A method for preparing vanadium-iron alloy by magnesium-aluminum composite thermal reduction of vanadium oxide

A technology for vanadium ferroalloy and vanadium oxide, applied in the field of magnesium-aluminum composite thermal reduction of vanadium oxide to prepare vanadium ferroalloy, can solve the problems of large metal aluminum, consumption, consumption of large lime, etc. The effect of the amount of slag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

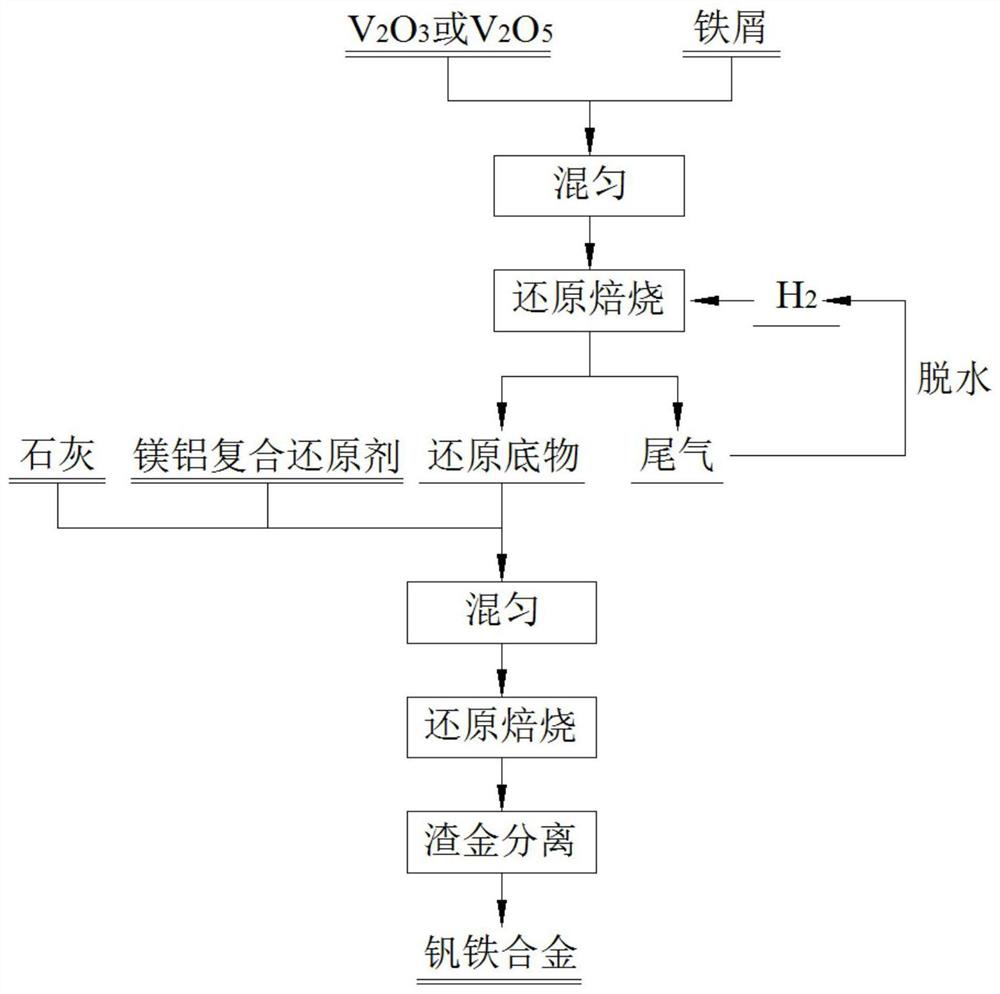

[0027] Embodiment 1: see Figure 1-Figure 3 , a method for preparing vanadium-iron alloy by magnesium-aluminum composite thermal reduction of vanadium oxide, comprising the following steps:

