Water permeable brick capable of removing various pollutants and preparation method thereof

A technology of pollutants and permeable bricks, applied in clay products, other household appliances, roads, etc., can solve the problems of heavy metal overflow, clogging of inorganic particles of adsorbent materials, and disorderly distribution, etc., to extend service life, reduce resistance coefficient, and increase maintenance. effect of cycles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

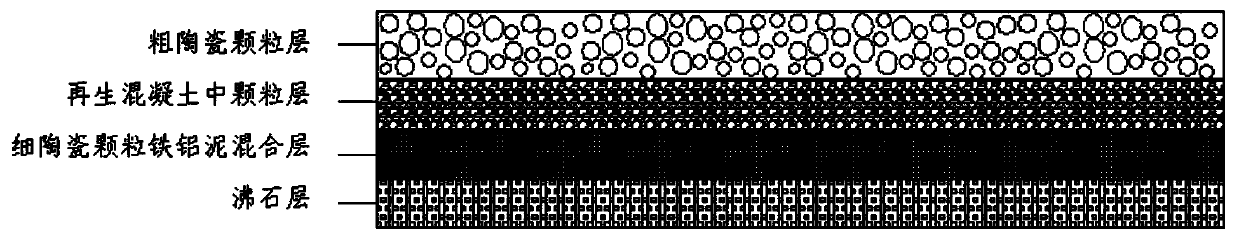

Method used

Image

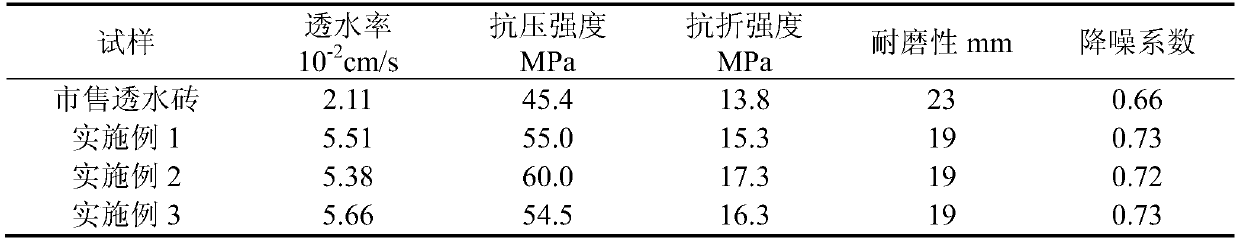

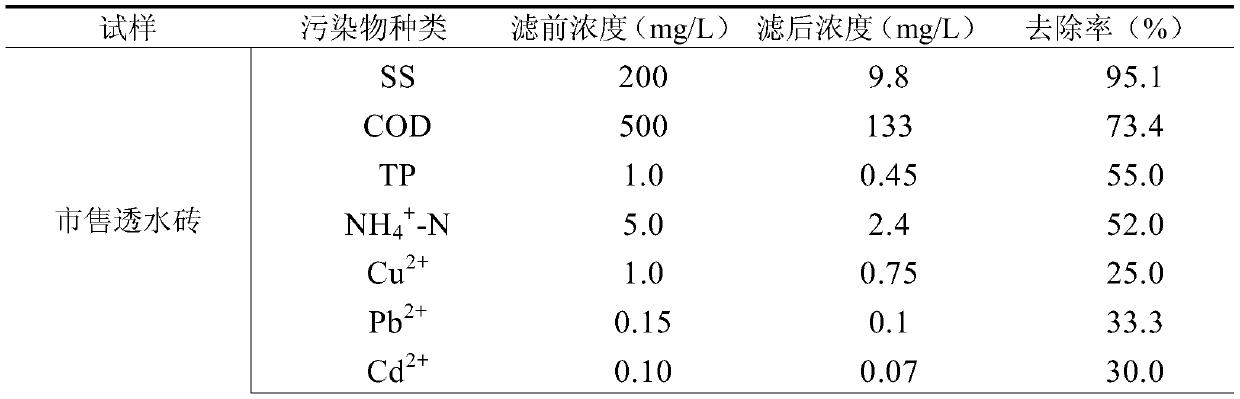

Examples

Embodiment 1

[0041] A method for preparing a permeable brick capable of removing various pollutants, the steps of which are as follows:

[0042] 1) Raw materials are weighed in proportion, 35% of discarded ordinary electromagnetic ceramic tiles, 30% of recycled concrete, 18% of clinoptilolite, 7% of sintering aids, and 10% of iron-aluminum mud for later use;

[0043] 2) Crushing and sieving 65% of the total weight of waste ceramic tiles so that the particle size is less than 1.5mm accounts for more than 90%, take the sieve material and remove the large edges and corners by ball milling, and then mix it with sintering aids to obtain coarse ceramic particle layer raw materials ;

[0044] 3) Continue to crush the remaining materials from the above sieving and the remaining waste ceramic bricks until the particles with a particle size of 0.3-0.5mm account for more than 80%, and then mix them with iron-aluminum mud and sintering aids to obtain a mixed layer of fine ceramic particles iron-alumin...

Embodiment 2

[0049] A method for preparing a permeable brick capable of removing various pollutants, the steps of which are as follows:

[0050] 1) Raw materials are weighed in proportion, 35% of discarded magnesia ceramic bricks, 30% of recycled concrete, 18% of clinoptilolite, 7% of sintering aids, and 10% of iron-aluminum mud for later use;

[0051] 2) Crushing and sieving 65% of the total weight of waste ceramic tiles so that the particle size is less than 1.5mm accounts for more than 90%, take the sieve material and remove the large edges and corners by ball milling, and then mix it with sintering aids to obtain coarse ceramic particle layer raw materials ;

[0052] 3) Continue to crush the remaining materials from the above sieving and the remaining waste ceramic bricks until the particles with a particle size of 0.3-0.5mm account for more than 80%, and then mix them with iron-aluminum mud and sintering aids to obtain a mixed layer of fine ceramic particles iron-aluminum mud raw mat...

Embodiment 3

[0057] A method for preparing a permeable brick capable of removing various pollutants, the steps of which are as follows:

[0058] 1) Raw materials are weighed in proportion, 35% of discarded magnesia ceramic bricks, 30% of recycled concrete, 18% of clinoptilolite, 7% of sintering aids, and 10% of iron-aluminum mud for later use;

[0059] 2) Crushing and sieving 65% of the total weight of waste ceramic tiles so that the particle size is less than 1.5mm accounts for more than 90%, take the sieve material and remove the large edges and corners by ball milling, and then mix it with sintering aids to obtain coarse ceramic particle layer raw materials ;

[0060] 3) Continue to crush the remaining materials from the above sieving and the remaining waste ceramic bricks until the particles with a particle size of 0.3-0.5mm account for more than 80%, and then mix them with iron-aluminum mud and sintering aids to obtain a mixed layer of fine ceramic particles iron-aluminum mud raw mat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com