Inorganic particle composite polyurethane synthetic leather and preparation method and application thereof

A technology of composite polyurethane and inorganic particles, which is applied in the field of polyurethane synthetic leather, can solve the problem of high VOC volatilization, achieve the effects of reducing VOC emissions, simple and easy preparation method, and reducing photothermal cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

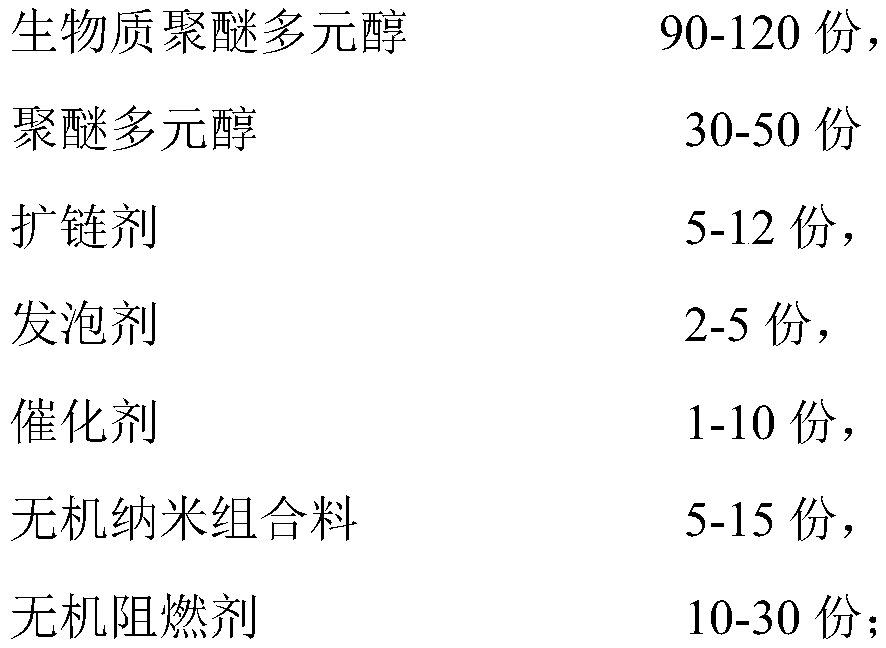

[0033] Composite material A comprises the component of following mass parts:

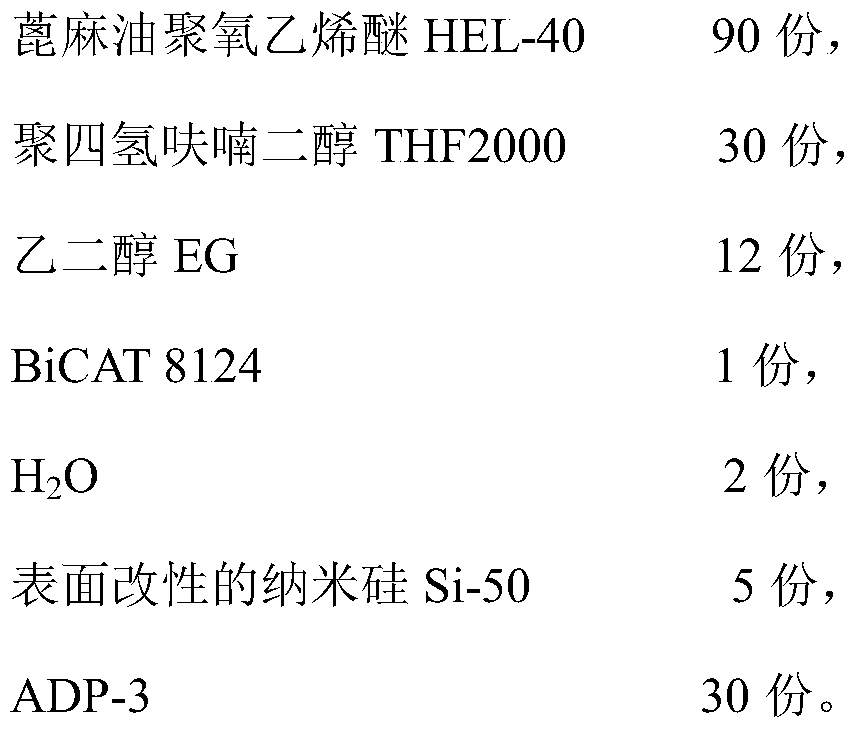

[0034]

[0035] After fully stirring the above-mentioned castor oil polyoxyethylene ether HEL-40, polytetrahydrofuran glycol THF2000, ethylene glycol EG, and catalyst BiCAT 8124, heat up to 60°C, add foaming agent water, and cool down after the moisture content is ≤300ppm to 40°C, and then ultrasonically disperse the surface-modified nano-silicon Si-50 and the modified inorganic retardant fuel ADP-3 evenly, stir evenly, then vacuum defoam, seal the package for use, and stand still to obtain the composite material A material.

