Powder conveying device for curing agent coating production

A powder conveying and curing agent technology, applied in the direction of feeding devices, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of production reaction impact, agglomeration, etc., and achieve the effect of preventing agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

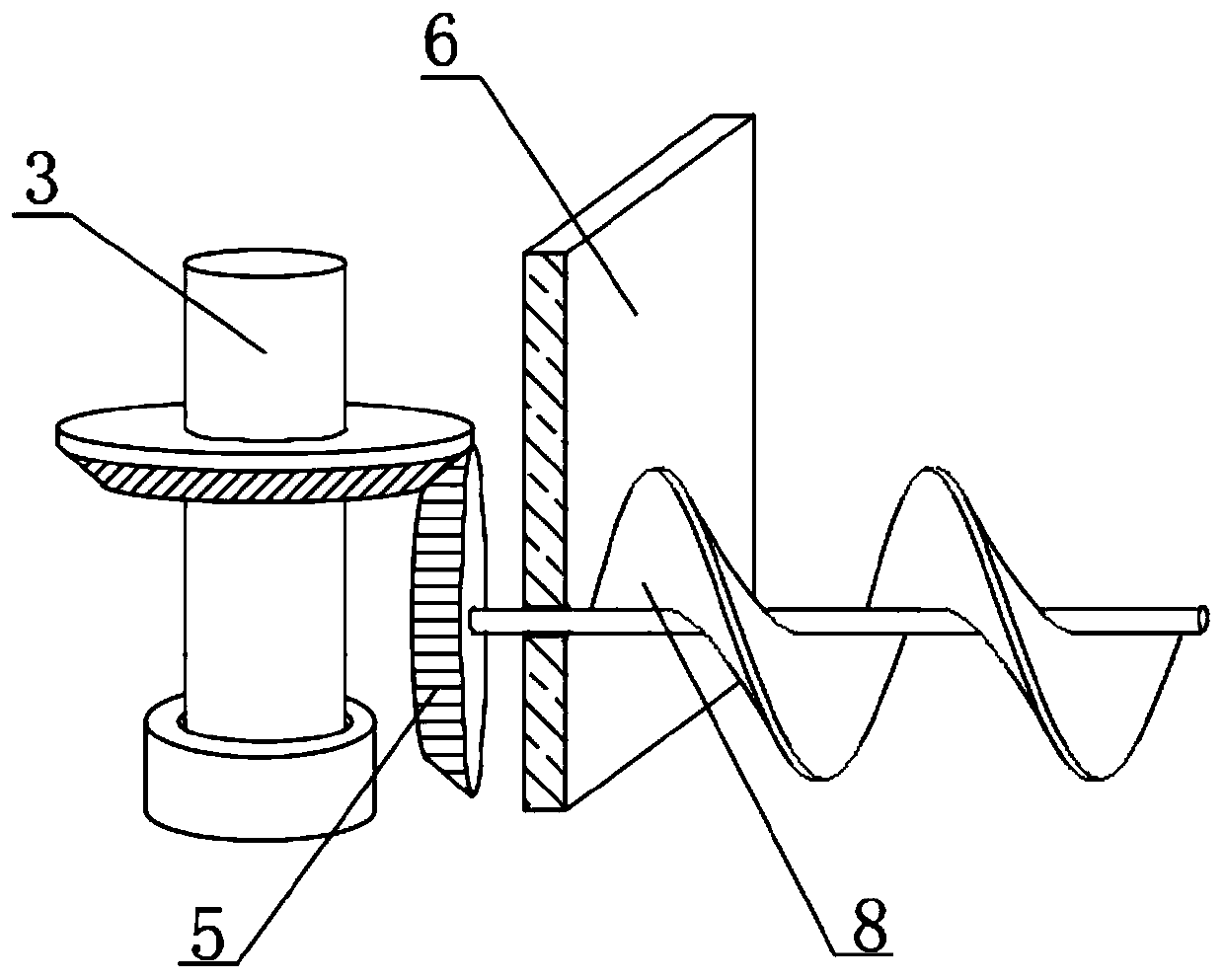

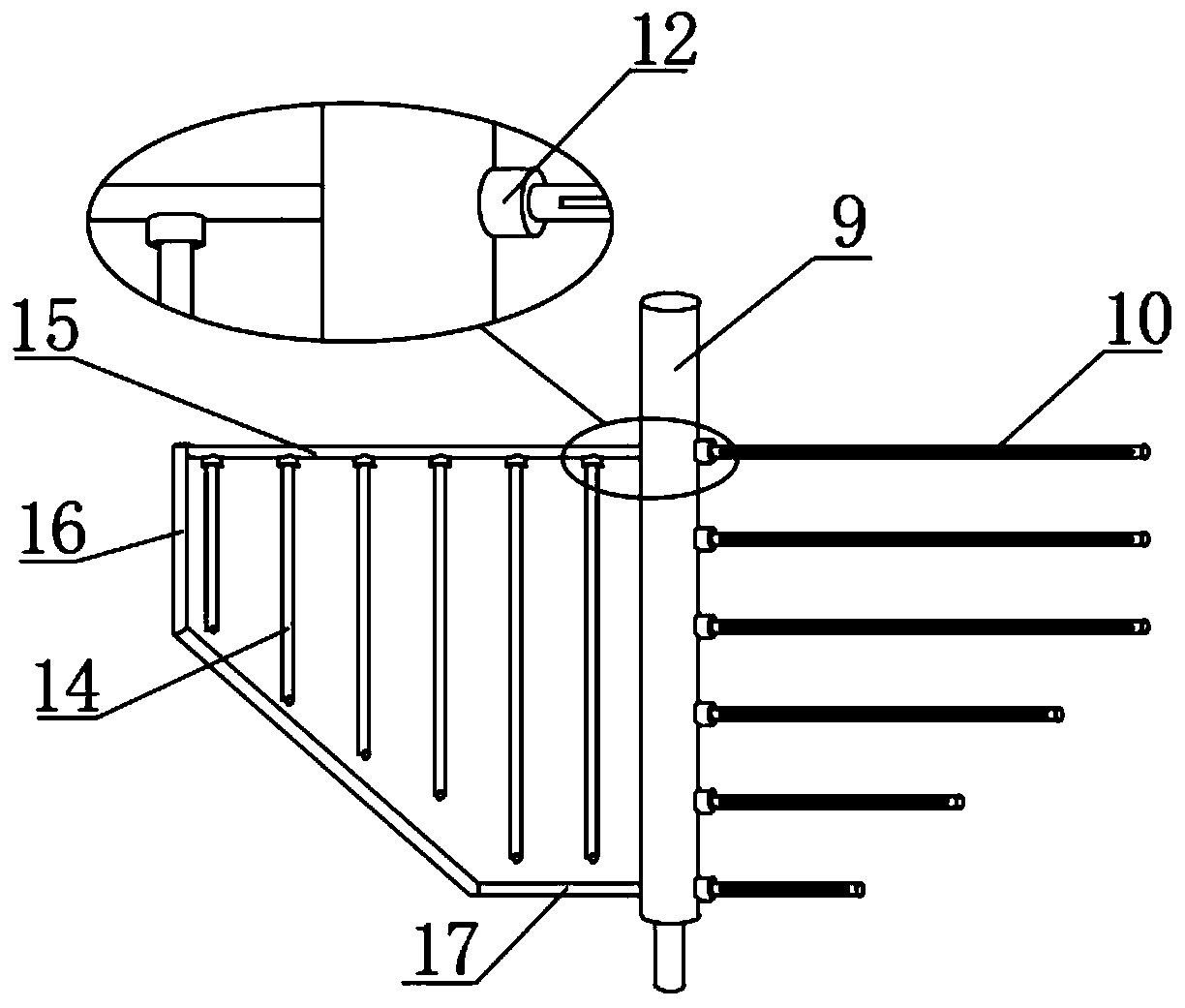

[0027] refer to Figure 1-3 , a powder delivery device for the production of curing agent coatings, including a storage tank 1 with legs welded at the four corners of the bottom. The shaft is connected with the drive rod 9 which is rotationally connected with the storage tank 1, the outer wall of one side of the drive rod 9 is provided with the first stirring rod 10 which is equidistant and horizontally distributed, and the outer wall of the side of the drive rod 9 is far away from the first stirring rod 10 Fixed rod 15 is welded, and the bottom outer wall of fixed rod 15 is provided with the second stirring rod 14 of equidistant vertical distribution, and the opposite side of first stirring rod 10 and drive rod 9 and the second stirring rod 14 and fixed rod 15 The opposite sides of each are welded with an arc-shaped connection block 12, the bottom end of the storage tank 1 is welded with a vertically arranged first delivery section 2, and the first delivery section 2 is welde...

Embodiment 2

[0035] refer to figure 1 and image 3 , a powder conveying device for the production of curing agent coatings. In order to prevent the powder from adhering to the inner wall of the storage tank 1 and causing subsequent inconvenient cleaning, this embodiment also includes a driving rod 9 close to the One side of the fixed rod 15 is welded with a horizontally arranged connecting rod 17, and the ends of the connecting rod 17 and the fixed rod 15 are welded with the same brush rod 16, and the brush rod 16 is adapted to the inner wall of the storage tank 1.

[0036] Working principle: When in use, use the setting of the brush rod 16 to brush the inner wall of the storage tank 1 through the brush rod 16 during the stirring, powder feeding and conveying process, thereby preventing the powder from adhering to the storage tank 1 inner wall.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com