Combined multi-channel end face sealing rotary compensator

A technology of rotary compensator and end face sealing, which is applied to expansion compensation devices for pipelines, pipes/pipe joints/pipes, adjustable connections, etc. Filling loss and other problems, to achieve the effect of long service life, high bearing strength, and enhanced sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with accompanying drawing and specific embodiment the present invention will be further described:

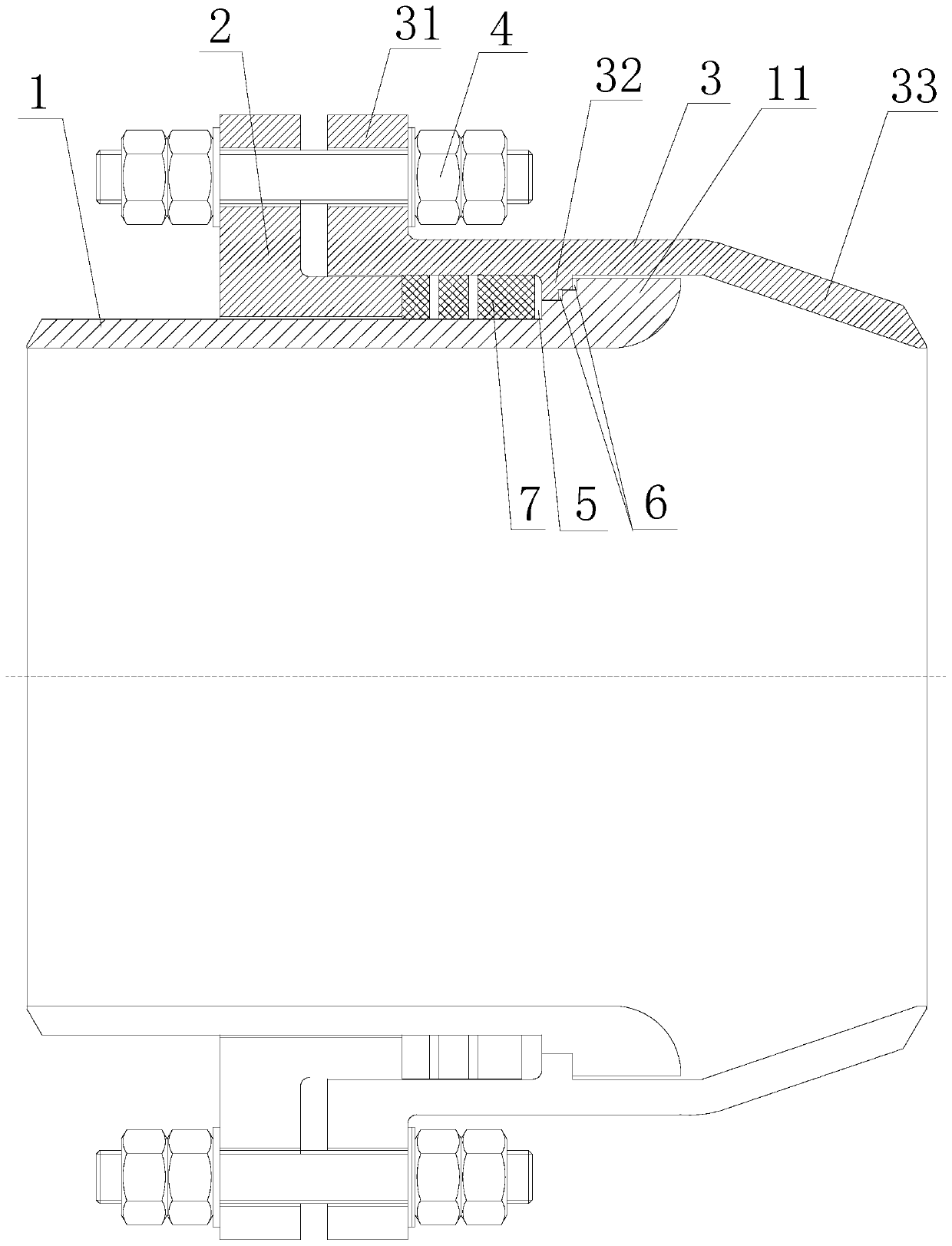

[0022] Such as figure 1 As shown, the combined multi-channel end face seal rotary compensator includes a rotary seat 3, a rotary core tube 1 and a packing gland 2. The inner surface of the inner surface of the rotating core tube 1 and the outer surface of the rotating core tube 1 form a packing sealing cavity, and a sealing packing is arranged in the sealing cavity. The inner wall of the rotating seat 3 is provided with an inner convex ring 32. The stepped outer boss 11 matched with the convex ring 32, the assembly gap formed between the outer boss 11 and the inner convex ring 32 is located in the middle of the bottom of the sealed cavity; the outer boss 11 of the rotating core tube 1 is at least There are two steps, and an end face sealing ring 6 is embedded between the side of the steps and the opposite surface of the inner convex ring 32 .

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com