Wire rope sleeve ring with sheath

A technology of sheaths and collars, applied in the direction of belts/chains/gears, transmission elements or pulleys, ropes or cables, textile cables, etc., can solve problems such as single function and unstable shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below in conjunction with specific embodiment, content of the present invention is described in further detail:

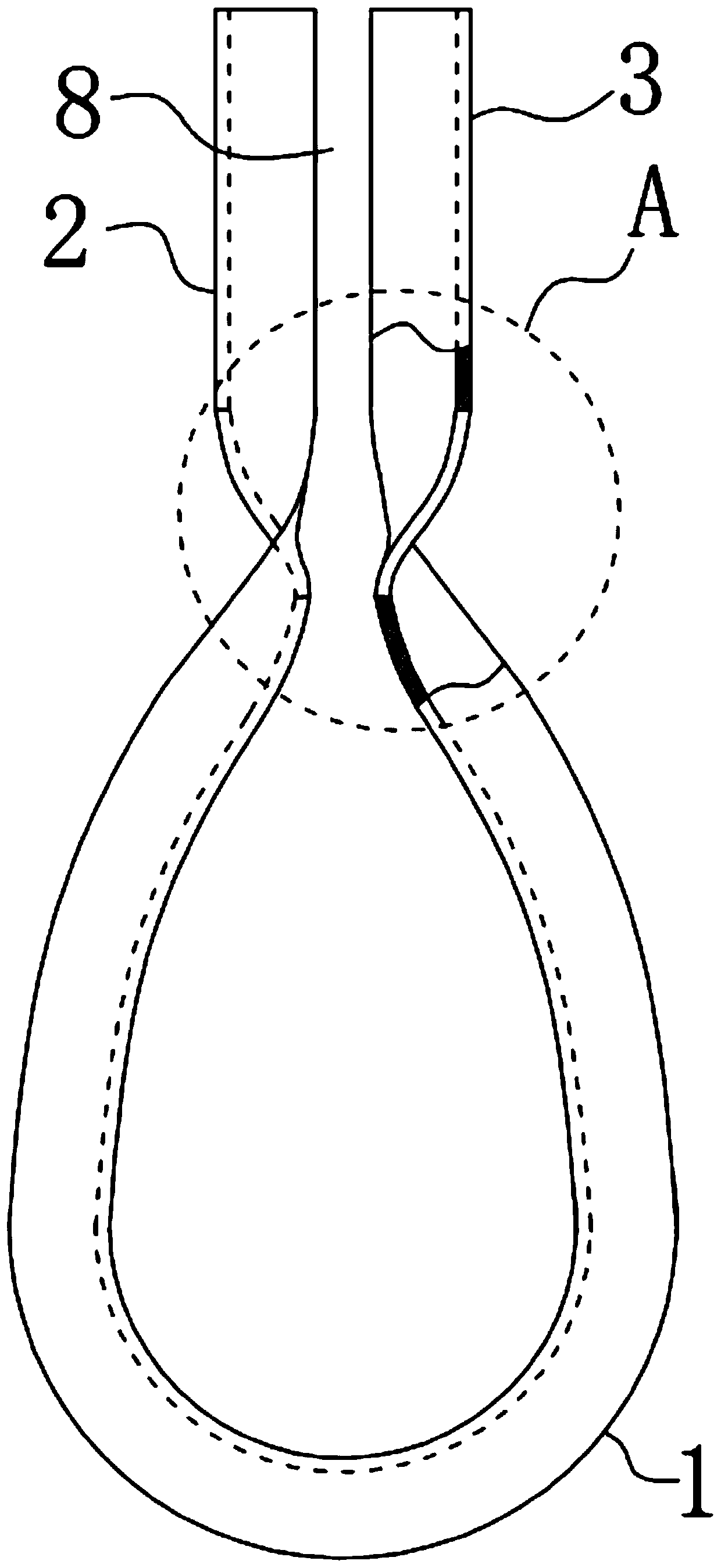

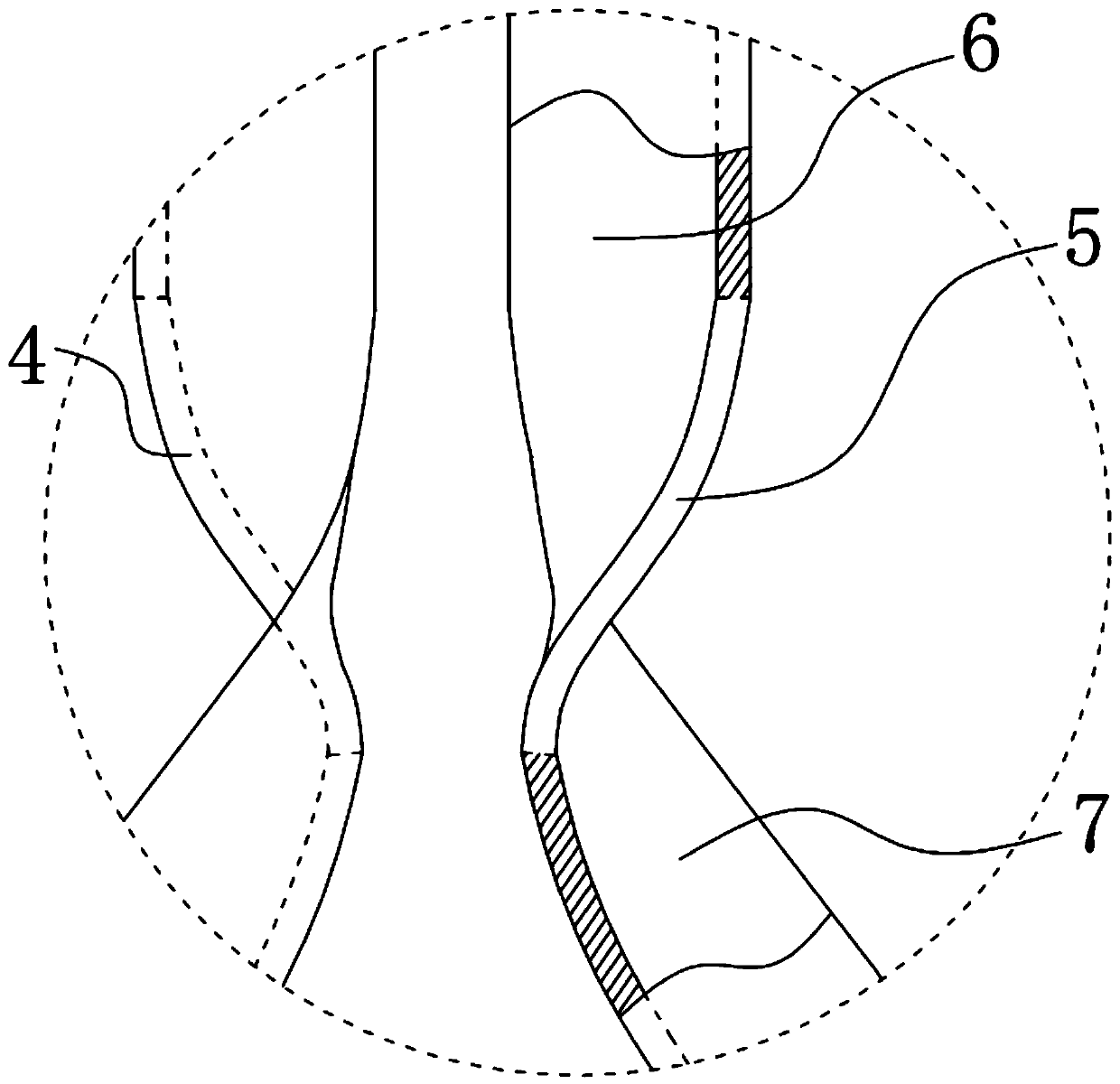

