Pavement structure using super-viscous fiber wearing layer

A wear-resistant layer and fiber technology, which is applied to cohesive pavement paved on site, roads, roads, etc., can solve the problems of too deep base structure strength and defect depth, poor skid resistance and low durability of asphalt pavement, and achieve The effect of prolonging the life of the pavement, improving the life, strong bending resistance and rebound recovery ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

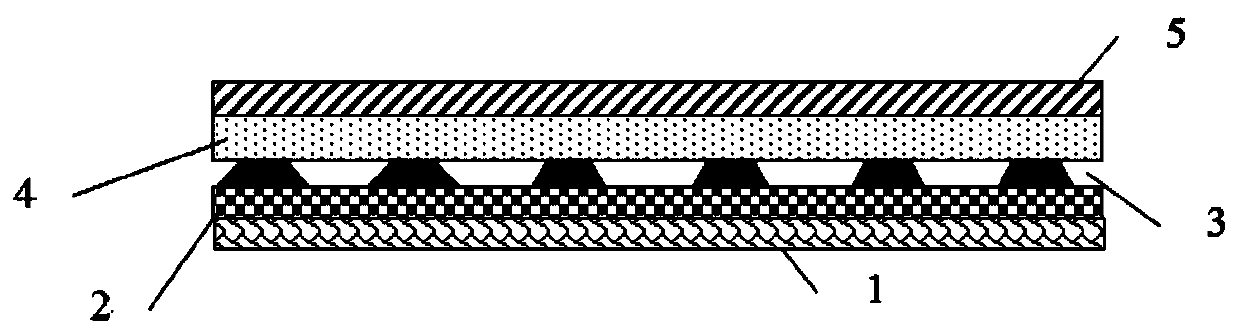

[0020] A pavement structure using a super viscous fiber wear layer, comprising from bottom to top: a base layer 1 with compacted strength, a highly permeable emulsified asphalt oil permeable layer 2 with a thickness of at least 3 mm, a structural reinforcement layer 3, and a modified emulsified asphalt viscous oil layer 4 And a super viscous fiber wearing layer 5 containing untwisted roving glass fiber.

[0021] The thickness of the structural reinforcing layer 3 comprising reinforcing ribs arranged in parallel is at least 5 mm. The reinforcing ribs are fixed by the fixing groove at the bottom or at least two transverse ribs crossing in the vertical direction to prevent movement of the position under pressure when the aggregate is filled. The reinforcement rib in this embodiment is a hollow circular tube type reinforcement rib. The structural reinforcement layer is divided into upper and lower layers by the horizontal diameter plane of the hollow circular tube reinforcing rib...

Embodiment 2

[0025] Such as figure 1 As shown in , a pavement structure using a super viscous fiber wear layer, including from bottom to top: a base layer of compacted strength 1, a highly permeable emulsified asphalt oil-permeable layer with a thickness of at least 3mm 2, a structural reinforcement layer 3, and a modified emulsified Asphalt viscous oil layer 4 and super viscous fiber wearing layer 5 containing roving glass fiber.

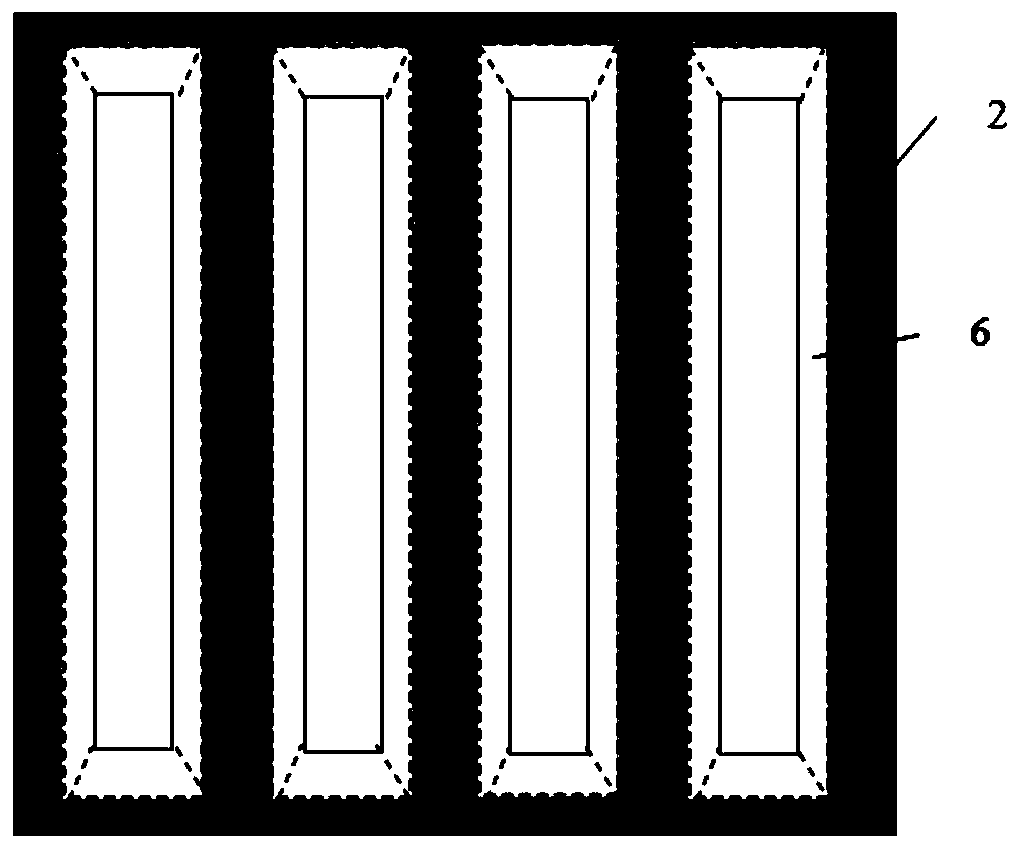

[0026] The structural reinforcement layer 3 has a thickness of at least 5 mm. The reinforcement ribs are arranged in parallel, and the reinforcement ribs are fixed by a fixed groove at the bottom or at least two transverse ribs vertically crossing to prevent movement of the position under pressure when the aggregate is filled. Such as figure 1 and 2 As shown in , the reinforcement rib in this embodiment is a sleeper type reinforcement rib 6 with a trapezoidal cross section. The lower included angle of the trapezoidal cross-section of the cross-section of th...

Embodiment 3

[0031] A pavement structure using a super viscous fiber wear layer, comprising from bottom to top: a base layer 1 with compacted strength, a highly permeable emulsified asphalt oil permeable layer 2 with a thickness of at least 3 mm, a structural reinforcement layer 3, and a modified emulsified asphalt viscous oil layer 4 And a super viscous fiber wearing layer 5 containing untwisted roving glass fiber.

[0032] The structural reinforcement layer 3 includes at least two layers, one of which uses hollow circular tube-type reinforcing ribs, and the other layer uses sleeper-type reinforcing ribs. The hollow circular tube-type reinforcing ribs and sleeper-type reinforcing ribs of adjacent layers are arranged in a criss-cross pattern and stacked.

[0033] The hollow round tube has stronger bending resistance and rebound recovery ability than the solid round tube, and the sleeper-shaped reinforcing rib can disperse the pressure, reduce the impact on the lower layer, further avoid sa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com