[0036] Preparation of material B of the combination: Mix the liquid MDI-100 at a temperature of 60°C, fully stir to obtain material B, let it stand still, and set it aside.

[0037] Preparation of inorganic particle composite polyurethane synthetic leather: coating surface layer polyurethane slurry on release paper, drying at 130°C to obtain solvent-based surface layer.

...

Embodiment 2

[0041] Composite material A comprises following mass parts:

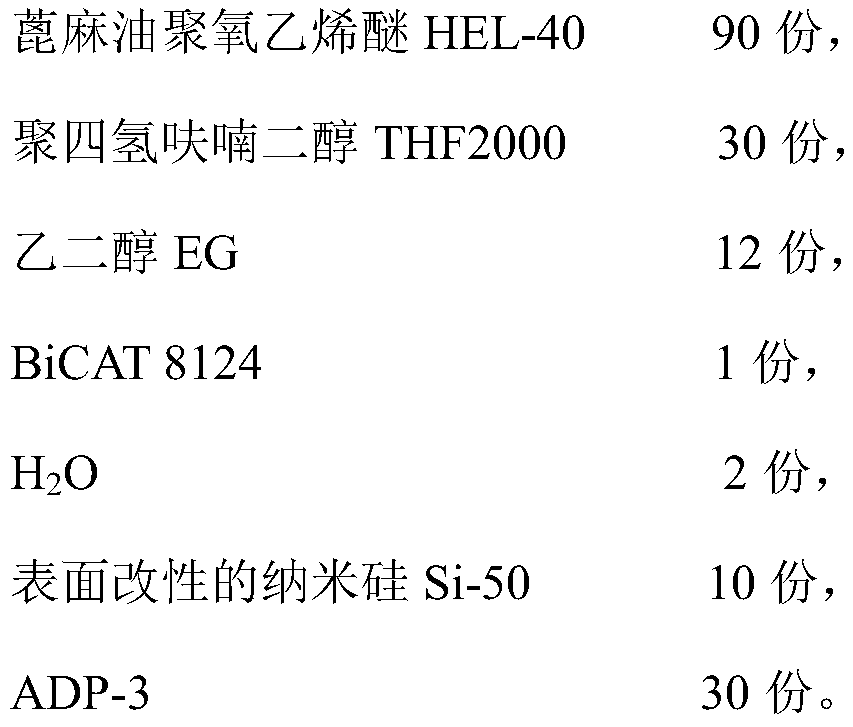

[0042]

[0043] After fully stirring the above-mentioned castor oil polyoxyethylene ether HEL-40, polytetrahydrofuran glycol THF2000, ethylene glycol EG, and catalyst BiCAT 8124, heat up to 60°C, add foaming agent water, and cool down after the moisture content is ≤300ppm to 40°C, and then ultrasonically disperse the surface-modified nano-silicon Si-50 and the modified inorganic retardant fuel ADP-3 evenly, stir evenly, then vacuum defoam, seal the package for use, and stand still to obtain the composite material A material.

[0044] Preparation of material B of the combination: Mix the liquid MDI-100 at a temperature of 60°C, fully stir to obtain material B, let it stand still, and set it aside.

[0045] The preparation of the inorganic particle-composite polyurethane synthetic leather: coating the polyurethane slurry of the surface layer on the release paper, drying and molding at 130°C to obtain the solvent-b...

Embodiment 3

[0049] Composite material A comprises following mass parts:

[0050]

[0051] After fully stirring the above-mentioned castor oil polyoxyethylene ether HEL-40, polytetrahydrofuran glycol THF2000, ethylene glycol EG, and catalyst BiCAT 8124, heat up to 60°C, add foaming agent water, and cool down after the moisture content is ≤300ppm to 40°C, and then ultrasonically disperse the surface-modified nano-silicon Si-50 and the modified inorganic retardant fuel ADP-3 evenly, stir evenly, then vacuum defoam, seal the package for use, and stand still to obtain the composite material A material.

[0052] Preparation of material B of the combination: Mix the liquid MDI-100 at a temperature of 60°C, fully stir to obtain material B, let it stand still, and set it aside.

[0053] The preparation of the inorganic particle-composite polyurethane synthetic leather: coating the polyurethane slurry of the surface layer on the release paper, drying and molding at 130°C to obtain the solvent-b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com