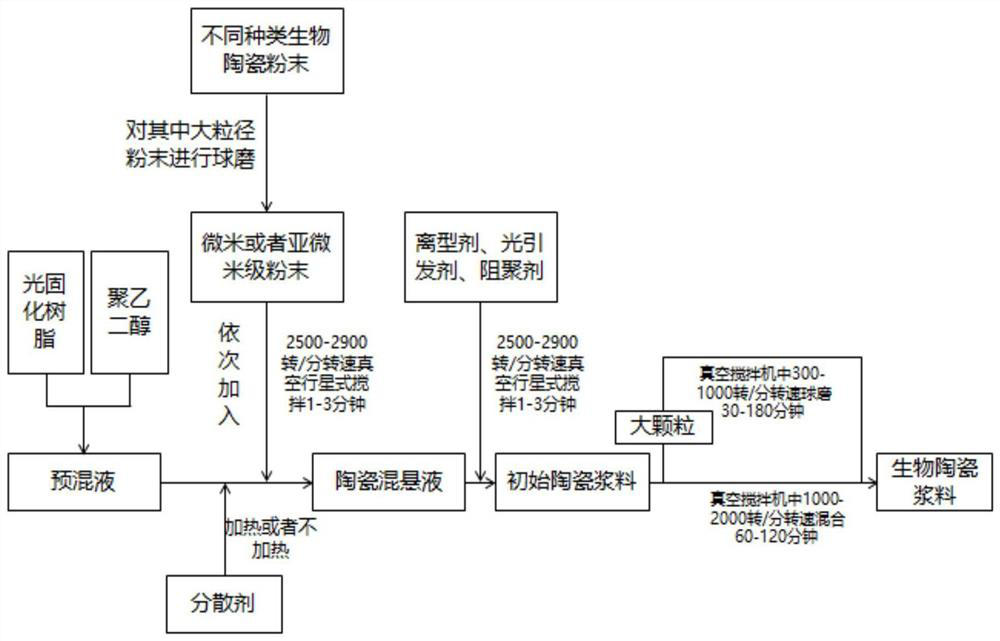

[0038] Such as figure 1 Shown, the preparation method of bioceramic slurry of the present invention comprises the following steps:

[0039] (1) After uniformly mixing the photocurable resin and polyethylene glycol in a preset ratio to form a premix solution, the premix solution includes polyethylene glycol and photocurable resin in a mass ratio of 3:20-2:5.

[0040] (2) Add a dispersant to the above premix, heat or not heat it to dissolve in the premix, stir evenly, and ultrasonicate for 5 minutes, the mass of the dispersant is 0.5% to 6% of the mass of the bioceramic powder .

[0041] (3) Dry the bioceramic powder, put it into an oven to remove moisture, if the bioceramic powder particle is too large, then ball mill it for 5 hours to 8 hours to obtain a micron-sized bioceramic powder, The average particle size of the bioceramic powder is between 0.2 μm and 40 μm.

[0042] (4) Weigh the micron-sized bioceramic powder and add it to the prepared solvent several times. The mas...

Embodiment example 1

[0046] This example uses β calcium phosphate powder and biological glass powder 45S5 composite powder, wherein β calcium phosphate and biological glass are mixed in a certain mass ratio, the particle size of β calcium phosphate powder is micron level, and the average particle size is 4.66 μm. The average particle size is about 6 μm. A total of 62 grams of bioceramic powder is selected, and the premix is 35 grams. The photocurable resin is selected from difunctional 1,6-hexanediol diacrylate monomer and difunctional tripropylene glycol diacrylate The acrylate monomers have a mass of 19 grams and 8 grams, respectively. Polyethylene glycol is selected polyethylene glycol 200, and quality is 8 grams. Among them, the quality of the hyperdispersant is 2.48 grams, the release agent is selected from acrylate modified silicone oil, and the quality is 0.62 grams, and the photoinitiator is selected from 2,4,6-trimethylbenzoyl-diphenylphosphine oxide, and the quality is 0.177 Gram, pol...

