Automatic repetition measurement machine and method for main boards

A mainboard, automatic technology, applied in the direction of measuring electricity, measuring devices, measuring electrical variables, etc., can solve the problems of increased failure rate, false detection, low efficiency, etc., to reduce the probability of false detection and improve the efficiency of retesting. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

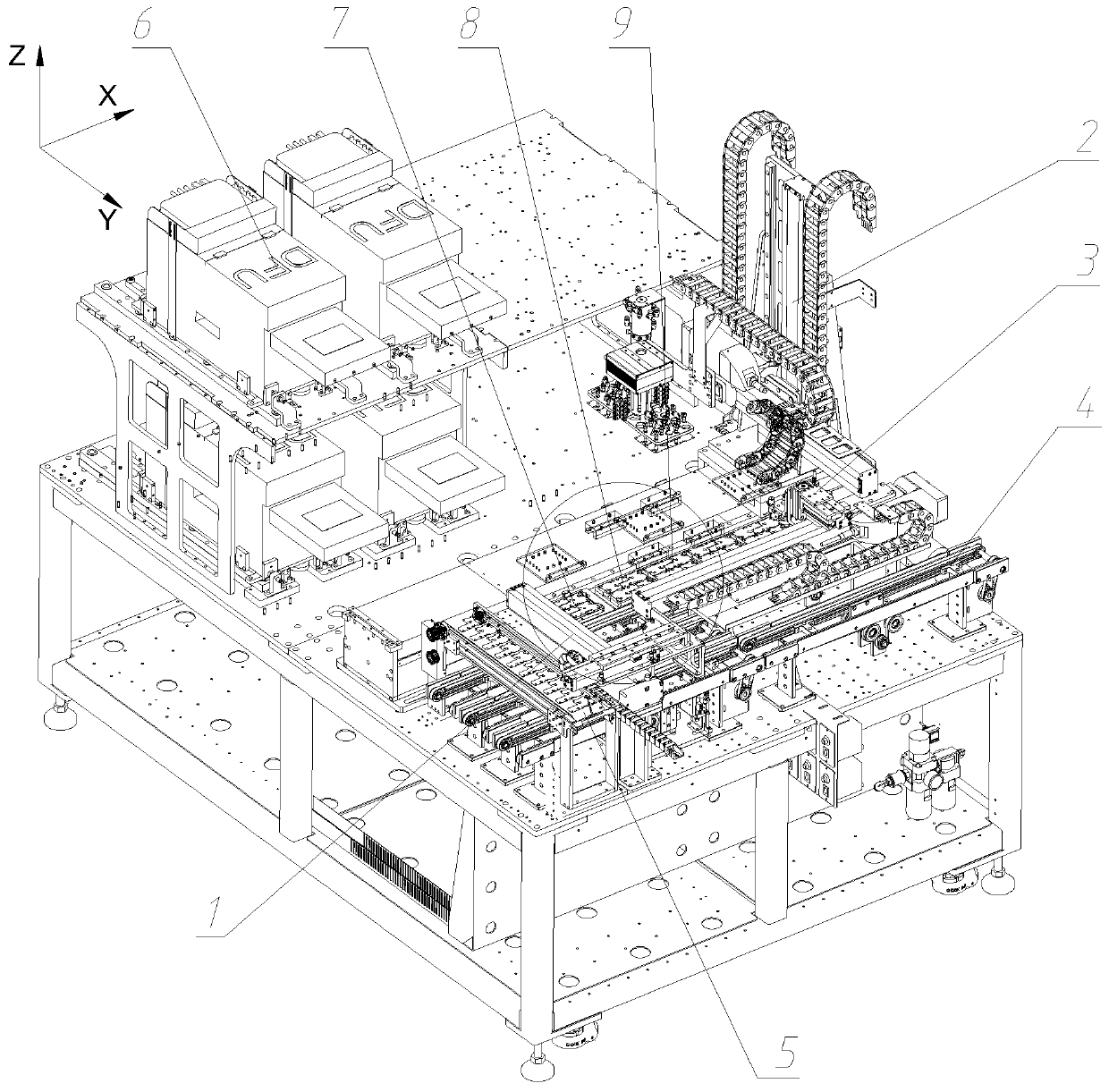

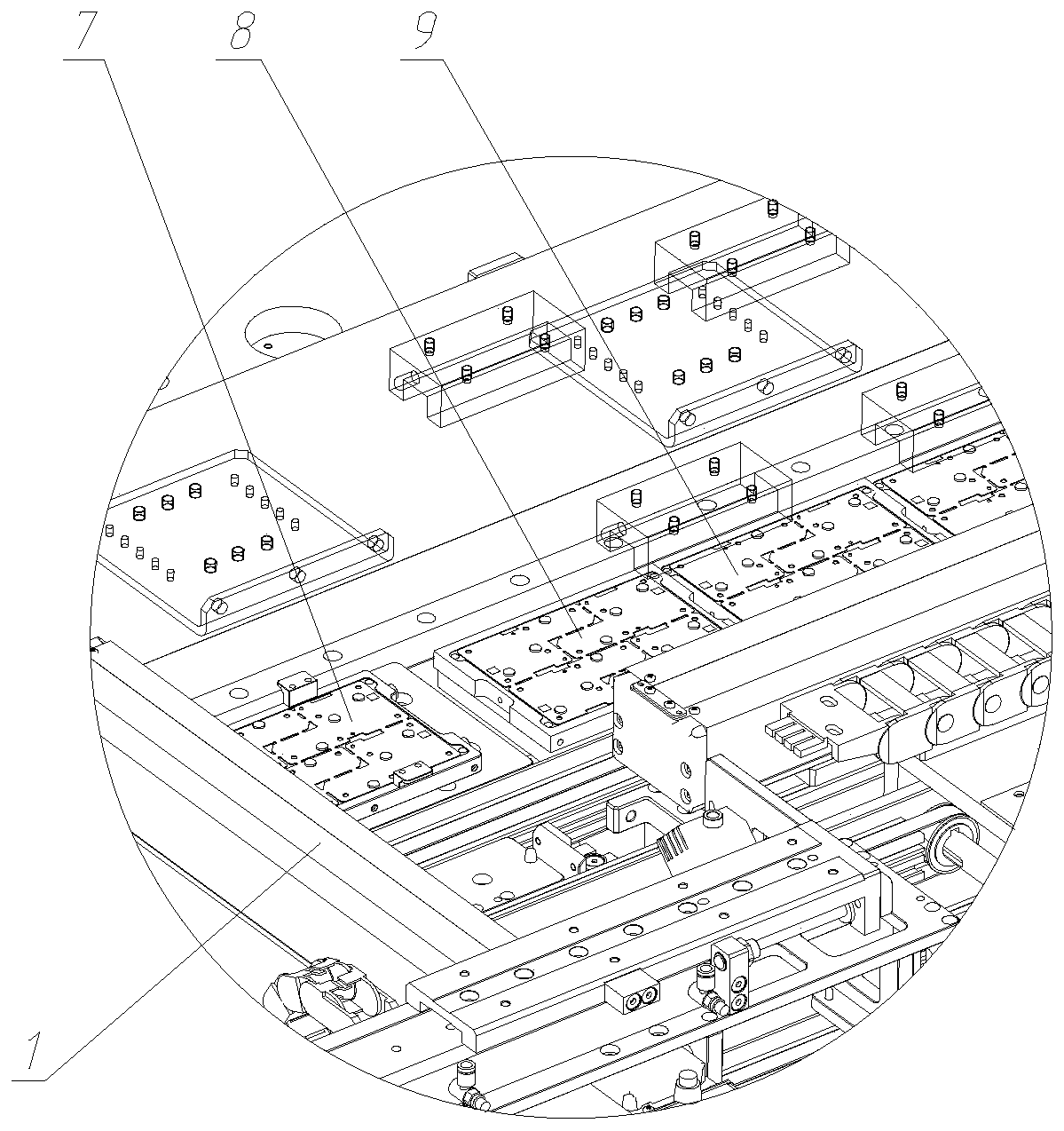

[0085] Such as figure 1 , figure 2 As shown, a kind of mainboard automatic retesting machine is provided in the present embodiment, including a frame, on which a transmission track 4, a manipulator mechanism, a mainboard storage position, a testing mechanism 6 and an output mechanism 5 for unqualified products in three times of detection are arranged on the frame, The transmission track 4, the manipulator mechanism, the testing mechanism 6 and the output mechanism 5 for unqualified products after three times of detection are arranged around the storage position of the main board;

[0086] The upper part of the frame is provided with a platform, and the conveying track 4, the manipulator mechanism, the testing mechanism 6 and the output mechanism 5 for unqualified products in the third inspection are all installed and fixed on this platform, forming a set of automatic main board testing equipment.

[0087] The specific functions of the above-mentioned main components are as f...

