Surface protection film

A surface protection film and protective layer technology, which is applied in the direction of protective clothing, protective equipment, film/sheet adhesive, etc., can solve the problems of discoloration and expansion of the surface protection film, achieve excellent plasticizer resistance, and handle Excellent performance and good self-healing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0115] "Example 1"

[0116] Add 100 g of succinate polyol (manufactured by Tosoh Co., Ltd., trade name: ON-300), 10 g of trimethylolpropane, 32.6 g of xylylene diisocyanate (Mitsui Chemicals Co., Ltd. Made by the company, trade name: Takenate (Takenate) T500), and 50 ppm of an organotin compound were stirred and mixed to prepare a material composition (α ratio: 0.95).

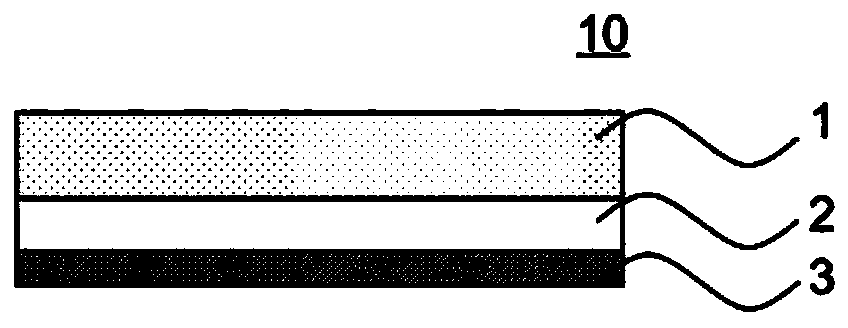

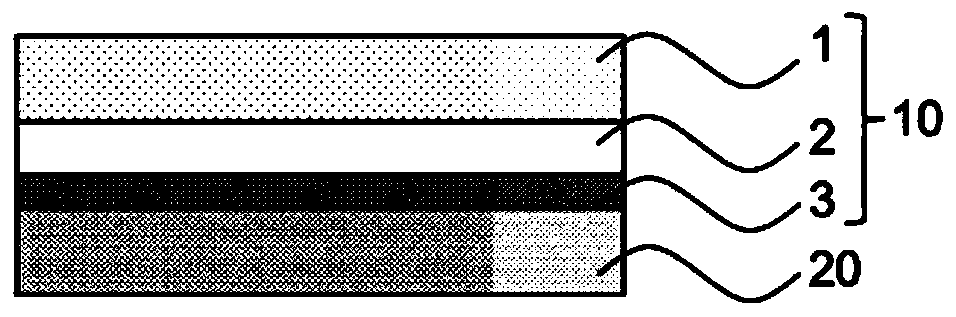

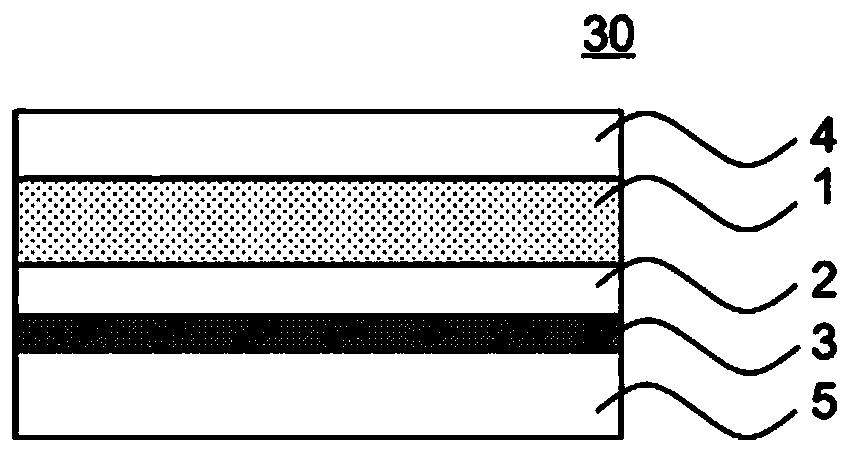

[0117] A laminate obtained by laminating a silicon-treated PET film with a thickness of 75 μm (equivalent to a release film) / a silicon-based adhesive layer with a thickness of 50 μm / a PET film with a thickness of 100 μm (equivalent to a transparent base film) was used as As the first gap maintaining member, a silicon-treated PET film (equivalent to a release film) with a thickness of 125 μm is used as the second gap maintaining member, and a succinic acid-containing polyester-based polyester film having a thickness of 100 μm is produced by the above-mentioned molding method. The surface protection film laminat...

Embodiment 2

[0118] "Example 2"

[0119] Except having made 15 g of trimethylolpropane and 43.7 g of xylylene diisocyanate, it carried out similarly to Example 1, and obtained the surface protection film laminated body.

Embodiment 3

[0120] "Example 3"

[0121] Except having used 5 g of cyclohexanedimethanol instead of trimethylolpropane, and made 17.4 g of xylylene diisocyanate, it carried out similarly to Example 1, and obtained the surface protection film laminated body.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com