Method and device for realizing alternating heating of multiple heating bodies of atomizer

A heating element and atomizer technology, applied in the fields of application, tobacco, food science, etc., can solve the problems of reducing the service life, damaging the elastic properties of the oil-guiding cotton and the ability to store oil, and insufficient oil supply.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

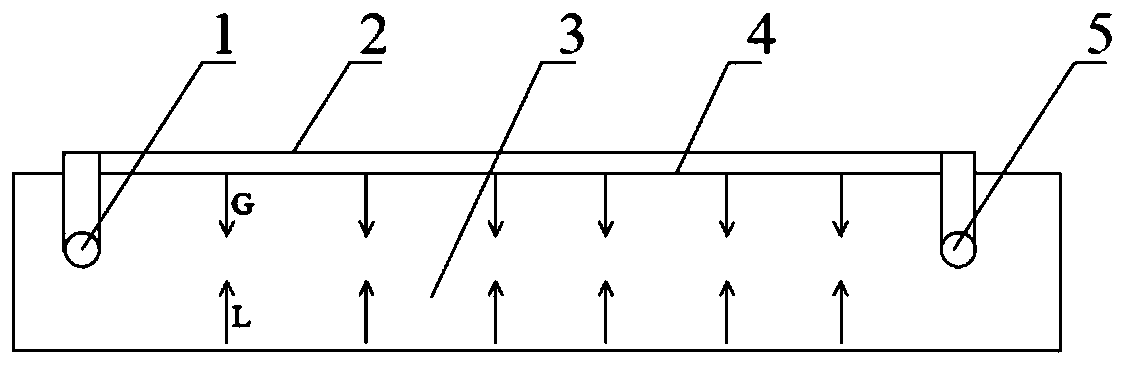

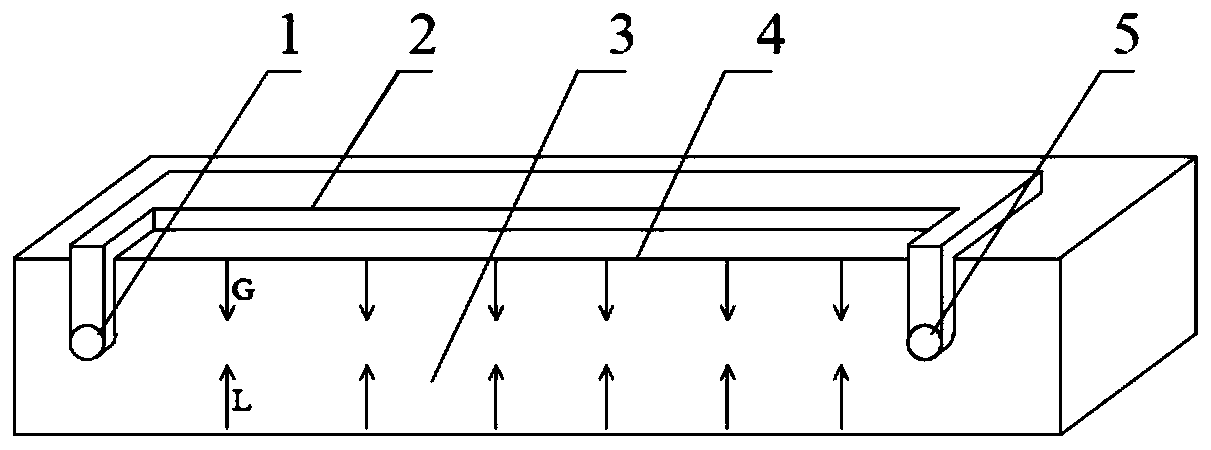

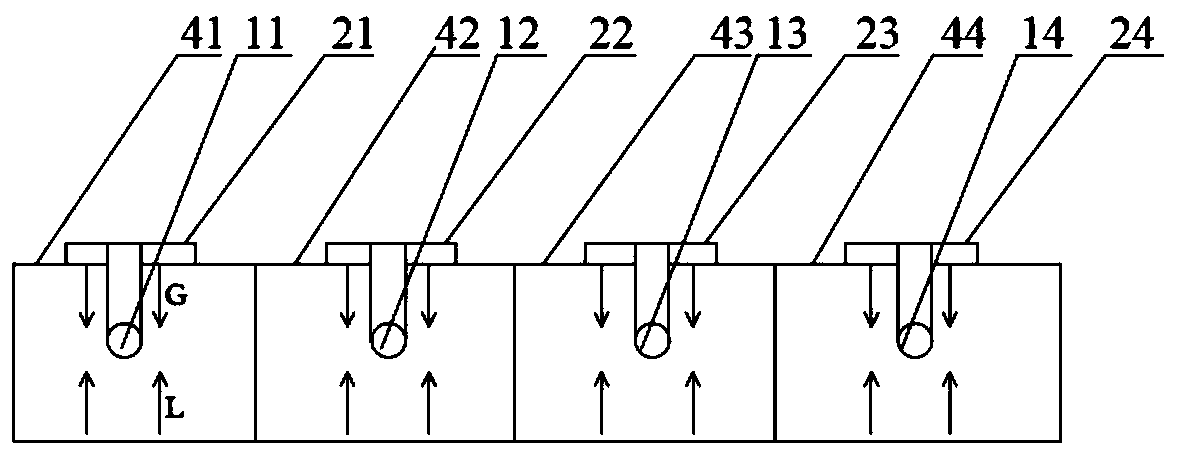

[0065] Such as image 3 , 4 As shown, the structure of the multi-heating body alternate heating device of the present embodiment is such that a rectangular parallelepiped microporous ceramic oil guide body 3 is set, and a rectangular atomizing surface 4 is arranged on the oil guide body 3, and the oil guide body 3 has In the microporous structure, the capillary pores inside are mostly arranged in a vertical direction, so that the e-liquid flows from bottom to top in the oil guide body to the position of the atomization surface 4 . In order to set a plurality of heating elements on the atomizing surface 4, a non-oil-conducting belt is set in the oil-guiding body 3, which is used to divide the oil-guiding body 3 into four oil-guiding sections as 31, 32, 33, respectively. 34. The non-oil-conducting belt is a non-oil-conducting ceramic structure, which is integrally formed with the oil-conducting section. The atomized surface 4 is also divided into four parts accordingly, namel...

Embodiment 2

[0070] Such as Figure 5 to Figure 7 As shown, the present embodiment is based on the structure of a heating device in which a traditional oil-conducting cotton cylinder arranged vertically is used as an oil-conducting body.

