Automatic rubber material gluing robot and detecting equipment

A technology of rubber materials and robots, which is applied in the direction of manipulators, program-controlled manipulators, chucks, etc., can solve the problems of inability to monitor the compaction status in real time, low gluing efficiency, and low production efficiency, so as to save material costs, simplify the production process, The effect of improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

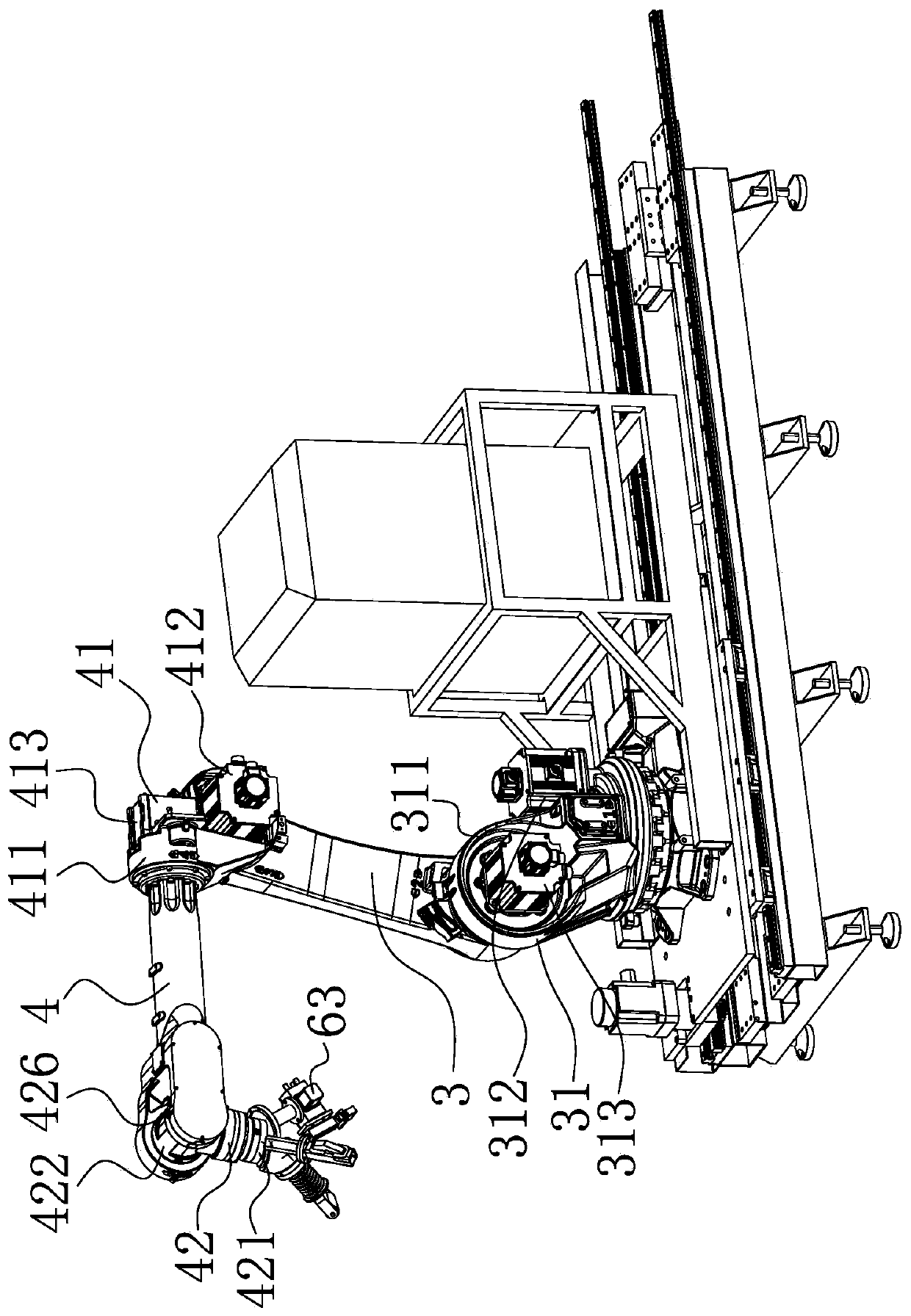

[0026] like Figure 1-5As shown, the rubber material automatic gluing robot includes a sliding track 1 parallel to the worktable 12 and extending along the axial direction of the worktable 12. The sliding track 1 is provided with a mounting seat 2 through a horizontal sliding drive mechanism 11. On the mounting seat 2 A first movable arm 3 is movable, and a first movable arm 3 that can drive the first movable arm 3 to rotate in a circumferential direction and can drive the central axis of the first movable arm 3 to tilt relative to the horizontal direction is provided between the mounting base 2 and the first movable arm 3. A movable drive mechanism 31, the upper end of the first movable arm 3 is movably connected with the second movable arm 4, and there is a device between the first movable arm 3 and the second movable arm 4 that can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com