Mechanical planting method for sugarcanes with super-wide line spacing

A planting method and sugarcane technology, which are applied in the fields of botanical equipment and methods, sugarcane cultivation, agricultural machinery and implements, etc., can solve the problems of inability to guarantee the growth space of sugarcane, inability to reduce costs, low income, etc., and achieve improved planting efficiency, The effect of improving efficiency and sucrose content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

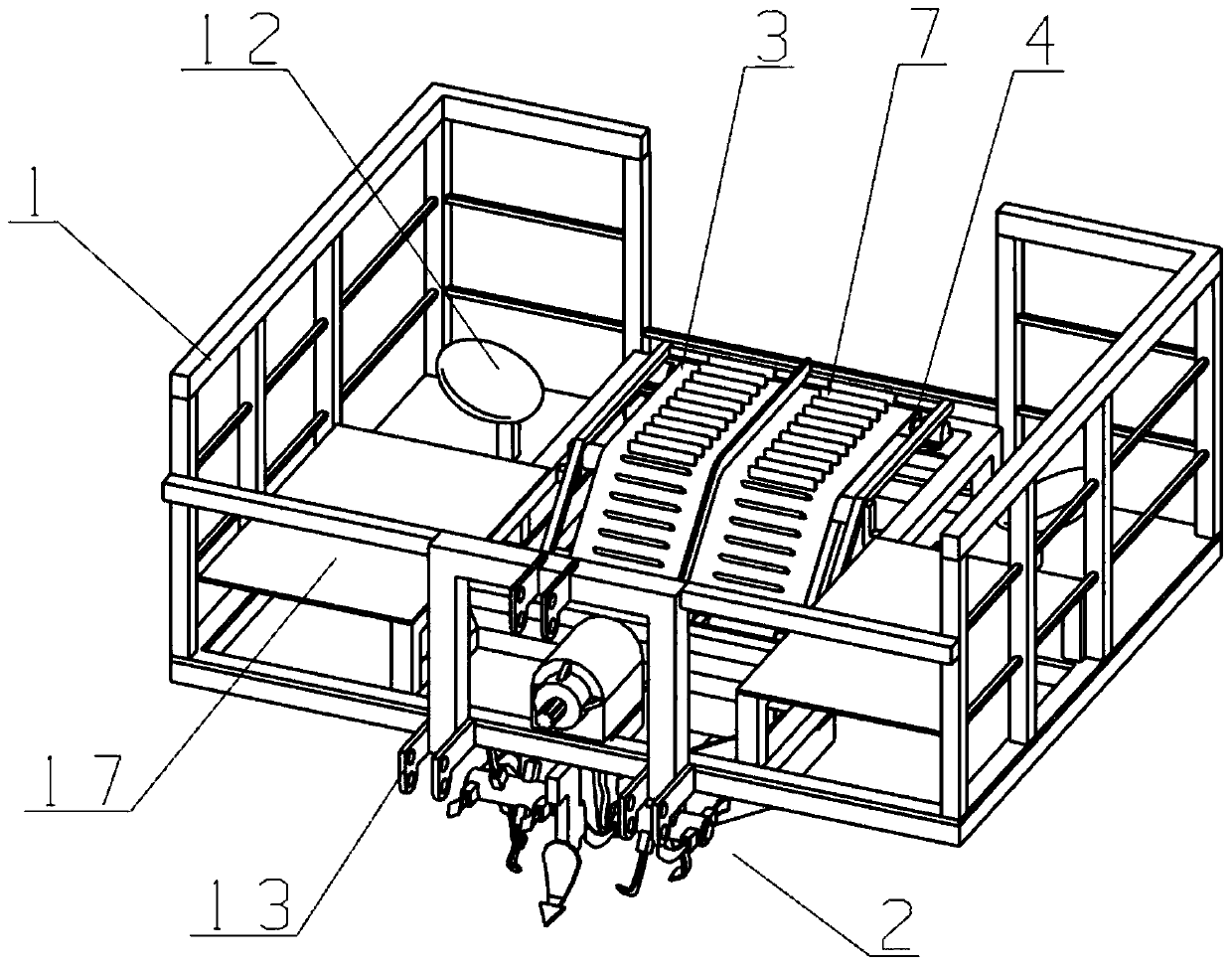

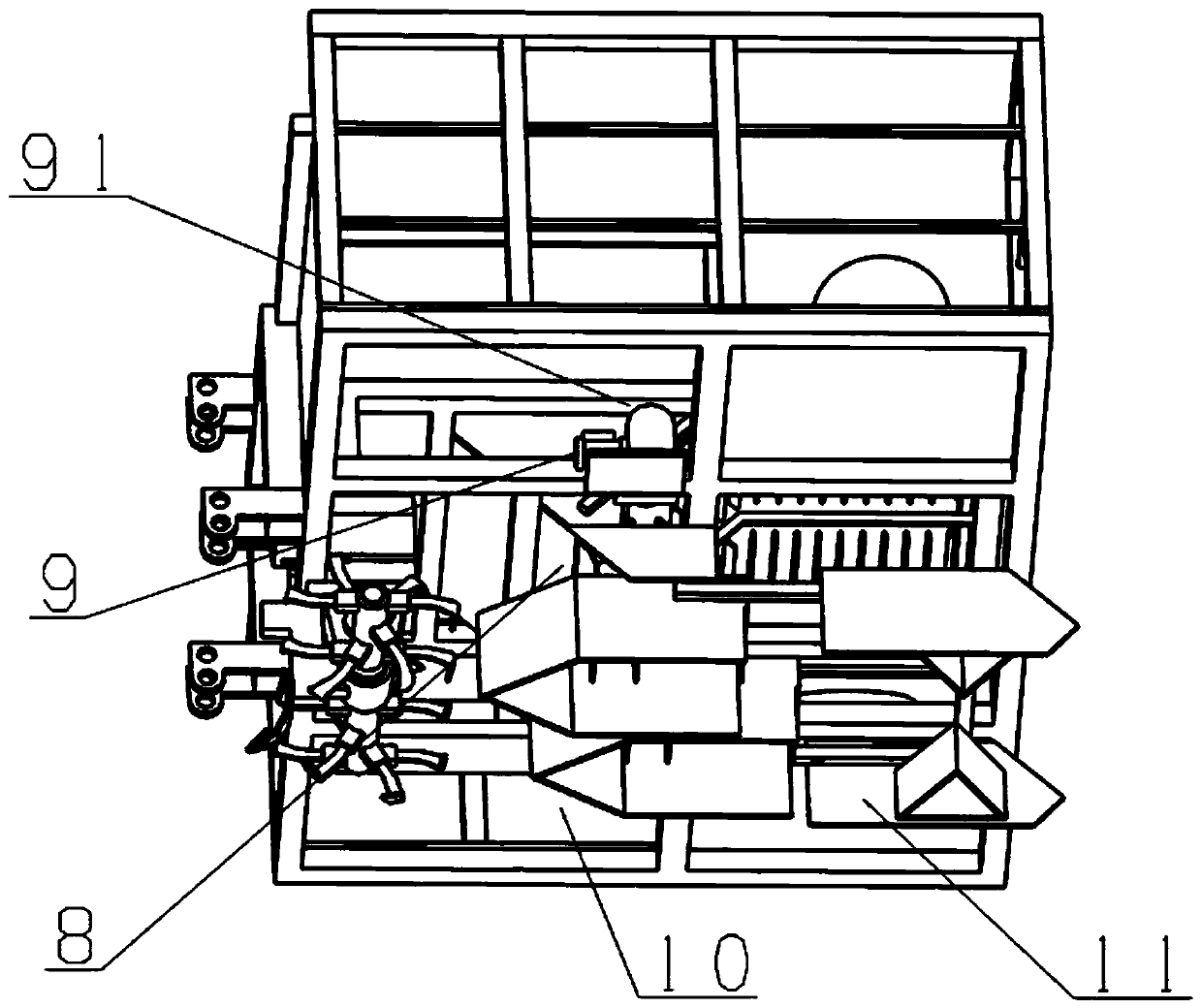

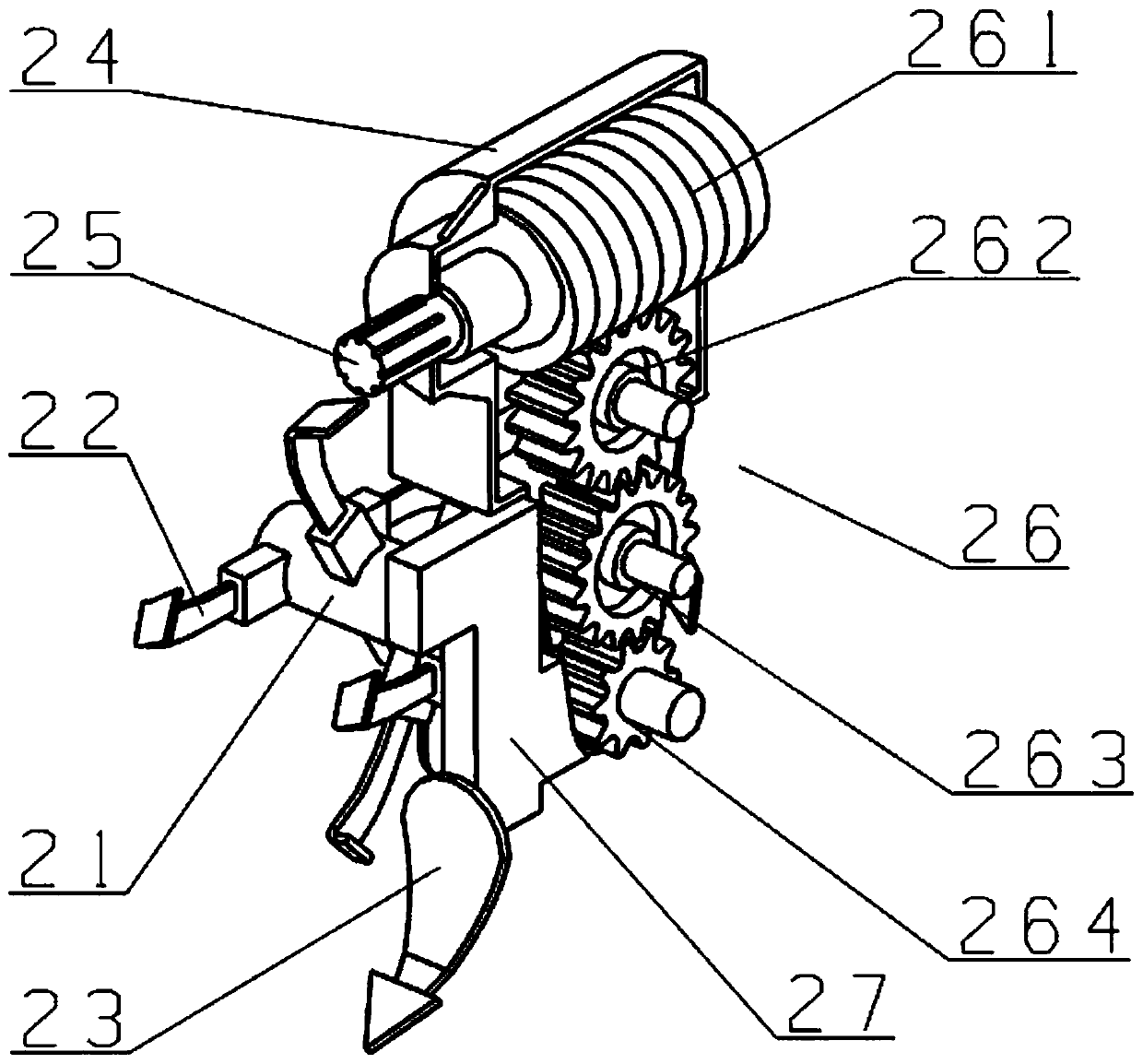

[0055] Such as Figure 1 to Figure 7 As shown, the horizontal row precision seeder in this embodiment includes: a frame 1, a rotary tiller 2, a conveyor belt 3, a roller 4, a conveyor frame 5, a guide plate 6, a bar 7, and a planter 8 , hydraulic