A Control Method for Improving the Single Weight Consistency of NdFeB Green Body

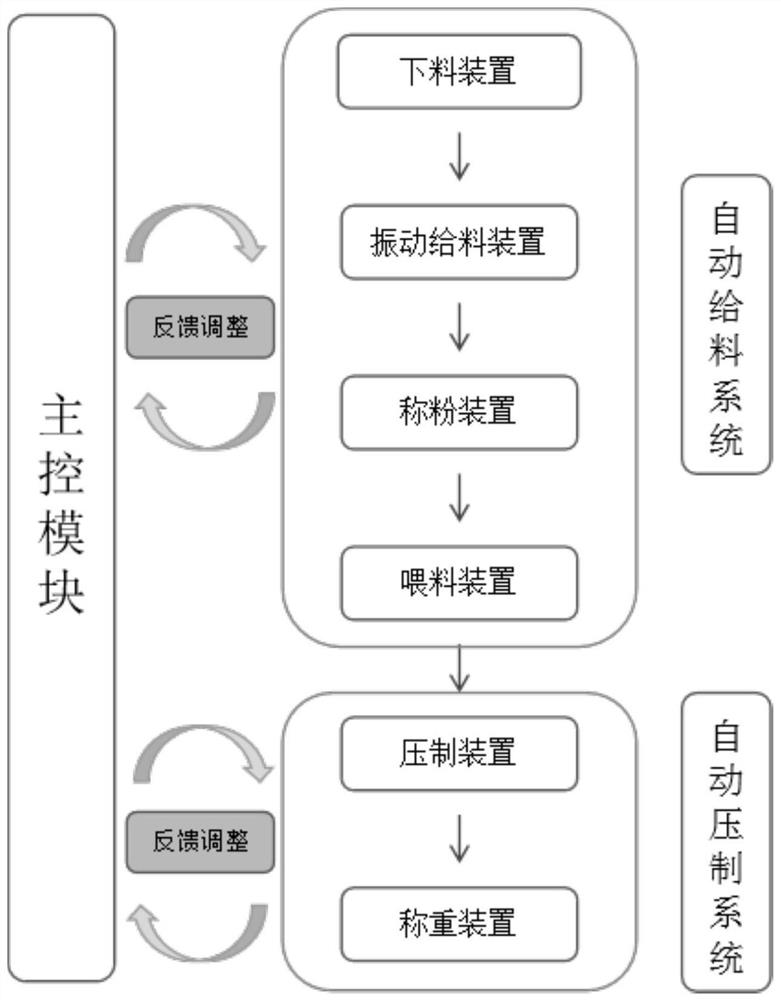

A control method and NdFeB technology, applied in the control field, can solve the problems of powder weight fluctuation, low consistency, large single weight deviation of NdFeB green body, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1: A control method for improving the single weight consistency of NdFeB green body. First, set the upper limit of powder storage in the vibrating feeding device and set the initial parameter value in the main control module, and then under the control of the main control module The feeding device transports the NdFeB powder stored in it to the vibrating feeding device, so that the NdFeB powder in the vibrating feeding device reaches the upper limit of powder storage, and then the main control module controls the vibrating feeding device to enter the feeding stage , in the feeding stage, the vibrating feeding device periodically feeds the feeding device, and the main control module adjusts the vibration of the vibrating feeding device in the next feeding cycle according to the feeding time of the previous feeding cycle and the real-time value of the single-mode powder weight. signal until the amount of NdFeB powder in the feeding device reaches the set value, ...

Embodiment 2

[0030] Embodiment 2: This embodiment is basically the same as the embodiment, and the difference is as follows:

[0031] In this embodiment, the initial parameter values set in the main control module include: the initial vibration signal X of the vibrating feeding device 1 , vibration signal adjustment reference value ΔX, vibration signal adjustment coefficient μ, single-mode powder weight m 1 , powder weight tolerance n 1 , single-mode blanking time preset value T 0 and blanking time trigger signal amplitude T 1 ;Initial vibration signal X 1 It is 1 / 2 of the vibration signal when the vibration feeding device is output at full load, the vibration signal adjustment reference value ΔX is 1% of the vibration signal when the vibration feeding device is output at full load, and the vibration signal adjustment coefficient μ is greater than 0 and less than or equal to 5 Arbitrary constant, single-mode blanking time preset value T 0 Equal to the single-mode cycle time, determi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com