Colored asphalt modification emulsification device

A technology of colored asphalt and emulsification device, which is applied to mixers with rotary stirring devices, transportation and packaging, chemical instruments and methods, etc. problems, to ensure the quality of air emissions, speed up the cutting speed, good mixing and protection effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

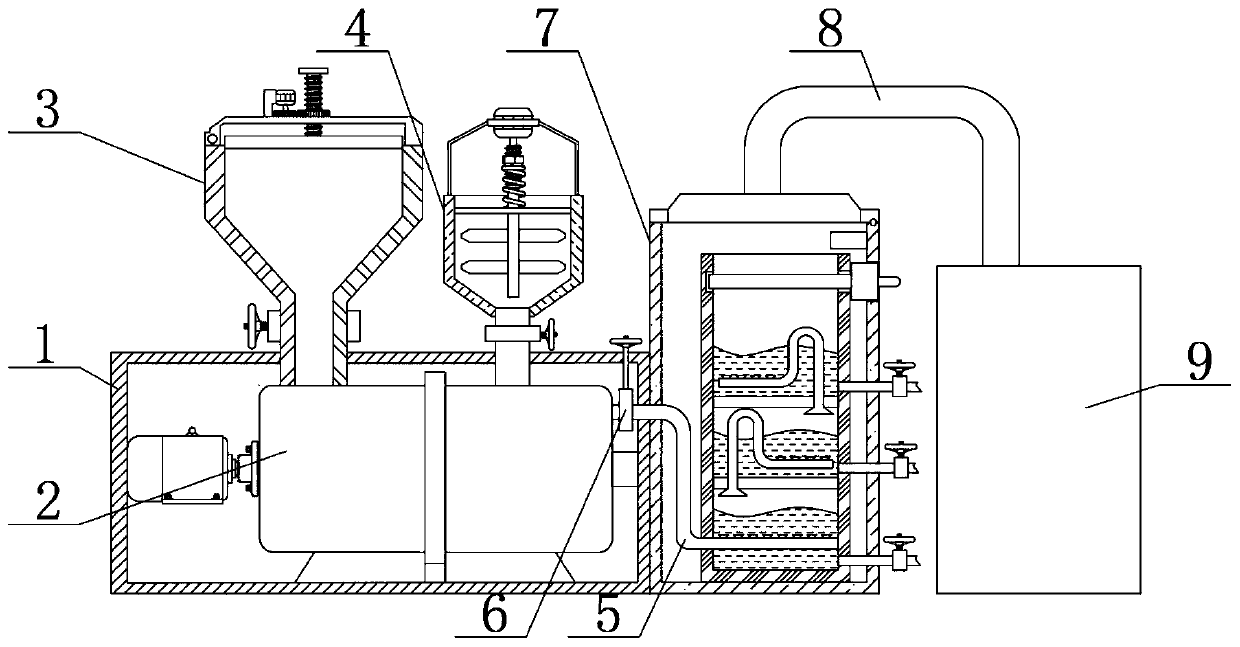

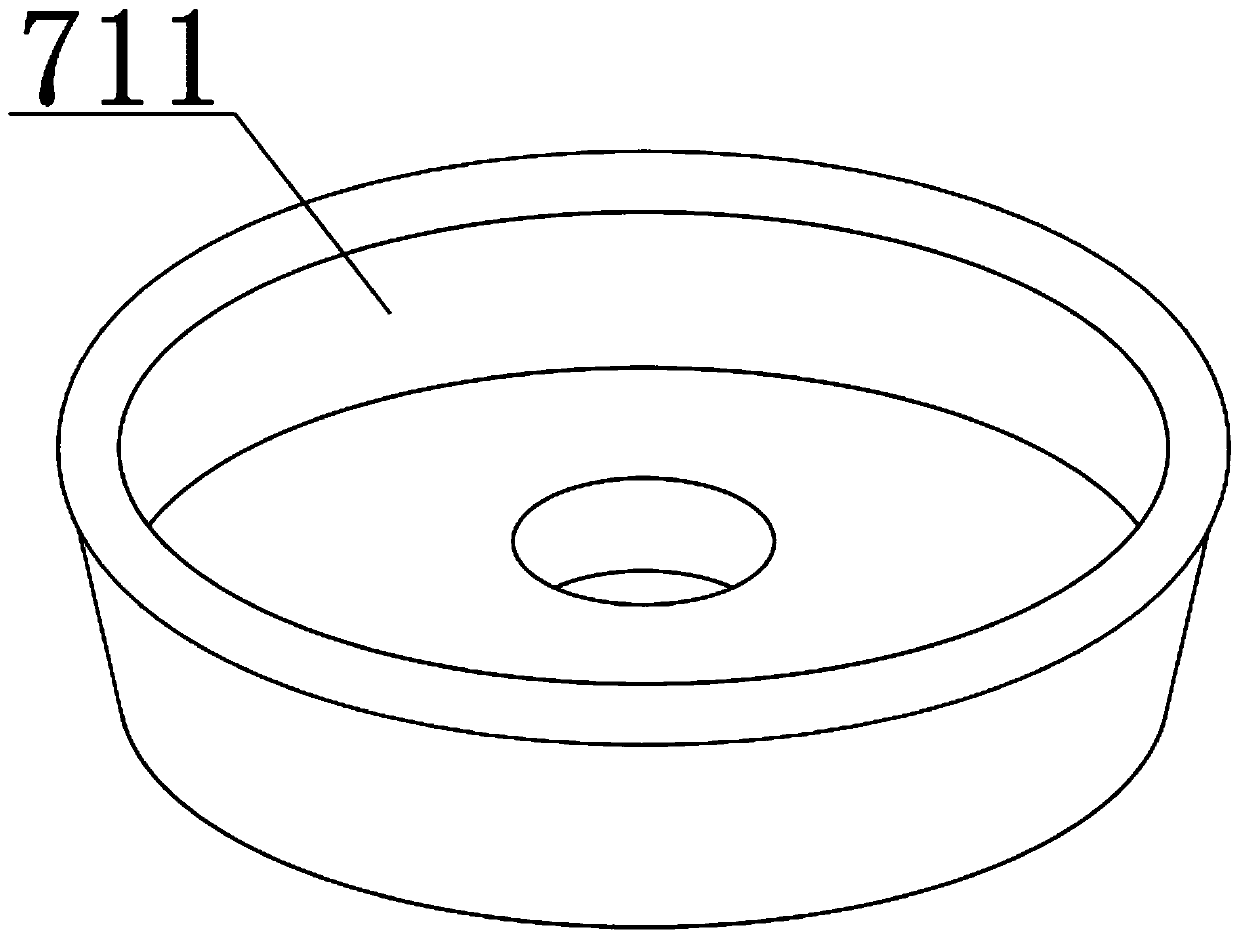

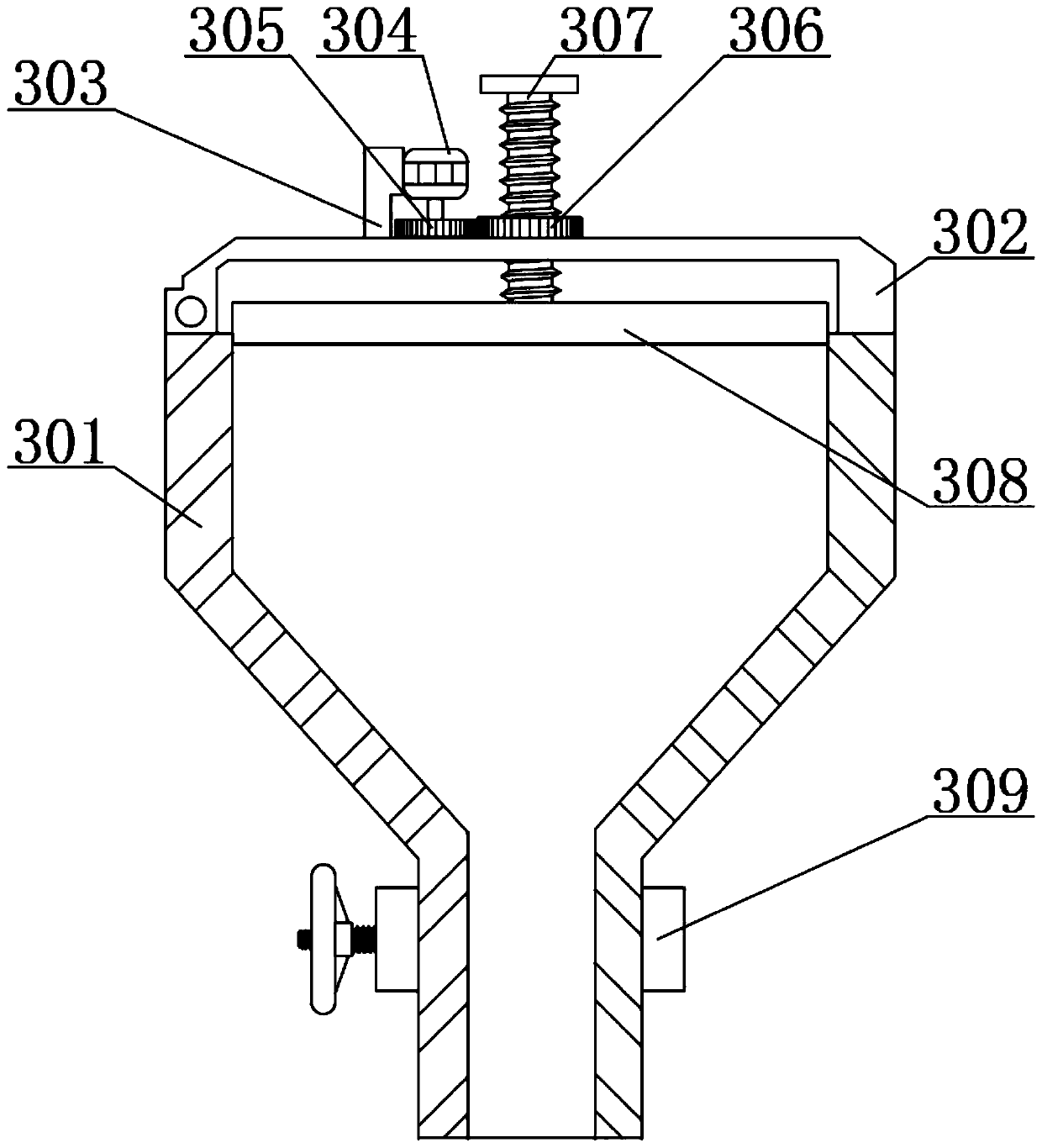

[0025] see figure 1 , figure 2 , image 3 , Figure 4 Figure 5 , the present invention provides a technical solution:

[0026]Colored asphalt modified emulsification device, including base frame 1, emulsifier 2, connecting pipe 8 and air receiver 9, the upper end of base frame 1 is fixedly connected with raw material unloading