pump 9, opener 10, backfill plate 11, seat 12, connecting seat 13, connecting rod 14, hydraulic pump gearbox 15, fixed seat 16, bottom plate 17, bulldozer plate 18, horizontal shaft 21, rotary tillage Knife 22, rotary tillage plow 23, rotary tillage gearbox 24, power input shaft 25, rotary tillage gear set 26, rotary tillage plow frame 27, first worm 261, first gear 262, second gear 263, third gear 264 , slide plate 81, seed opening 82, soft plate 83, hydraulic pump gear set 91, fourth gear 911, second worm 912, next seed chamber 101, seed inlet 102, seed discharge port 103, ditching plate 104; The bottom of frame 1 is provided with base plate 17, is provided with fence around, and the front end of frame 1 is welded with three connec...

Embodiment 2

[0063] The 2,000-acre sugarcane double-high base in Guangxi adopts mechanized planting of sugarcane with ultra-wide row spacing. The planting variety is Guitang No. 49. The planting method includes the following steps:

[0064] Step S1: Select sandy loam soil preparation with arable soil layer thickness of 60 cm or more, pH 5.0-7.0, sugarcane field machine plowing road surface width ≥ 4 m, and height difference between the field and the road surface ≤ 5 cm, specifically including:

[0065] A1: For stubble removal, use a 165-horsepower tractor to pull a heavy harrow with a farming width of 2.5m, and chop the weeds, cane leaves and cane heads on the ground, with a length of 8-12cm, a crushing rate of ≥90%, and loosen the topsoil. , depth 15cm.

[0066] A2: To level the land, use a tractor with 165 horsepower to pull a grader with a tillage width of 3.6 to level the sugarcane field, and level it according to the slope and terrain.

[0067] A3: Deep loosening and ditching, use a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com