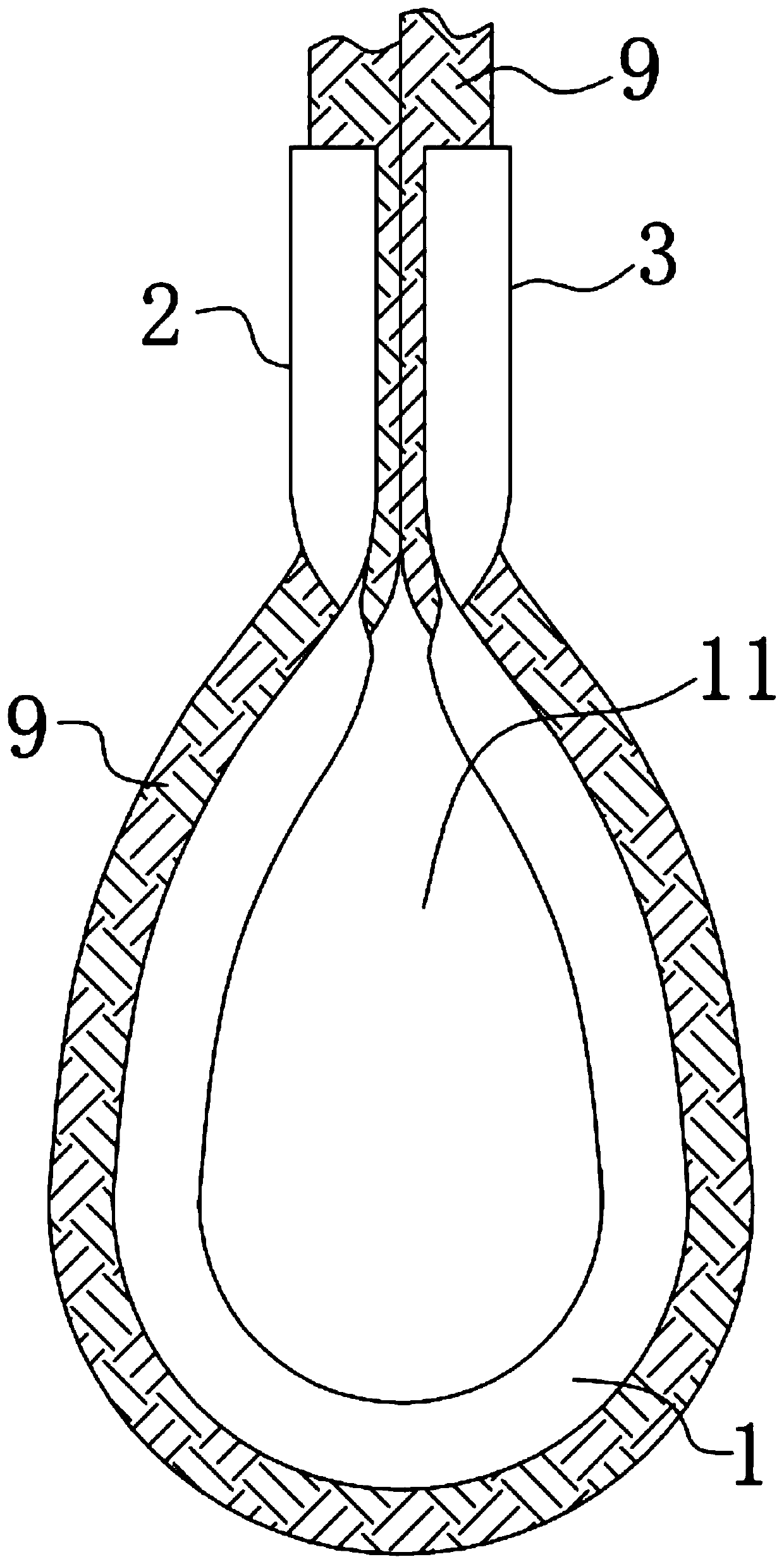

[0028] In order to achieve the purpose of the present invention, a steel rope collar with a sheath includes: a collar section 1, which is concave and curved, and the collar section 1 encloses a through cavity 11, and the collar section 1 has a steel rope. The lower recessed groove 7 of 9, the concave surface of the lower recessed groove 7 faces outward; the sheath section includes the first sheath section 2, the second sheath section 3 connected to the two ends of the collar section 1, and the first sheath section 2. The second sheath section 3 is located above the collar section 1 and is vertically parallel to each other. The mutually facing surfaces of the first sheath section 2 and the second sheath section 3 are equipped with an upper concave groove 6 for accommodating the steel rope 9; holes , for the steel rope 9 to pass through, the hole includes the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com