Embodiment 2

[0053] The composition and the content of each component of the premix of Example 2 are the same as Example 1, and the mass fraction of the bioceramics and the amount of the dispersant and the content of the polymerization inhibitor are different, and the differences are shown in Table 1 below:

[0054] Table 1:

[0055]

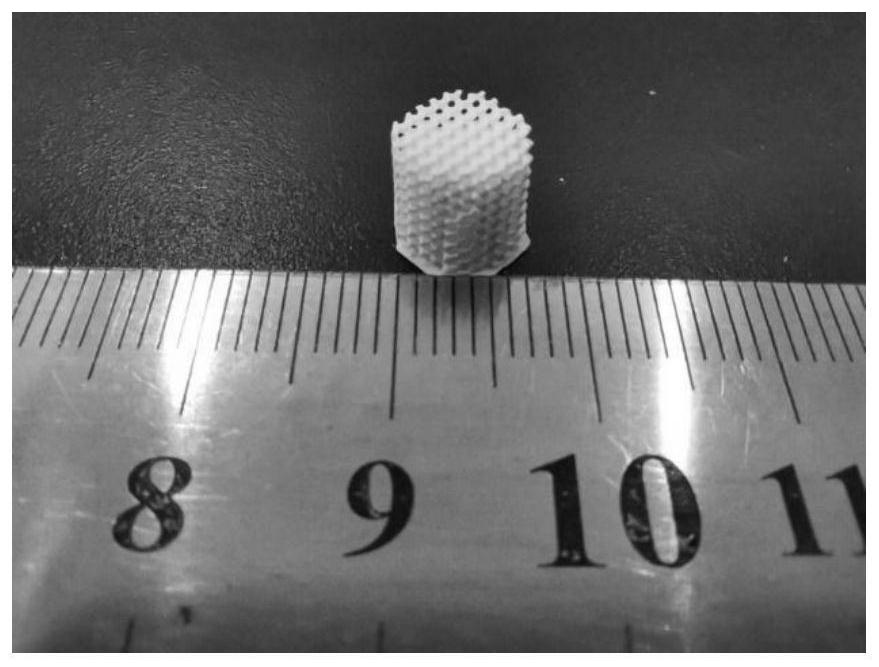

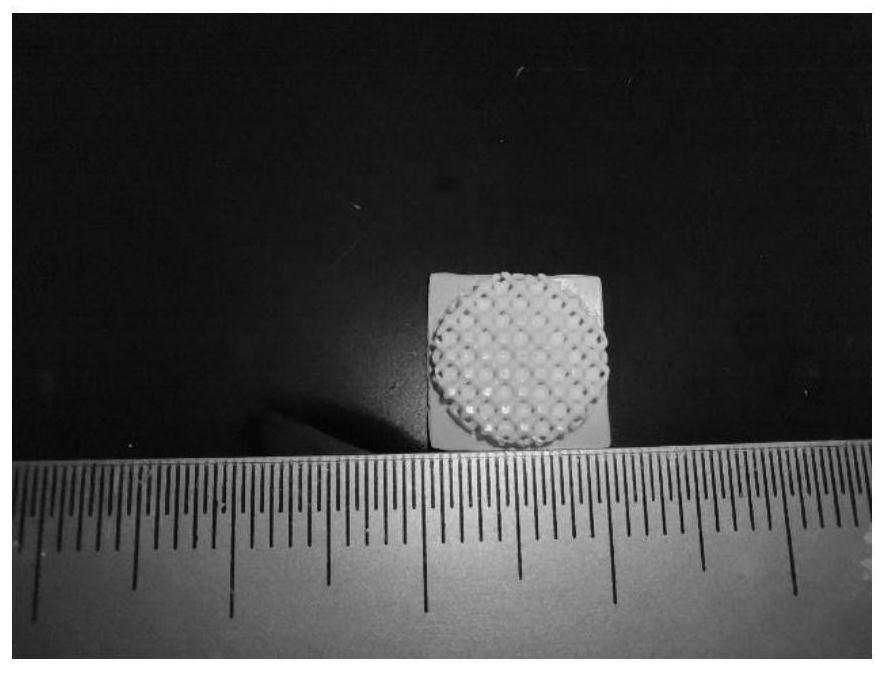

[0056] Such as image 3 and Figure 5 As shown, the average flexural strength of the bioceramics printed under this ratio reaches 24Mpa, and the accuracy is improved compared with Example 1, but the thickness of the cured layer is reduced, but it still has a good release effect.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com