A Cable Driven Rotary Electromagnetic Energy Harvester

A rotary energy harvester technology, applied in the direction of electric components, electromechanical devices, electrical components, etc., can solve the problems of inability to collect energy, high resonant frequency, low output power, etc., to improve output power, operating frequency bandwidth, and cost low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

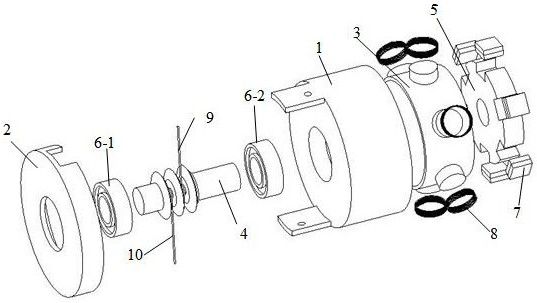

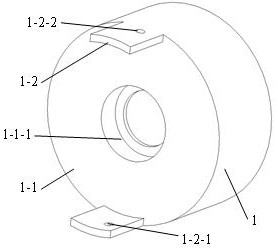

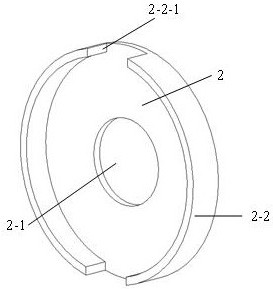

[0034] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 As shown, the technical solution of the present invention is realized in the following way: a rotary electromagnetic energy harvester driven by a cable is characterized in that it at least includes a side plate 2, a first bearing 6-1, a central rotating shaft 4, and a second bearing 6 -2, cylinder 1, inner cylinder 3, rotor 5; one side of the cylinder 1 is connected with the second bearing 6-2, the central shaft 4, the first bearing 6-1 and the side plate 2 in sequence, the On the other side of cylinder 1 there are inner cylinder 3 and rotor 5 in sequence; side plate 2, first bearing 6-1, central shaft 4, second bearing 6-2, cylinder 1, inner cylinder 3, and rotor 5 are coaxial in sequence Connection; the center of the cylinder 1 has a first through hole 1-1-1, and the first through hole 1-1-1 is coaxial with the cylinder 1; the center of the side plate 2 has a second through h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com