device 3 and mixing device 4 distributed left and right, raw material unloading The device 3 includes a lower hopper 301, a lower material cover 302, a fixed frame 303 and a rotating motor 304. The lower end of the lower hopper 301 is fixedly connected with the emulsifier 2, and the upper end of the lower hopper 301 is rotatably connected to the left side with a lower material cover 302. The lower material cover The upper end surface of 302 is fixedly connected with a fixed frame 303, the right end surface of the fixed frame 303 is fixedly connected with a rotating motor 304, the end of the main shaft of the rotating motor 304 is fixedly connected ...

Embodiment 2

[0030] see figure 1 , figure 2 , image 3 , Figure 4 Figure 5 , the present invention provides a technical solution:

[0031]Colored asphalt modified emulsification device, including base frame 1, emulsifier 2, connecting pipe 8 and air receiver 9, the upper end of base frame 1 is fixedly connected with raw material unloading device 3 and mixing device 4 distributed left and right, raw material unloading The device 3 includes a lower hopper 301, a lower material cover 302, a fixed frame 303 and a rotating motor 304. The lower end of the lower hopper 301 is fixedly connected with the emulsifier 2, and the upper end of the lower hopper 301 is rotatably connected to the left side with a lower material cover 302. The lower material cover The upper end surface of 302 is fixedly connected with a fixed frame 303, the right end surface of the fixed frame 303 is fixedly connected with a rotating motor 304, the end of the main shaft of the rotating motor 304 is fixedly connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com