Combined sealing connecting method for plastic pipes

A connection method and technology for plastic pipes, which are applied in the direction of pipe connection layout, pipe/pipe joints/pipe fittings, machinery and equipment, etc., can solve the problems of shortened service life, long construction time and low economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

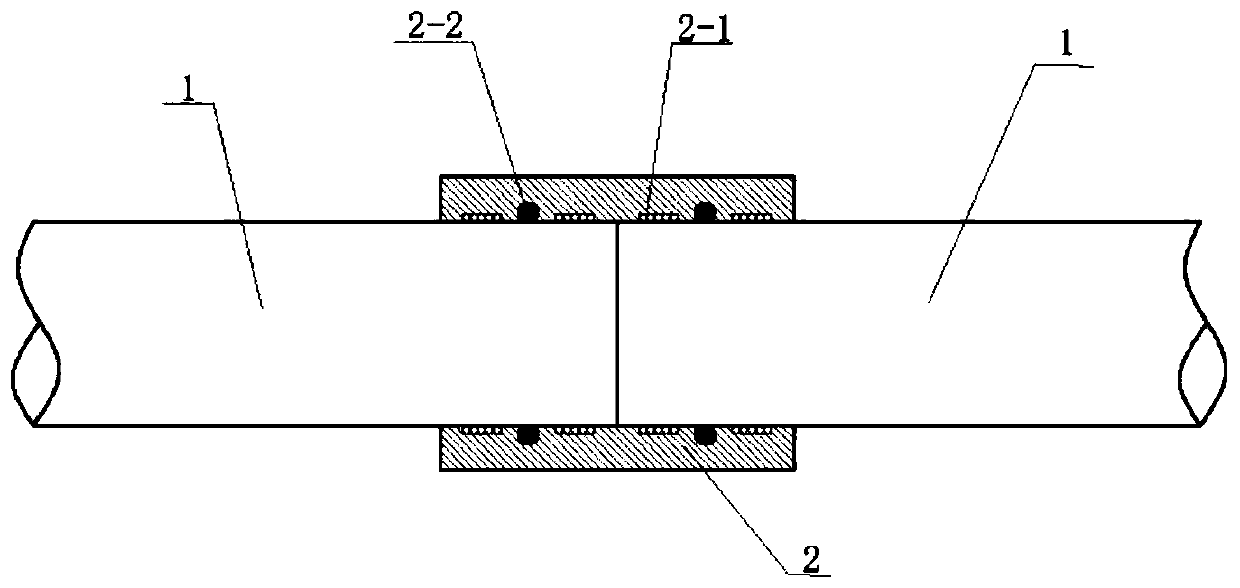

Embodiment 1

[0038] See attached figure 1 , four sets of heating elements of plastic pipes and two sealing rings combined sealing connection device, the plastic pipe combined sealing connection device includes plastic pipe 1, casing 2, heating element 2-1, sealing ring 2-2; the plastic The pipe includes a socket pipe 3 and a socket pipe 4; the connection relationship of the plastic pipe combined sealing connection device is: first place two plastic pipes 1 of the same diameter to be connected horizontally, and then install the connecting sleeve 2 on the inner wall Install the sealing ring 2-2 and the heating element 2-1, then put the connecting sleeve 2 on the left plastic pipe 1 first, and then connect the right plastic pipe 1 with the left plastic pipe 1, that is, the right end surface of the left plastic pipe 1 and the right The left end face of the plastic pipe 1 is docked, and after the docking is in place, the heating element 2-1 on the inner wall of the casing 2 is energized, and th...

