Real ship inspection method for container ship binding system

A container ship and inspection method technology, which is applied to ship parts, ship construction, ship design, etc., can solve the problems of increased construction costs, time and energy consumption, and long time occupation of dock cranes in shipyards, and achieve the effect of ensuring reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

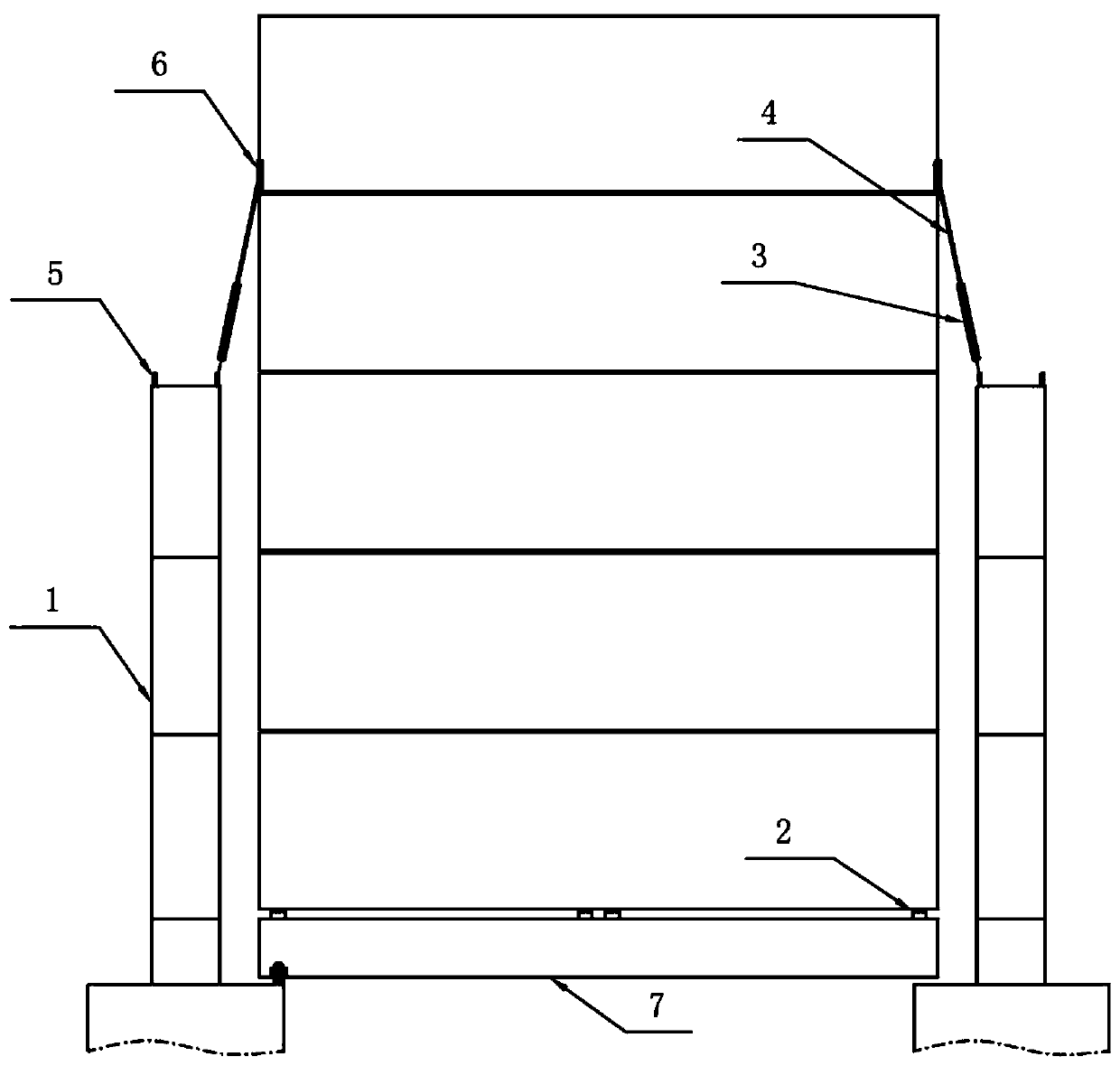

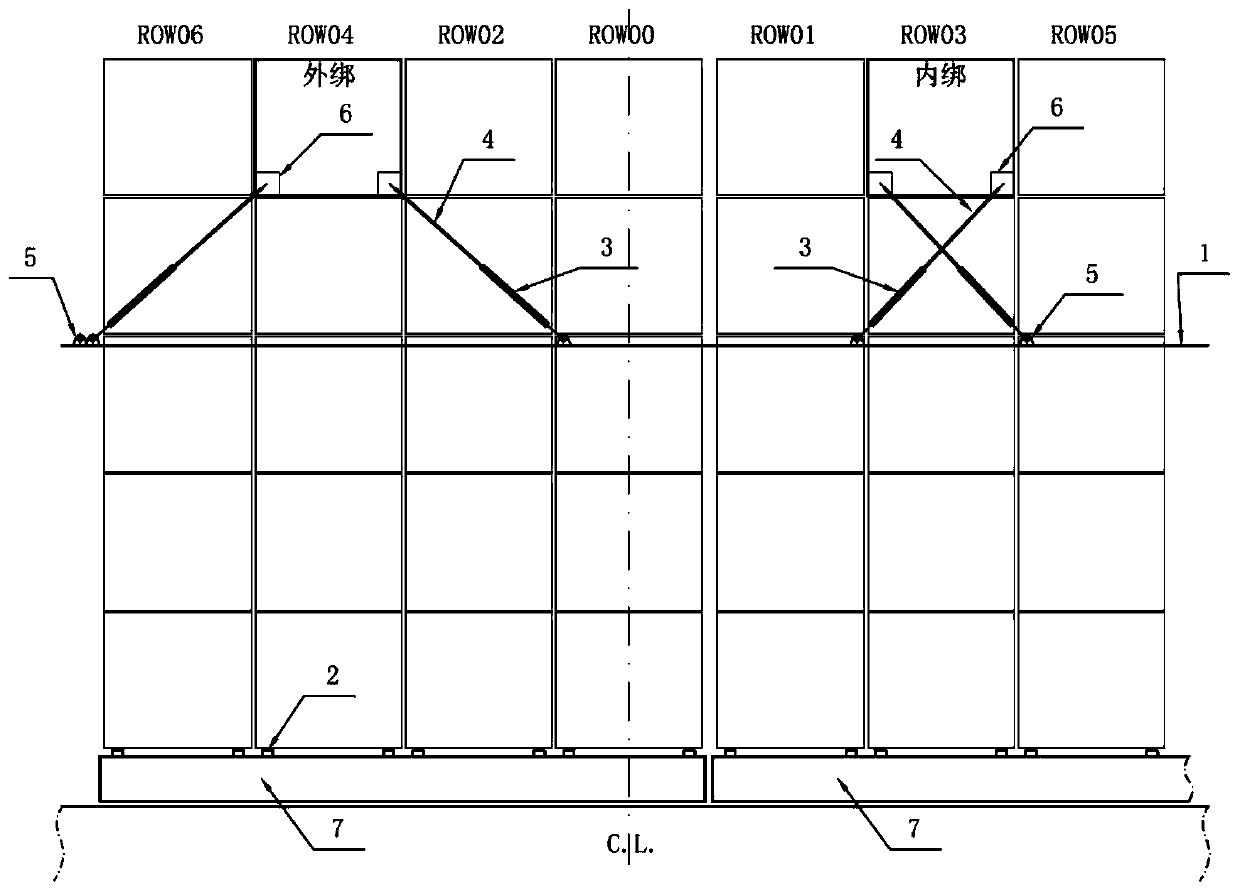

[0027] see Figure 1-Figure 2 , a real ship inspection method for a container ship lashing system, comprising the following steps:

[0028] S1. Establish a three-dimensional model of the binding system;

[0029] S2. Calculate the theoretical binding length through the binding model;

[0030] S3, calculating the actual lashing length of the real ship;

[0031] S4. Using the theoretical binding length and the actual binding length, calculate the change value of the binding length;

[0032] S5. Calculating the final margin of the turnbuckle: measure the original margin value of the turnbuckle in the model, and consider the change value of the binding length, then the final margin value of the turnbuckle after the error can be obtained;

[0033] S6. According to the judgment standard, it is judged whether the final margin value of the turnbuckle meets the requirements, and guidance on the adjustment direction and value is given to the binding eye plates that do not meet the req...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com