Power dividing type kinetic energy recovery system and working method thereof

A kinetic energy recovery system and shunt technology, applied in the direction of brakes, electric vehicles, vehicle energy storage, etc., can solve the problem of low battery life of kinetic energy recovery systems, and achieve the effect of improving battery performance, smoothing kinetic energy recovery actions, and improving bearing capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

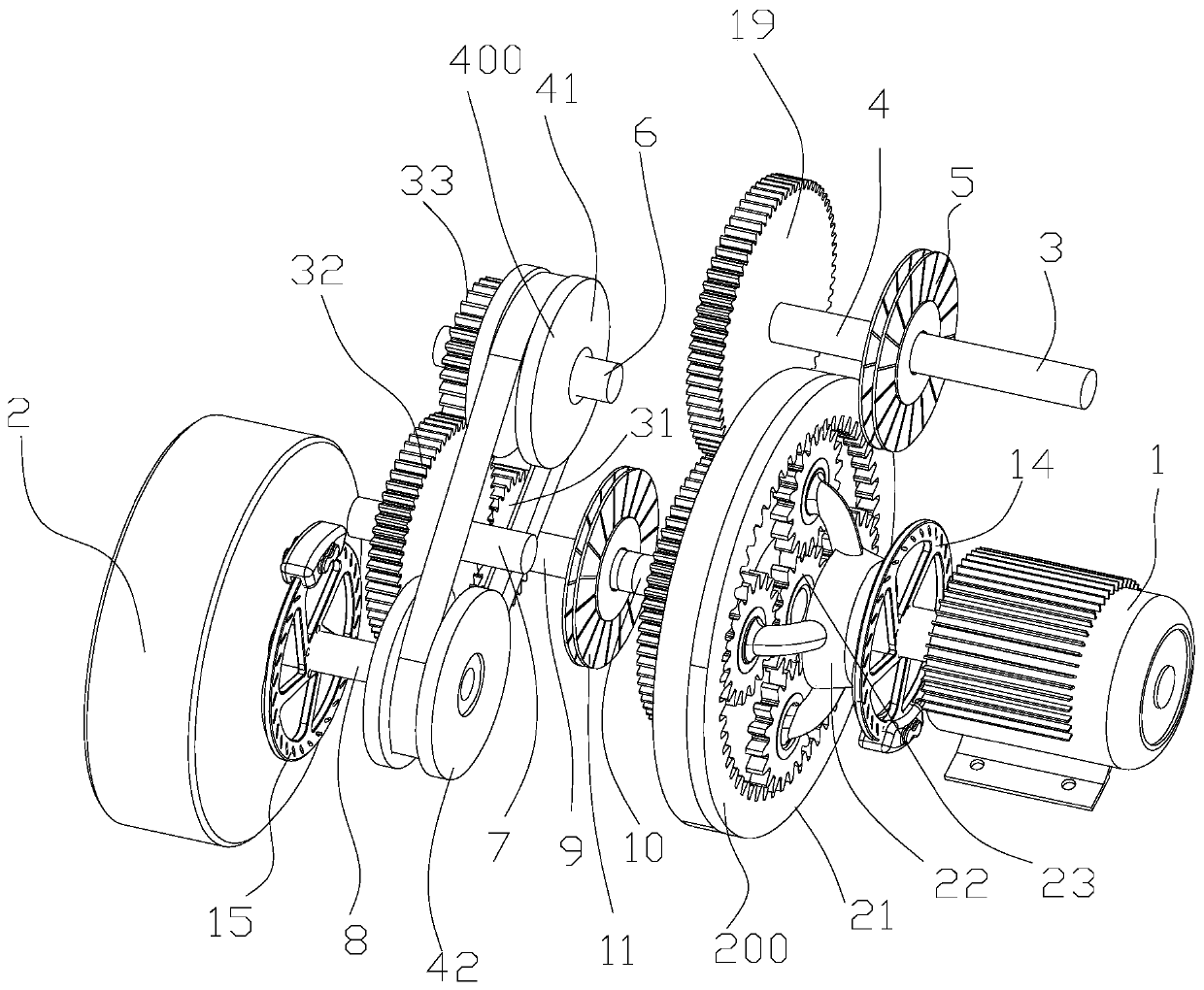

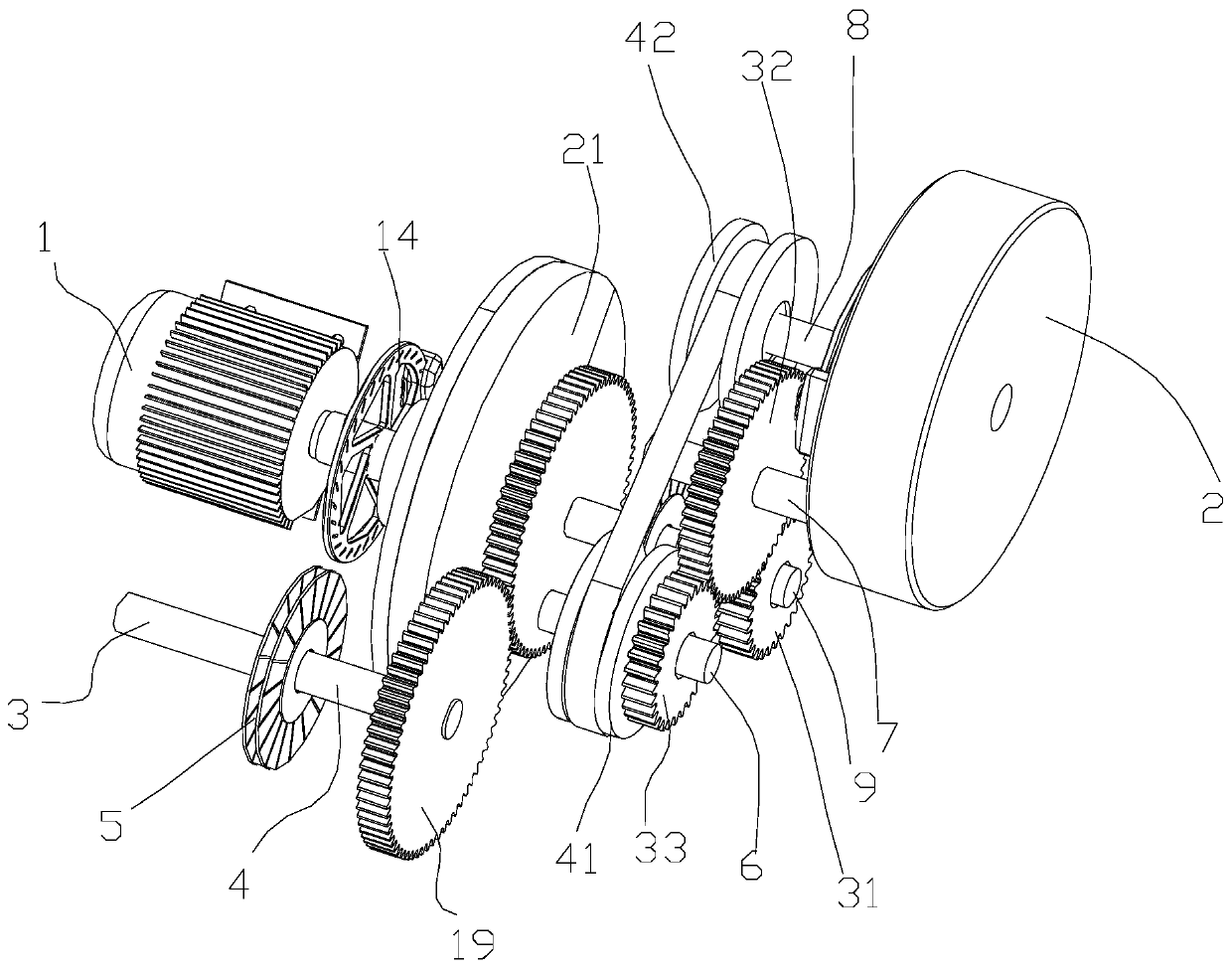

[0035] Such as Figure 1~2 , a power split type kinetic energy recovery system, comprising an engine output shaft 3 and a planetary gear train input shaft 4 and an engine clutch 5 connected between them, the planetary gear train input shaft 4 is fixed with an input gear 19,

[0036] The input gear 19 is connected with a planetary gear reducer 200, the output end of the planetary gear reducer 200 is connected with the motor 1 through the planet carrier 22, the input end of the planetary gear reducer 200 is connected with the transmission output shaft 10, and the transmission output shaft 10 passes through the flywheel The clutch 11 is connected with the transmission input shaft 9, and the first gear 31 is fixedly installed on the transmission input shaft 9. The first gear 31 is connected with the driving bevel 41 of the CVT continuously variable transmission 400 and the driven cone of the CVT continuously variable transmission 400 through the intermediate gear set. The wheel 42...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com