Embodiment 2

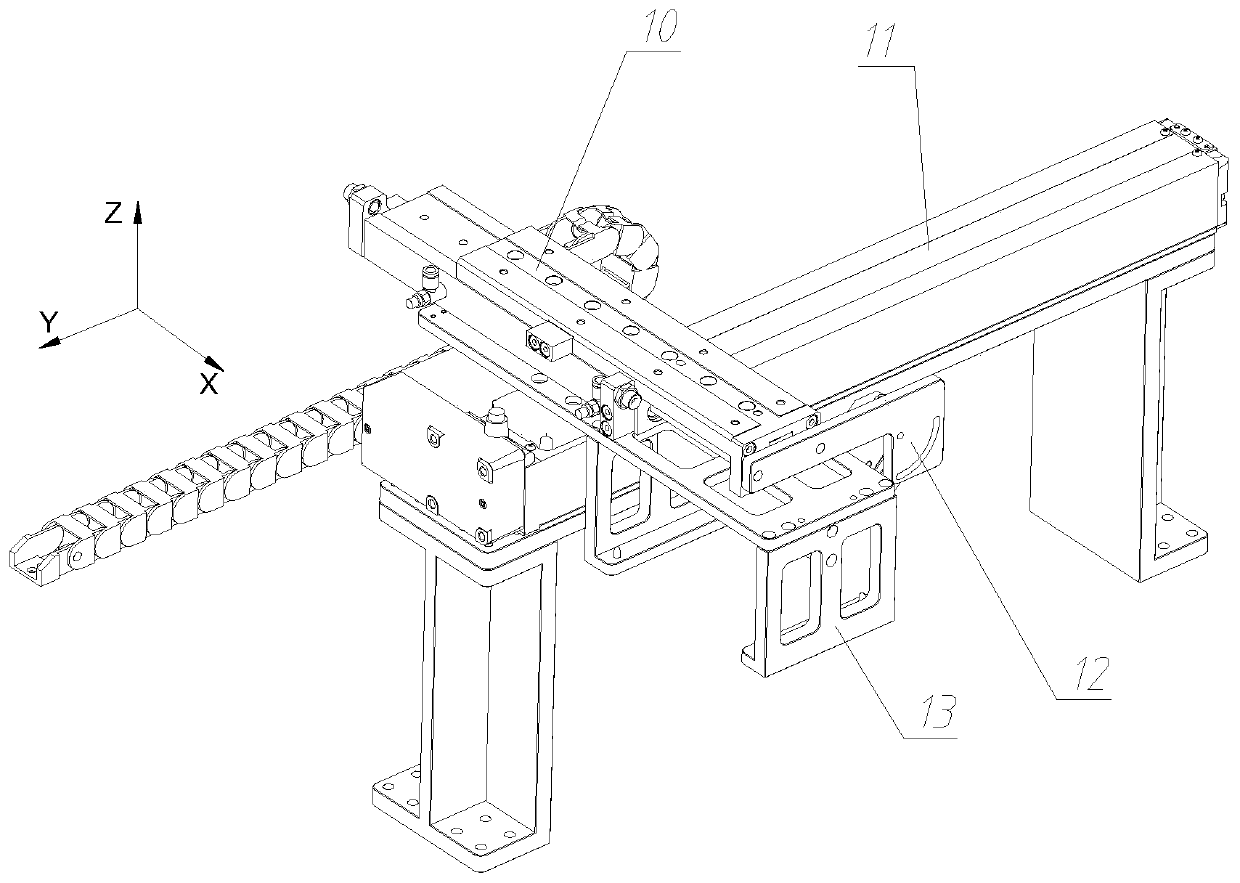

[0138] The difference from Example 1 is that, as Figure 9 As shown, in this embodiment, the positioning claw 13 is provided with linked jaws, which can clamp the circulation tooling from both sides of the circulation tooling, and directly transfer from the transmission track 38 of the main board to be tested, the transmission track 39 of the qualified main board, and the return track of the no-load circulation tooling. 40 to grab and release the transfer tooling.

[0139] In this way, there is no need to set jacking devices under the transmission track 38 of the main board to be tested, the transmission track 39 of the qualified main board, and the return track 40 of the no-load transfer tooling, which can simplify the structure of the automatic retesting machine for the main board.

[0140] Other structures of the mainboard automatic retesting machine in this embodiment are the same as those in Embodiment 1 or Embodiment 2, and will not be described again here.

Embodiment 3

[0142] can refer to Figure 10 As shown, this embodiment provides an automatic retesting method for mainboards, which can perform three tests on unqualified mainboards. This method is implemented by the automatic retesting machine for mainboards in Embodiment 1 or Embodiment 2.

[0143] Specifically, the method includes the following steps:

[0144] Step 10. Transfer the first circulation tool loaded with the main board from the transmission track of the main board to be tested to the pick-up position, then take out the main board that has passed the test in the testing organization, and exchange it with the main board to be tested in the first circulation tooling ;

[0145] Step 20. If the third unqualified main board is stored in the testing agency, take out the third unqualified main board and transfer it to the output mechanism for unqualified products in the third test; A transfer tooling for refilling;

[0146] Step 30. If the first circulating tooling is filled with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com