Embodiment 2

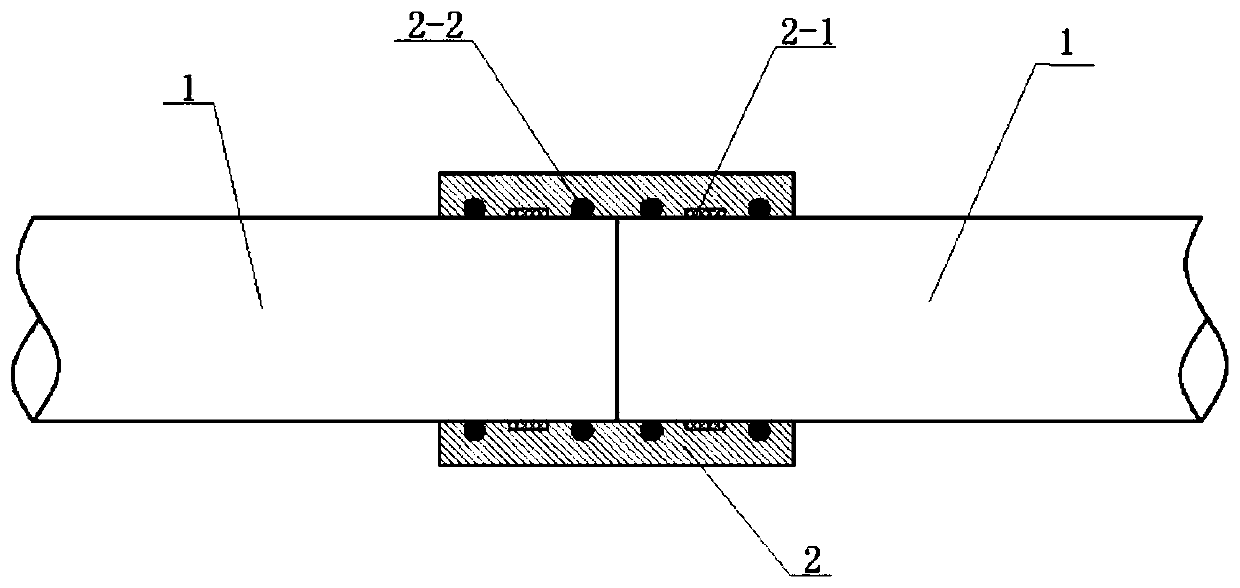

[0051] See attached figure 2 , Two sets of heating elements of plastic tubes and four sealing rings combined sealing connection device.

[0052] The sealing ring 2-2 installed on the inner wall of the casing is: four sealing rings 2-2 are installed.

[0053] The installation of the heating element 2-1 on the inner wall of the casing means: installing two sets of heating elements 2-1.

[0054] The rest is the same as above.

Embodiment 3

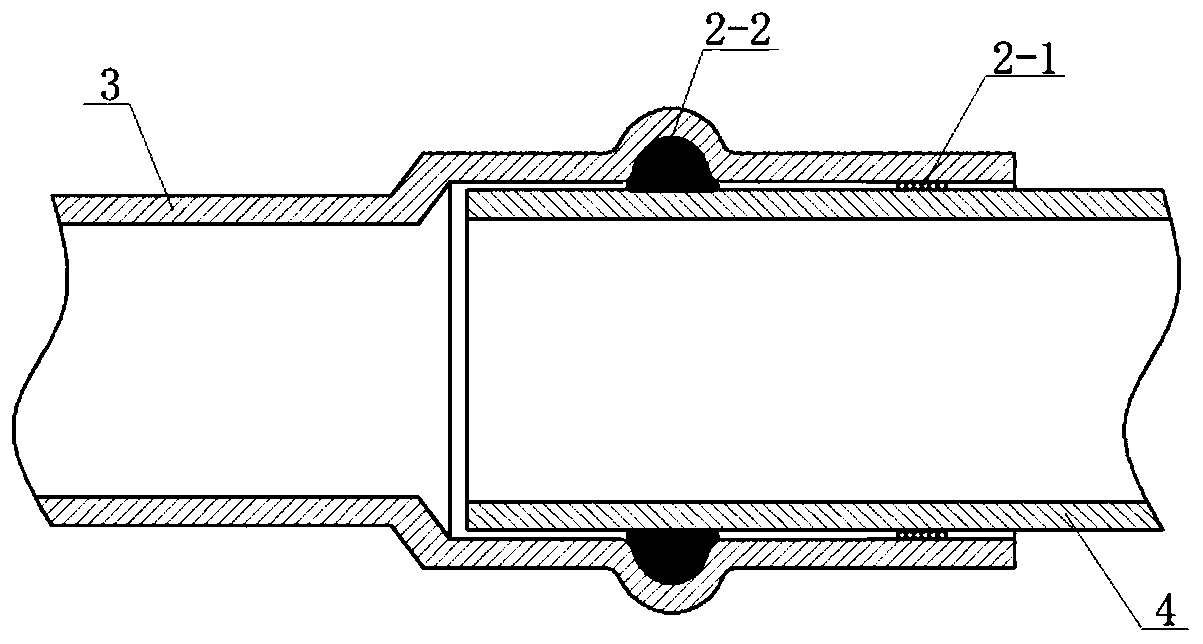

[0056] See attached image 3 , the plastic pipe 1 and the sleeve pipe 2 are combined into one, and one end of the plastic pipe manufactured is a socket pipe 3 with a socket.

[0057] The inner wall of the socket pipe 3 is provided with a sealing groove for installing the sealing ring 2-2; the socket pipe 3 is matched with the socket pipe 4, and the sealing ring 2-2 is installed at the junction of the socket pipe 3 and the socket pipe 4 and heating element 2-1.

[0058] The sealing ring 2-2 is a semicircular sealing ring.

[0059] The rest is the same as above.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com