Friction stir welding stirring tool system capable of achieving trailing intensive cooling and flash removing

A technology of friction stir welding and stirring tools, which is applied in the direction of manufacturing tools, other manufacturing equipment/tools, welding equipment, etc., can solve the problems of friction stir welding joint thinning, excessive milling, and unfavorable joint mechanical properties, etc., to achieve Save manufacturing cost, ensure milling effect, and improve cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Welding of 2024 aluminum alloy sheets.

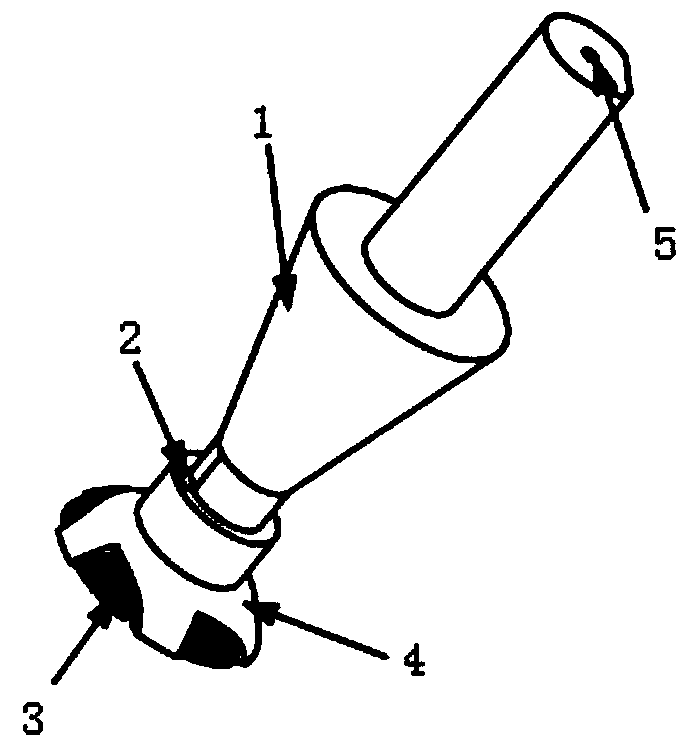

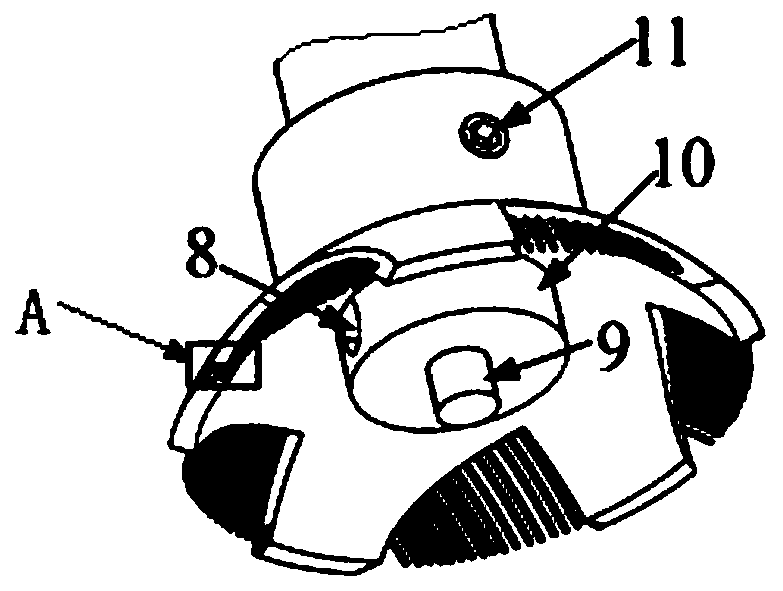

[0040]First determine the type of cooling medium. In this embodiment, the cooling medium is dry ice. According to the cooling medium, select the knife holder 4 without the water outlet 12, and set the knife holder 4 coaxially on the stirring head 1 through the ring connection end of the knife holder 4. , and the circumferential position is defined by the flat key 2, and then the tool holder 4 and the stirring head 1 are fixed by the first top wire 11; the installed stirring head 1 is inserted into the center hole of the main shaft sleeve 14 through the clamping end as a whole , and a sealing gasket is installed between the end face of the conical frustum of the stirring head 1 and the lower end face of the main shaft sleeve 14, and the stirring head 1 and the main shaft sleeve 14 are relatively fixed through the second jacking wire 15 on the main shaft sleeve 14, and the main shaft shaft A sealed bearing 16 is installed in the ho...

Embodiment 2

[0042] Welding of 7075 aluminum alloy sheets.

[0043] In this embodiment, the horizontal compensation method is used for welding, that is, there is a compensation boss at the weld seam, and the height of the boss is 0.2mm; when welding, the pressing amount of the stirring head 1 is 0.2mm from the upper surface of the boss, so as to realize welding without thinning , the inclination angle of the main shaft is 2.5°; the distance between the lower end surface of the tool holder 4 hemispherical end and the end surface of the shaft shoulder 10 of the stirring head 1 is 0.2mm, and the angle α between the end surface of the tool holder 4 hemispherical end and the horizontal plane is 2.5°; other The part is the same as that of Embodiment 1; friction stir welding without burr and thinning is realized while chilling with welding.

Embodiment 3

[0045] Welding of 1060 aluminum alloy.

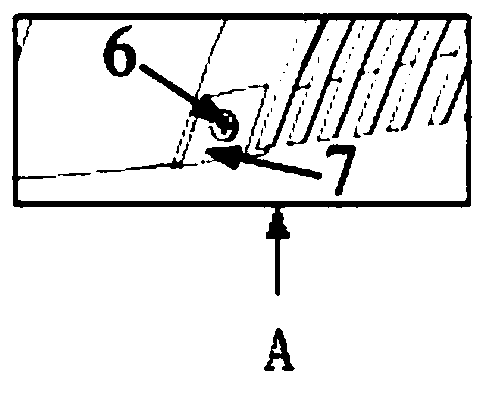

[0046] In this embodiment, when welding, the downward pressure of the stirring head 1 is 0.1 mm, the inclination angle of the main shaft is 2.5°, and the angle α between the hemispherical end surface of the tool holder 4 and the horizontal plane is 2.5°; in this embodiment, due to the 1060 aluminum The alloy material is relatively soft, and the flash is removed in the form of no blade; the milling cutter mounting screw 6 and the milling blade 7 are removed. Others are the same as in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com