[0071] Such as Figure 5 As shown, the atomizer is provided with a cylindrical atomizing core shell, and an oil-guiding cotton cylinder is arranged inside the atomizing core shell as the oil-guiding body 3, thus forming a cylindrical atomization on the inner surface of the oil-guiding body 3. inner surface 4. And the heating element 2 is also a cylindrical shape, what the present embodiment uses is the heating element 2 that is made up of heating mesh, as Figure 6 As shown, each heating mesh is in the state of being cut longitudinally from the whole cylinder, and is divided into four independent parts. Defined as the first heating body 21 , the second heating body 22 , the third heating body 23 and the second heating body 24 . Wherein the first to t...

Embodiment 3

[0074] Product Example 3: This example still uses the cylindrical atomizer structure of Example 2, but the heating element no longer uses an axially segmented structure, but a longitudinally segmented structure, that is, the overall heating element is divided into Four heating elements, each of which is a spiral heating wire, are arranged longitudinally on the surface of the oil guide body of the atomizer, and insulating support frames are set between adjacent heating elements to connect and play a supporting role, so that the heating elements There is a certain interval between them. And each heating body is provided with an independent connection electrode, which is independently connected with the heating control device. It's just that in the specific connection, one of the ends can be set as a common electrode state, so as to reduce the number of connected electrodes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com