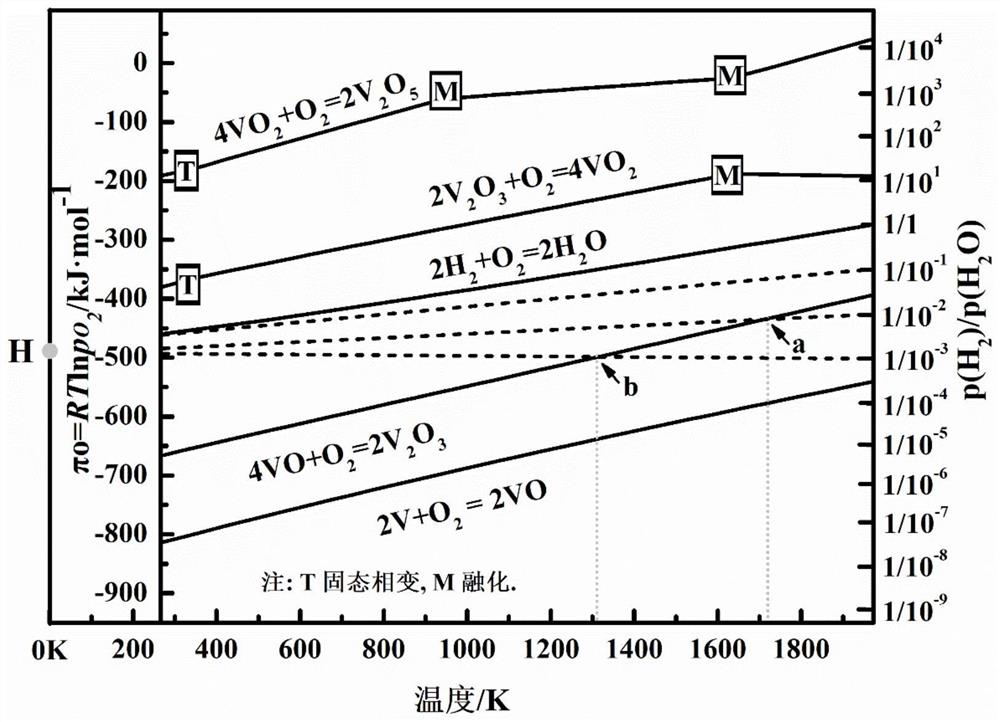

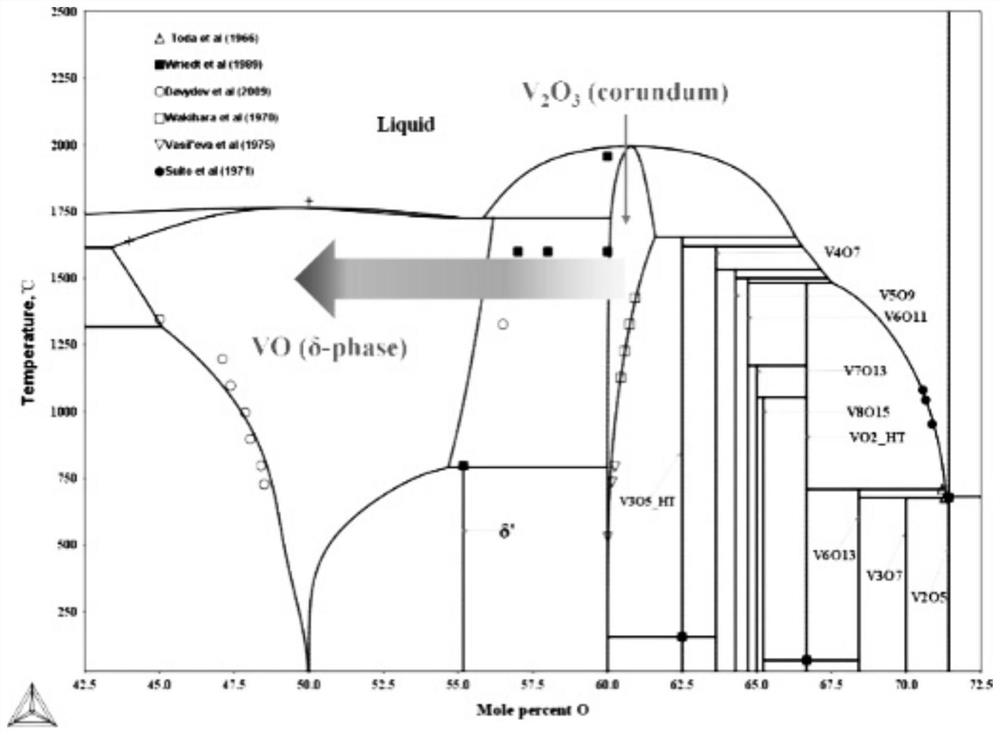

[0028] S1. Put V 2 o 5 or V 2 o 3 Put it into the pre-reduction device, and then pass H into the pre-reduction device 2 , using H 2 will V 2 o 5 or V 2 o 3 Reduction to get VO, at the same time add an appropriate amount of iron filings to the pre-reduction equipment during the reduction, iron filings in H 2 Under the action of being reduced to iron simple substance;

[0029] S2. Mix the VO obtained by pre-reduction with magnesium-aluminum composite reducing agent and lime, place it in a reducing atmosphere, and perform reduction roasting at 2000° C. to fully react;

[0030] The amount of magnesium-aluminum composite reducing agent required when the production capacity of vanadium-ferroalloy is one ton is: n Mg =2.37589kg / mol, m Mg =57.758kg, n Al =4.95971kg / mol, m Al =133.8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com