Method for completing rolling coating by combining automatic spray gun and roller

An automatic spray gun and roller technology, which is applied in the direction of construction and building construction, can solve the problems of poor consistency and unevenness of spraying and rolling, and achieve the effect of easy automatic construction and use, good uniformity and strong applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The orientation shown in the drawings should not be construed as limiting the specific protection scope of the present invention, but only for reference and understanding of preferred embodiments, and the product components shown in the drawings can be changed in position, increased in number or simplified in structure.

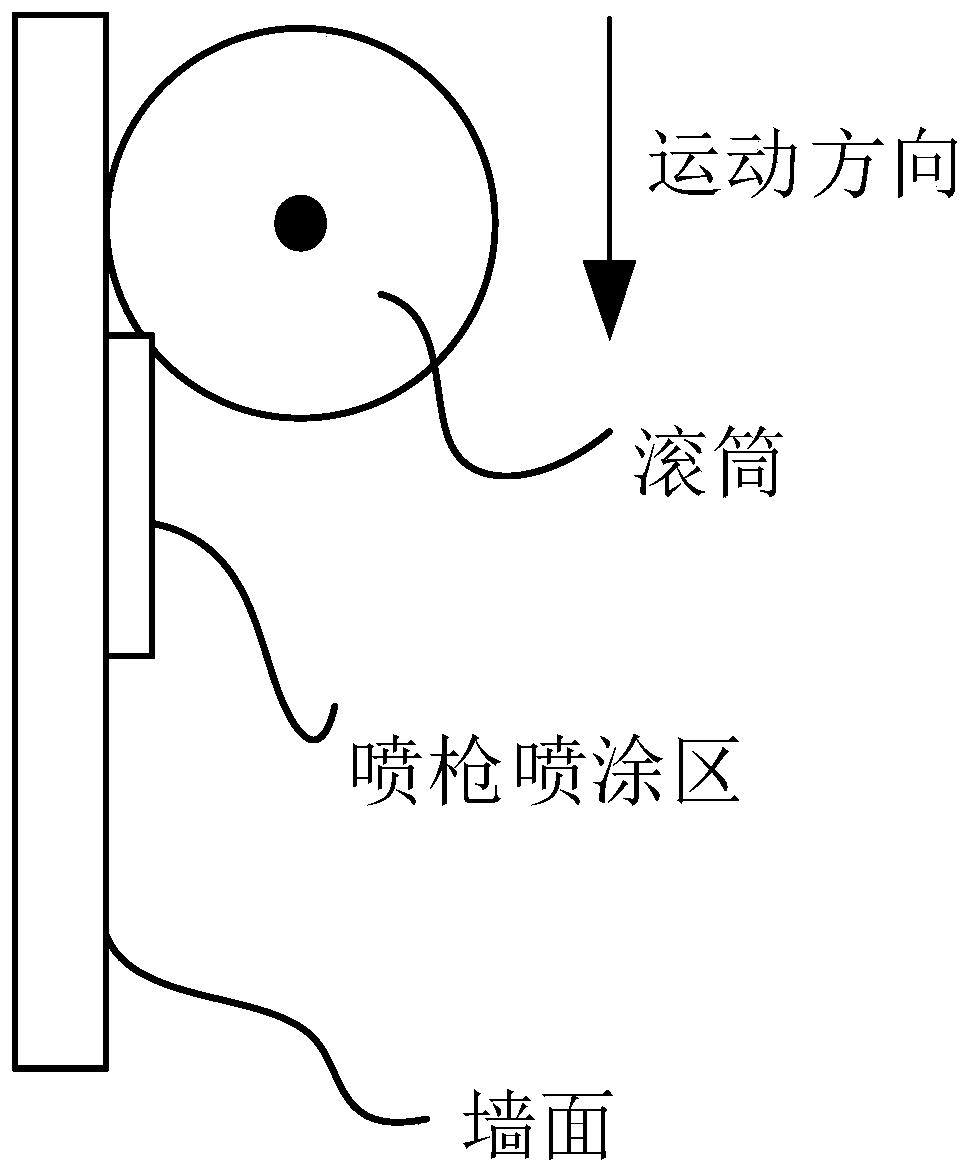

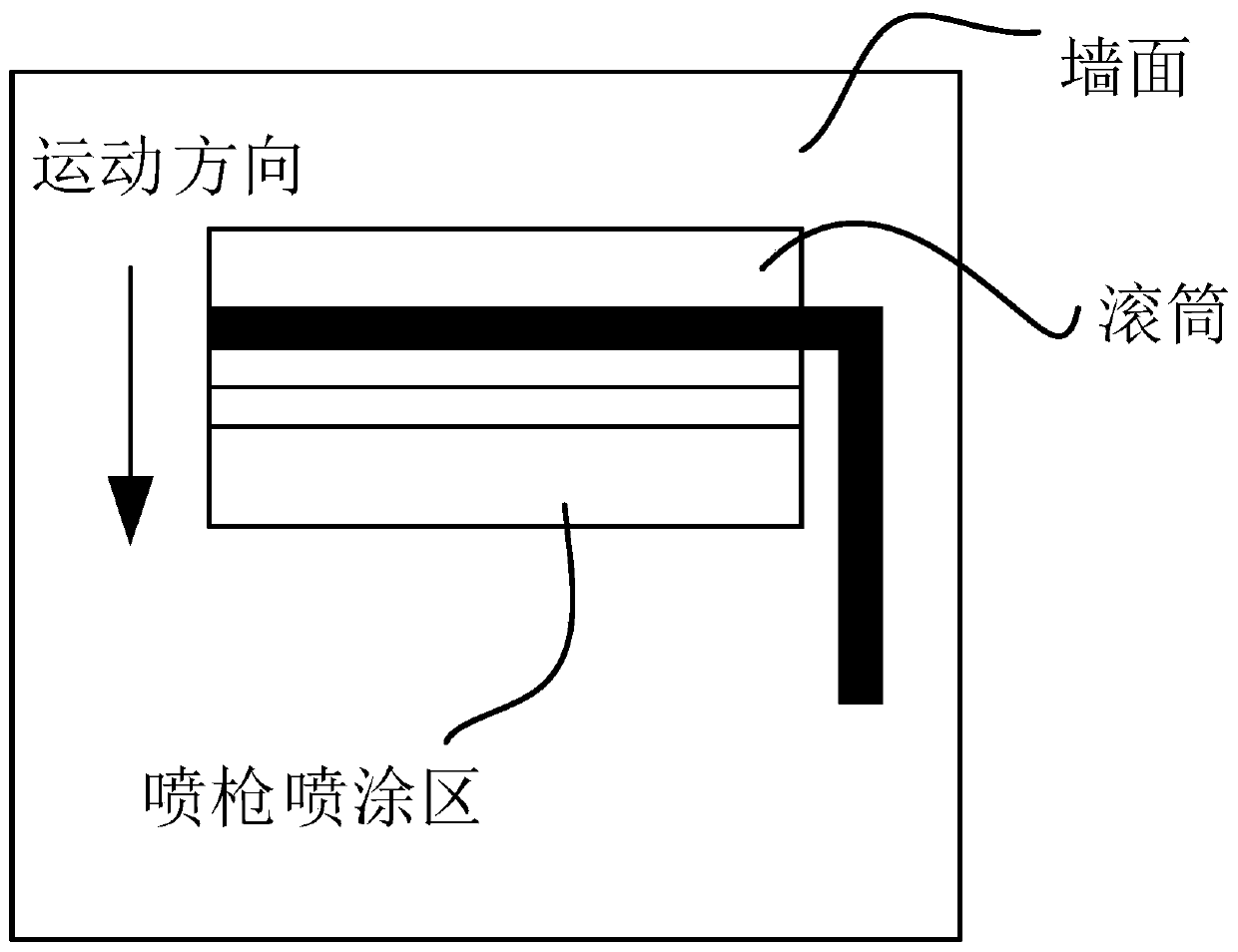

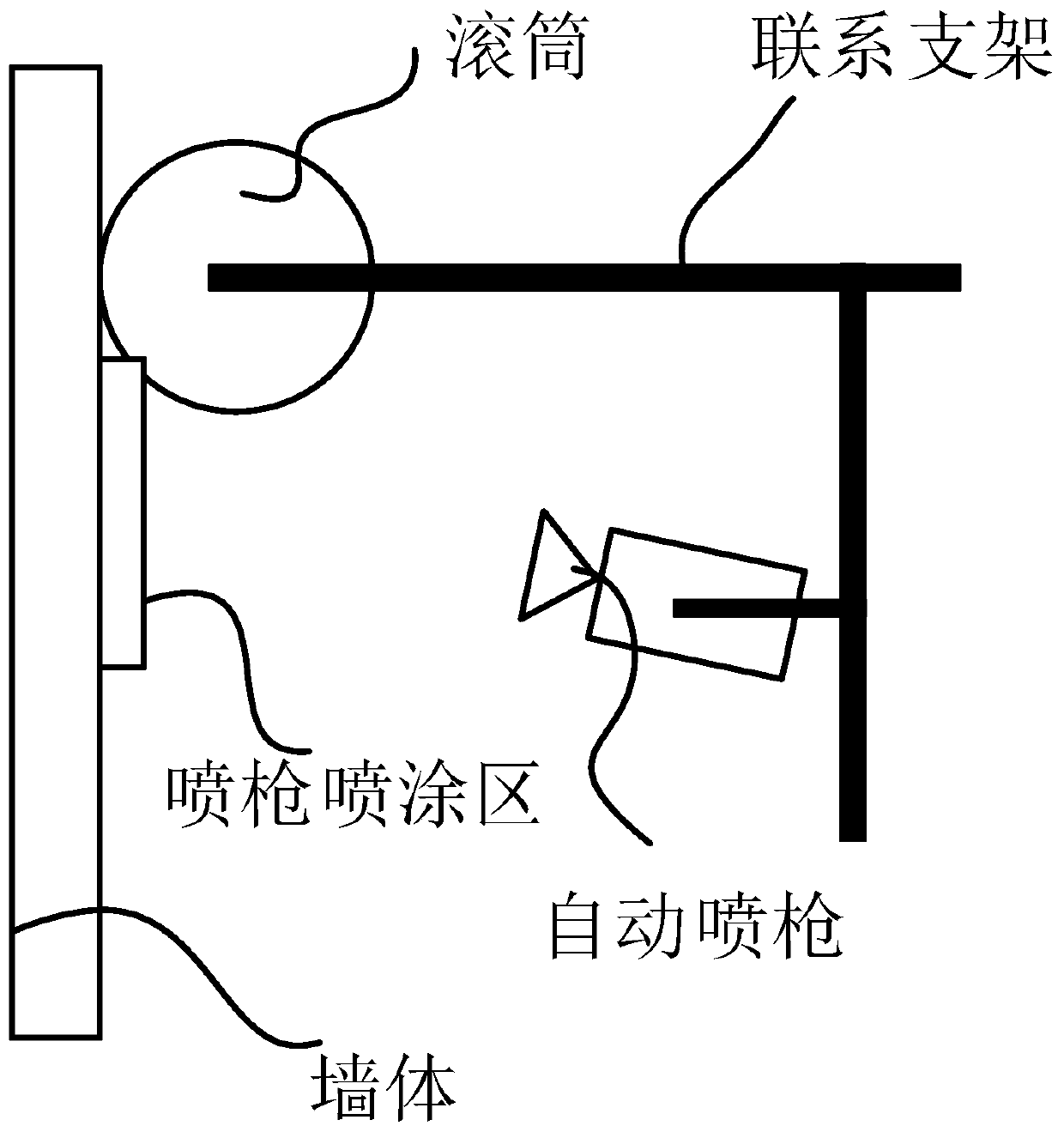

[0017] Figure 1-3 Shown in, provided a kind of preferred embodiment is a kind of rolling coating method that the combination of automatic spray gun and roller completes operation, provides sensor, roller, automatic spray gun and connection support, and described roller is installed on The front end of the contact bracket is connected with the automatic spray gun. After the automatic spray gun sprays the wall, the roller moves along the direction of the spray area to form roll coating on the wall surface.

[0018] Further, the automatic spray gun is set lower than the drum, so that the spraying area is located below the drum, and the spraying movement ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com