Tower crane moving passage system

A tower crane and aisle technology, which is applied in the direction of housing structure support, housing structure support, scaffolding supported by housing structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings and preferred embodiments.

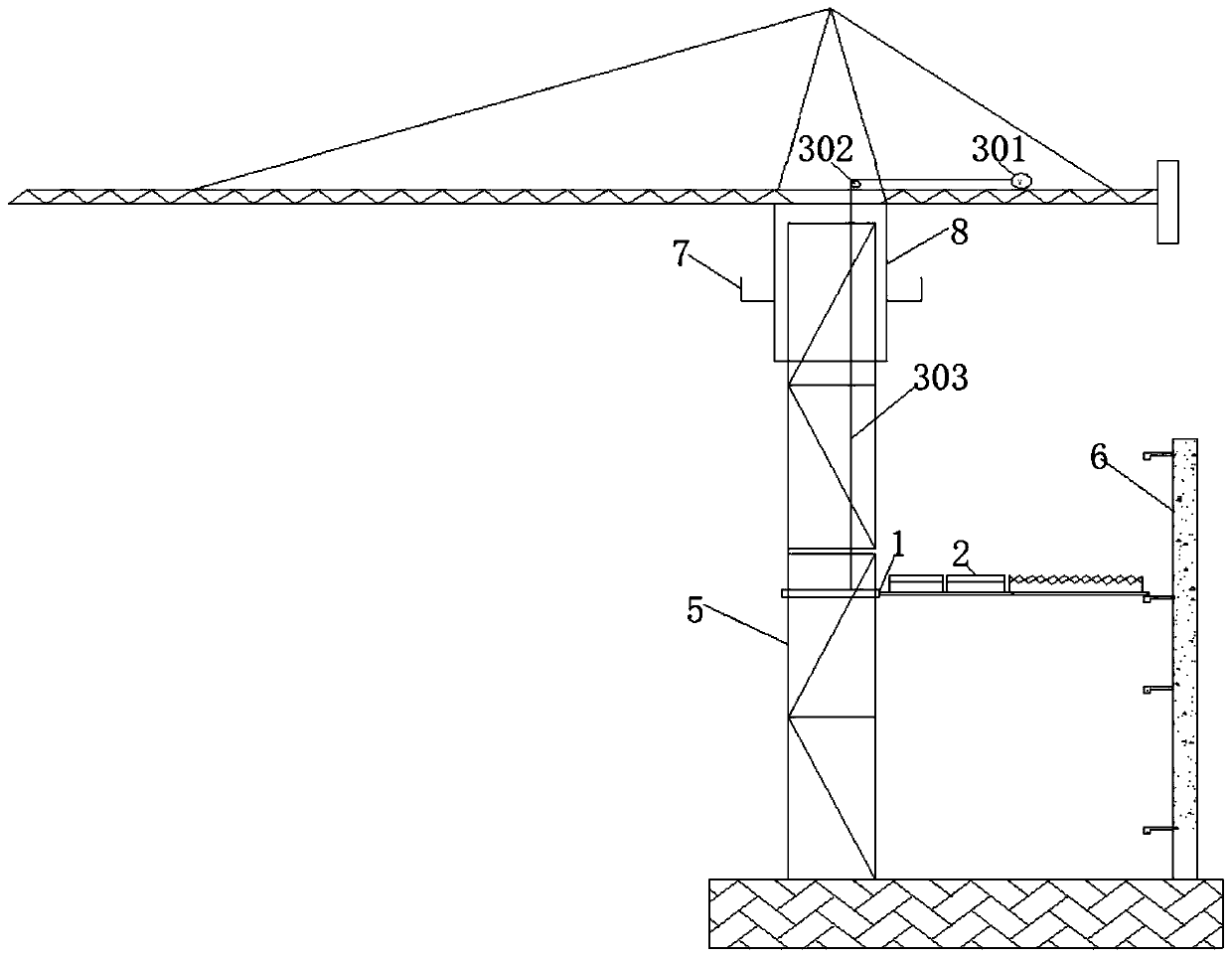

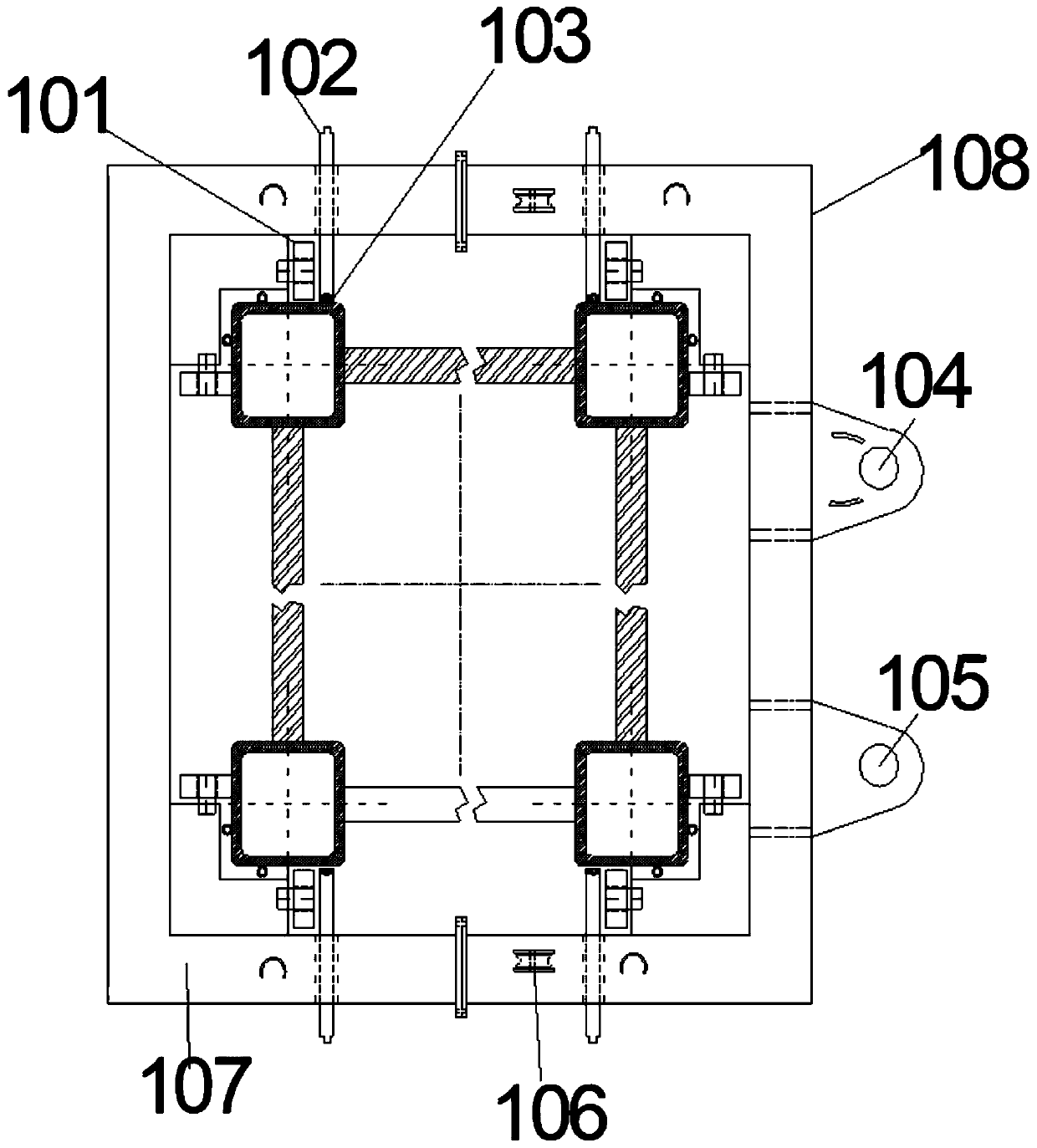

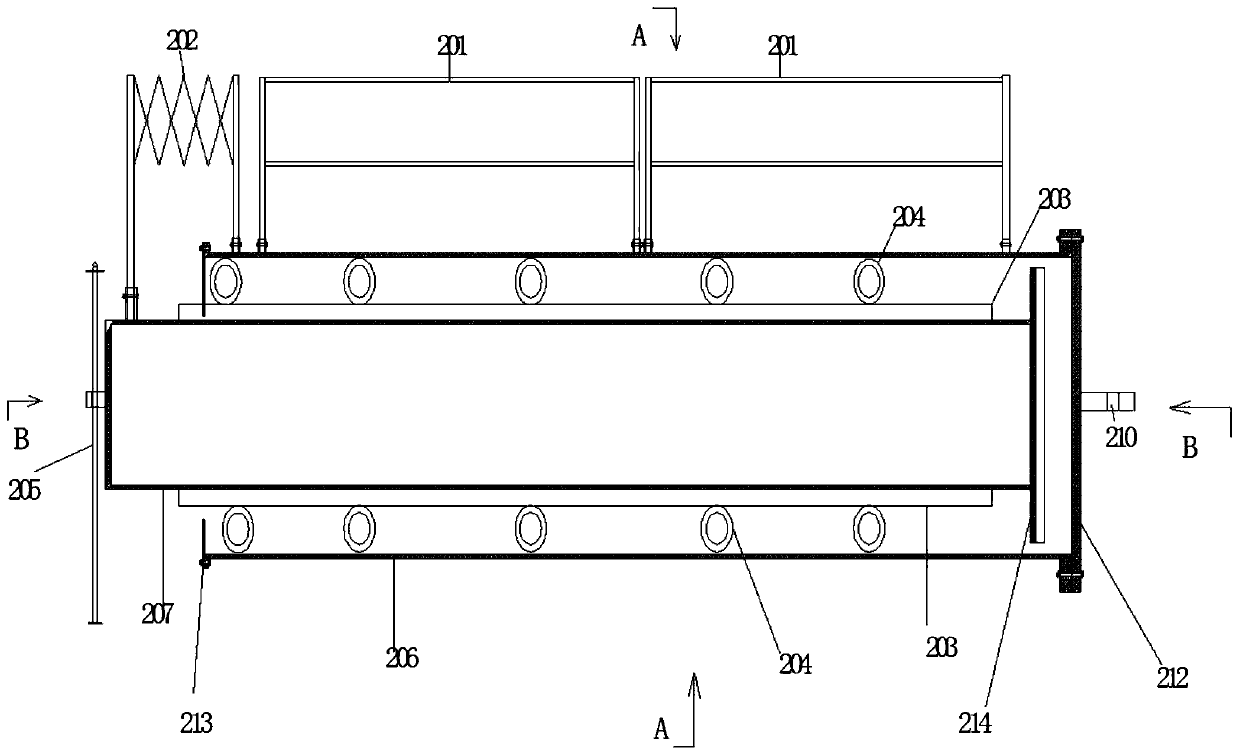

[0034] Such as Figure 1 to Figure 5 As shown, a tower crane movable aisle system includes a lifting frame 1, a lifting device 3, a telescopic platform 2 and a telescopic device 4; The guide wheels 101 for lifting the standard section 5 of the tower crane (the guide wheels 101 are distributed on both sides of the four corners of the standard section 5 of the tower crane, avoiding the position where the standard section 5 of the tower crane is connected to the bolt casing) and the ejector rod for locking the height of the lifting frame 1 102 (when the lifting frame 1 is locked, the ejector rod 102 tightens the tower crane standard section 5 from both sides, and the head of the ejector rod 102 can be provided with anti-skid rubber 103 to prevent the metal surface from being damaged by the surface protection layer of the tower crane standard sect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com